This is the third and final post on the Friction Testing series

; in addition to the “Paper Friction Test” and “Eyeliner and Artificial Skin Friction Test,” we are introducing the “Wear Test” to view the sample changes from the friction effects.

*Click here for the article “Introduction to Friction Testing (1) “Surface-to-Surface Contact Friction Testing

*Click here for the article “Introduction to Friction Testing (2) Surface and Point Contact Friction Testing

As mentioned in the first article, when two objects in contact move in a sliding motion, a force (frictional force) is generated that hinders the movement. One of the reasons for the occurrence of frictional force is the fine irregularities on the surfaces of the objects. The unevenness on the surfaces of the objects causes adhesion and scratching, leading to resistance to sliding movement. While adhesion and scratching between uneven surfaces cause frictional force, from a microscopic perspective, they also destroy the uneven surfaces of objects.

The surface destruction of an object mentioned above is called abrasions. The wear tests evaluate the wear characteristics by measuring the amount of wear (changes in volume and weight) and physical property changes (Frictional Forces, Coefficient of Friction, Gloss, etc.).

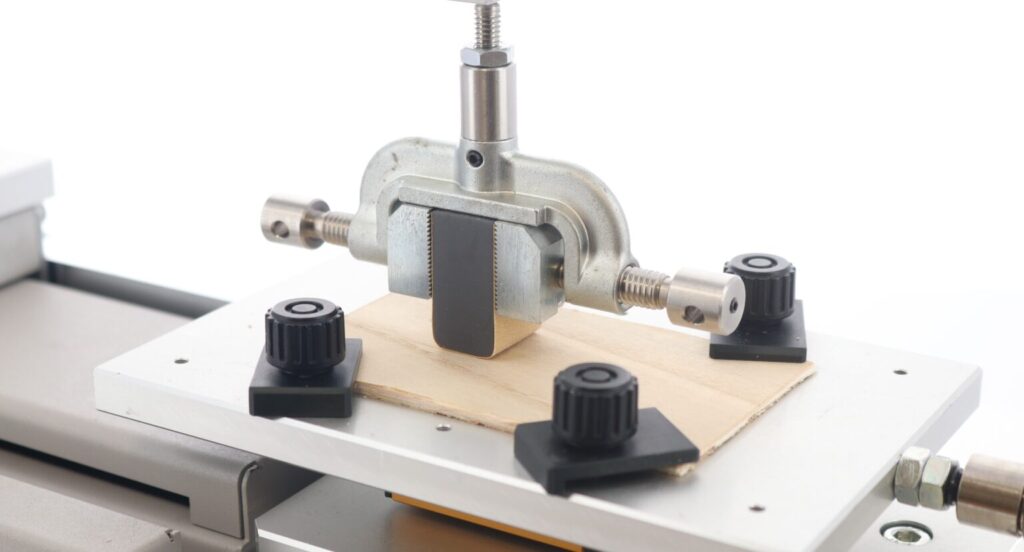

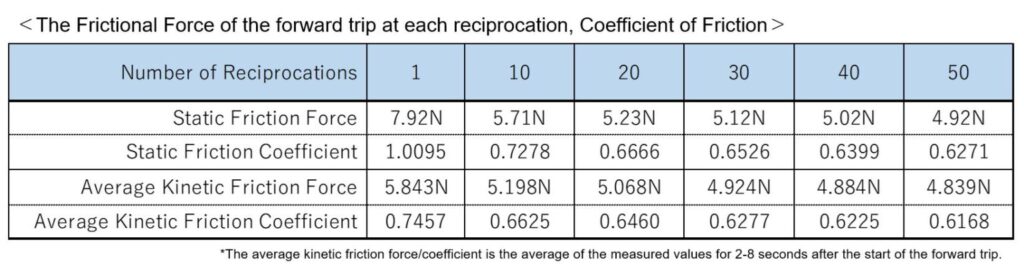

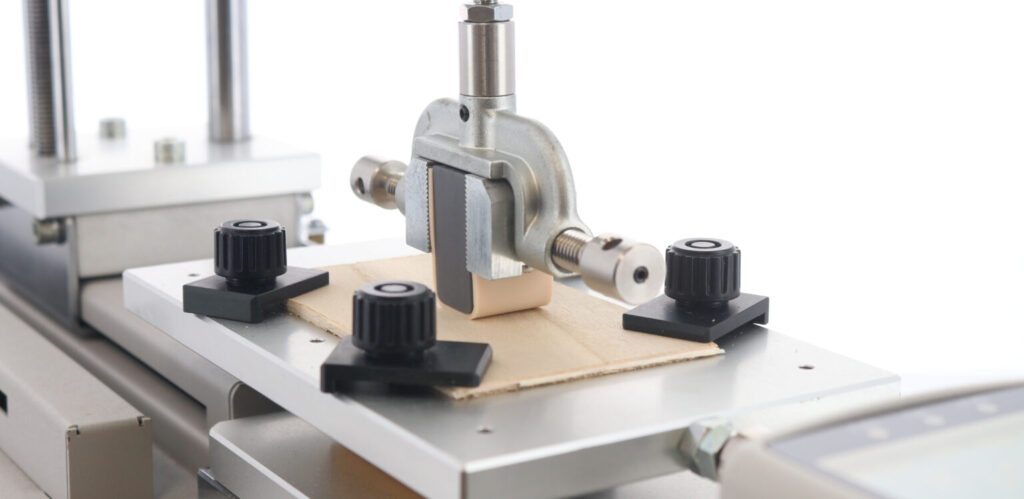

For example, the image shows a wear test for a wood plate and sandpaper. The sandpaper on the wood plate at a constant force moved in repetitive motion (forward and return trips), creating friction on the samples. This test measures the frictional force while making 50 reciprocation movements at approximately 6 cm.

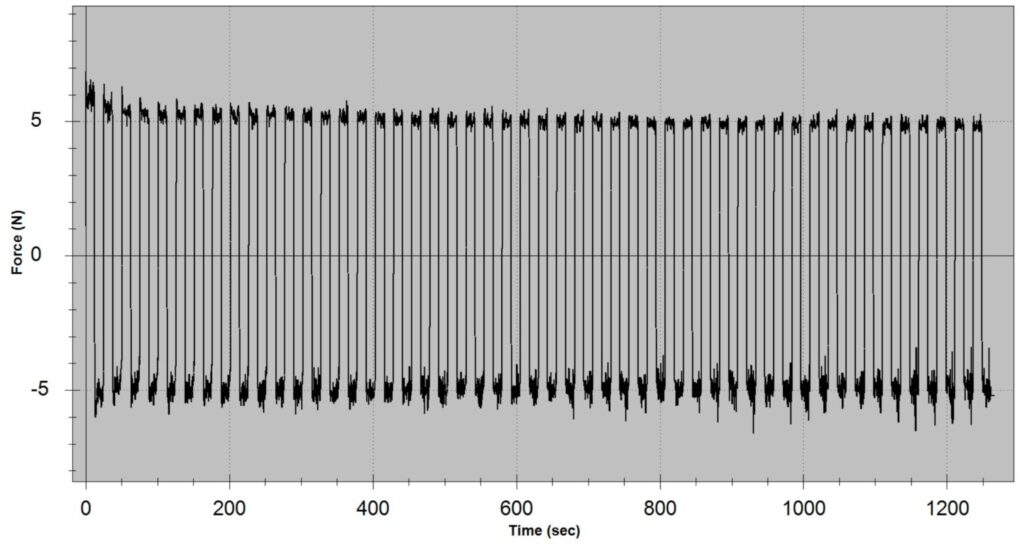

The chart shows the frictional force changes and friction coefficient over 50 reciprocations.

The frictional force measured with the upper attachment with the sample moving to the left as forward trip = positive direction, and the frictional force when moving to the right as reverse/return trip = negative direction measured.

Material wear characteristics analysis such as the following is possible with the friction measurement results.

– Change in the frictional force between the 1st and 50th reciprocations (e.g., The forward trip average kinetic friction force decreased by 1.004N)

– The frictional force transitions up to 50 reciprocations (e.g., Static frictional force decreases significantly within 10 reciprocations, and with the reciprocations increases, the static frictional force amount gradually decreases)

However, from the above wear test data alone, we cannot identify if the decrease in frictional force originated from the wood plate or the sandpaper. It is essential to consider the abrasion on the surfaces of both specimens.

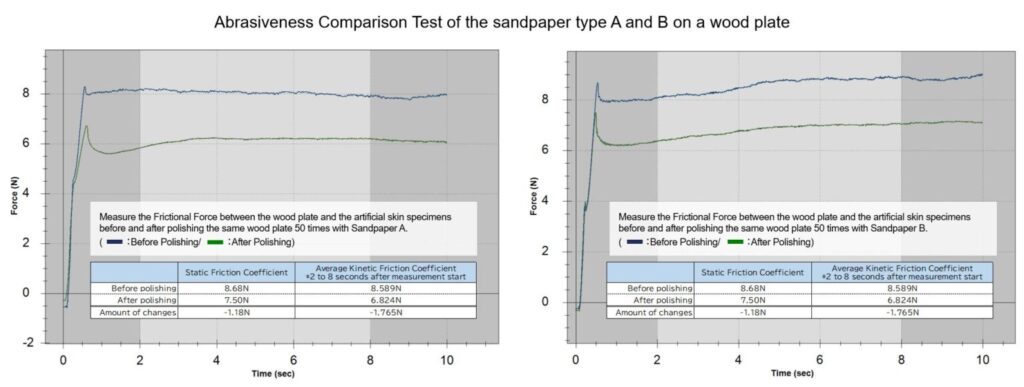

Therefore, when evaluating the abrasiveness of sandpaper on a wood plate, a separate evaluation test needs to be conducted before and after the wear test. For example, the graph below shows the frictional force measurement results on a wood plate using artificial skin before and after the wear test. The frictional force results show a significant reduction from the surface abrasion.

The above measurements (Comparative Test of the Abrasiveness of sandpaper A and B on a wood plate) were conducted using two types of sandpaper: A and B. Each friction force was measured, and the number of changes was calculated. Since the surface of the wood plate is inconsistent with influences such as the wood grain, the frictional force value before polishing is different between the two measurements. Therefore, multiple tests are required for sample comparison and evaluation. By conducting multiple tests and calculating statistical values, it is possible to compare the abrasiveness of sandpaper on wood boards.

The “Wear Test” was introduced to show the sample changes due to Friction, which sums up the last of the “Introduction to Friction Testing” series. We hope these studies have helped with a broader understanding. A range of factors influence the Frictional Force, and the comparisons are essential to align and ensure conditions other than the elements for comparisons.

IMADA’s website introduces a series of video examples on force measurements. In the Force Channel, different force measurement articles with referrable case studies are also introduced for your reference.

*Measurement example videos from here.