Peel Test to measure package openings and sealed strength

In the previous article, we wrote about the 180 degree peel test and the 90 degree peel test as the introduction to peel tests. The 180 degree and 90 degree peel tests measure the peel strength of adhesive tape and adhesive sheets. In this second article, we will introduce the 45 degree peel test and the T peel test as test methods used for package seals such as the cup form containers and snack packages.

*Click here for the article Part 1 “Introduction to Peel Tests: 180 Degree Peel Test / 90 Degree Peel Test”.

Packages for items such as foodstuffs must be sealed airtight during transportation, displayed in the stores, and should be opened easily by consumers. Especially with film packages (and paper containers also in recent years), heat sealing plays an essential role in the packaging industry, and the 45 degree peel test and T peel test that measures the peel strength are adopted by many packaging manufacturers. Part 2 introduces the measurement and evaluation methods for these tests.

*Heat Sealing is a processing method that welds films by applying heat and force.

45 degree Peel Test

First, we are introducing the 45 degree peel method. The test method is used to evaluate the openability of jelly cup containers and other similar products. The test is performed by picking up the sealed lid of a cup container and pulling it off at an angle (45 degrees) to the adhesive surface to measure the peeling force. Pinch the sealed lid and peel it off at a 45 degree angle to measure the peel force.

ISO 17480:2015 (Packaging – Accessible design – Ease of opening) defines “opening strength” as the numerical value of the part with the highest resistance force after peeling the entire surface.

On the other hand, due to the fact that it is not easy to maintain a 45 degree angle when peeling off the entire lid of some types of containers, and that the highest resistance force occurs at the beginning of the lid opening in many cases, the opening resistance evaluation only is also adapted in many cases.

In terms of opening force evaluation, more is needed to have a high opening strength (peeling force),

but more importantly it is required that the product can be opened with the optimum peeling force for the target consumers of the product. Packaging companies use the 45 degree peel test for R&D and quality control, deriving the optimum peel strength from interviews and panel tests.

The 45 degree Peel Test Features

・Measure the force required to open the film or paper lid of cup containers.

・Peeling off in a 45 degree direction is close to the movements in the actual practice.

・In most cases, the greatest resistance force occurs at the beginning of the opening.

Click here for the actual measurement of the jelly cup container lid opening test with the motorized test stand.

T Peel Test

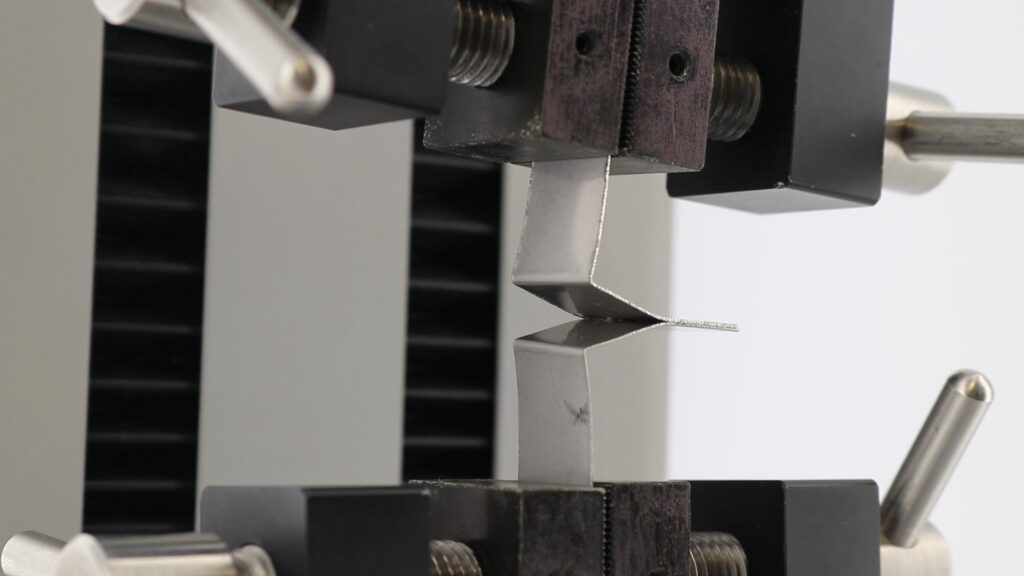

The T peel test method measures the heat seal strength of candy bags and pouch containers. In this test, which is called the T peel test, because the sample piece becomes T-shaped at the time of measurement, the peel strength is measured by pulling the film adhered by heat sealing as if peeling it off. The standard for using this peeling method is JIS Z1707:2019 (general rules for plastic films for food packaging), and measurements are performed using samples cut from the heat-sealed portion.

The T peel test evaluates sealed strength to confirm that the film is sealed adequately with sufficient force and openability to confirm that the film can be easily separated to open. The T peel test is not only for packages but also applies in other industries, such as measuring the welding strength of steel plates.

The T Peel Test Features

・Measures the force required to peel off the heat-sealed films.

・Used for heat seal strength measurements for quality control of snack bags and pouch containers.

・Evaluation of unsealability is also tested in the package form.

・Used also in other industries for testing with samples such as welding strength of steel plates.

*Click the following links for actual measurement videos

– Spot welding bonding strength test

Summary

In this issue, we have introduced the 45 degree and T peel tests, the test methods commonly used in the packaging industry. As mentioned in the introduction of the 45-degree peel test, it is not necessarily the case that the peel force is strong. Therefore, using measuring instruments to make accurate measurements is essential in quality control. We will introduce the “Coating Adhesion Test” in the next issue. . . Force Channel provides various articles on force measurement and forces. Please check out other articles also.