Peel test to measure the adhesion strength and weld strength

The Peel Tests: As the words stated, it is the test to measure the forces required to pull and peel off adhesive tapes or the adhesives, which reveals peel (adhesive) strength of the adhesions and ease of peelings to understand the adhesive tape characteristics and functions.

Basically, it is a test for a sticking material peeled for separation from the object stuck to measure the resistance the separation causes. Different test methods depend on the sample, purpose, standard, etc. For example, the methods below are commonly used in the Peel Tests.

- 180 degree peel test

- 90 degree peel test

- 45 degree peel test

- T peel test

- Pull-off test

This time, we will introduce the test methods for the “180 degree peel test” and “90 degree peel test”, which are tests used to measure the peel strength of adhesive tapes and adhesive sheets. 180 degree and 90 degree peel tests are relatively simple test methods among many peel test methods and are adopted by many label manufacturers.

>> Introduction to Peel Tests (2) “45 Degree Peel Test / T Peel Test”

>> Introduction to Peel Tests (3) “Coating Film Peel Test”

180 degree peel test

First, we are introducing the 180 degree peel test method.

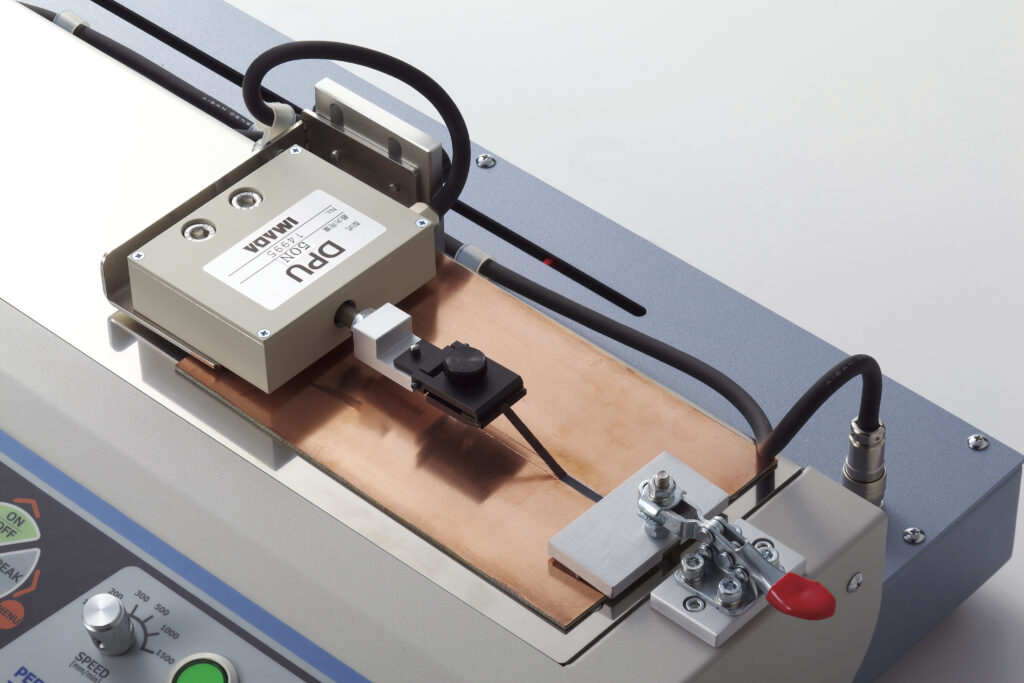

The sample adhesive tape adhered to the 180 degree peel test fixture (Stainless-steel plate) is pulled to peel off at a 180 degree surface attached as stated in the ISO 29862: 2018 Self adhesive tapes – Determination of peel adhesion properties (refer to the image below). By pulling the tape edge upwards, the adhered tape is peeled off from the test fixture, and the peeling force is measured. For the test using horizontal test stand (refer to the image below), the tape edge is pulled and peeled from the base plate at an angle slightly less than 180 degrees.

The 180 degree peel test is simple and popular amongst label manufacturers for their adhesive label product tests. There are also limitations, with the limited stroke length (pull length) or the limited measurable tape thicknesses. The 90 degree peel test application is also applied for the test versatilities as required.

90 degree peel test

In the 90 degree peel test method, the 90 degree peel test fixture (a table jig with a sliding mechanism) is used. The sample tape edge is pulled at a right angle to the adhered surface (refer to the image below), and as the test stand head moves upwards while the adhesive tape being peeled from the fixture surface, the fixture table slides to maintain the peeling angle at 90 degree. Compared to the 180 degree peel test, the 90 degree peel test can cater to a broader range of adhesive sample measurements and testing possible with shorter sample pieces compared with the 180 degree peel test settings.

In the peel test, the tape width also affects the measurement results. Thus the results are generally converted and display the peel force unit: **N/10mm, to remove the effect. The peel force N/10mm can be converted from the measurement result and the sample width [measured value (N) x 10/tape width (mm) = 00N/10mm].

*The 10mm part of the value may vary depending on the standard or other factors.

180 degree peel test and 90 degree peel test comparisons

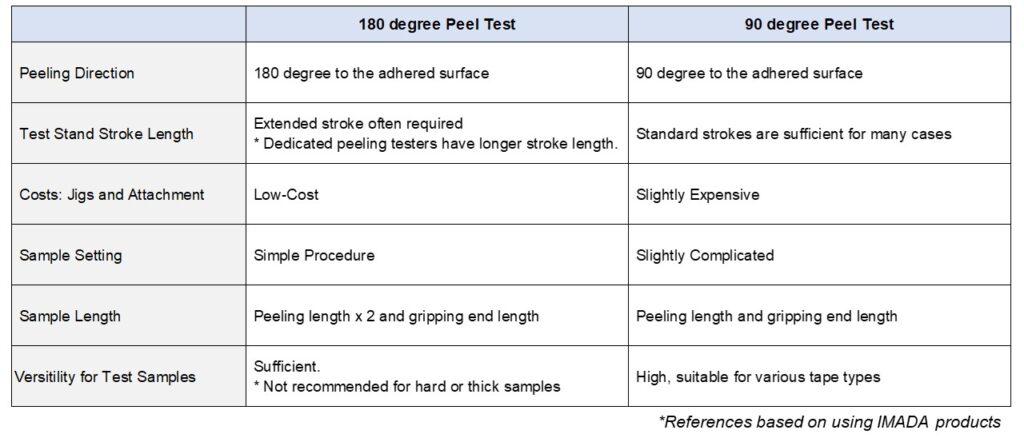

The table below summarizes the characteristics of the 180° and 90° peel tests. For the test method to be adopted, various factors such as (1) sample, (2) standard, (3) peeling method in the actual using environment, and (4) company/industry rules and regulations as such, must be carefully evaluated. In the case of quality assurance confirmation to customers, etc., prior confirmation of the suppliers’ requirements and standards is essential.

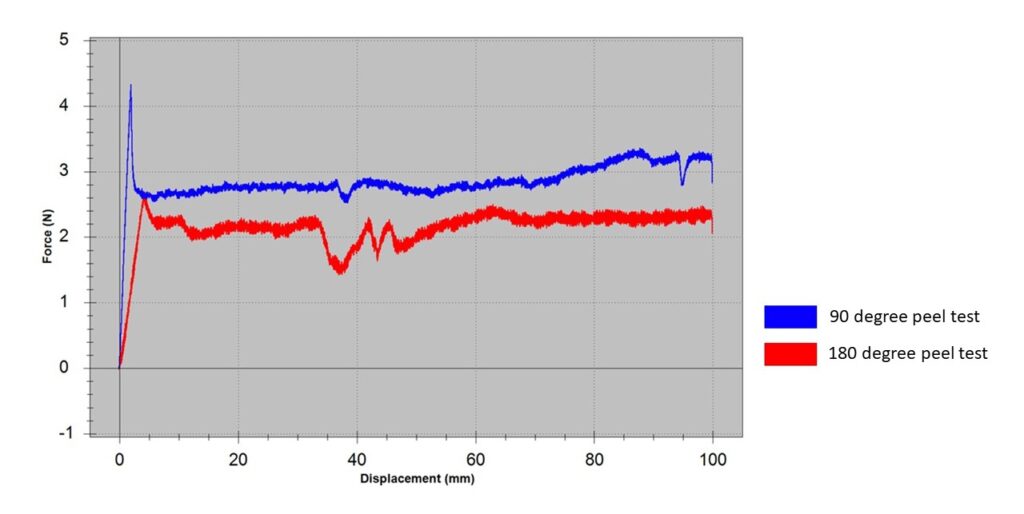

For the peel strength comparison, the test methods’ consistency is fundamental. The graph below shows the results of the same adhesive tape measurements using two testing methods, and the significant differences in the values are indicated.

The average peel strength, according to ISO 29862: 2018, is 1.11 N/10 mm in the 180 degree peel test and 1.46 N/10 mm in the 90 degree peel test, a difference of more than 1.3 times. In addition, in the 90 degree peel test, the graph shows that a more significant resistance is generated at the beginning of peeling.

The above graph is just an example, and in actual tests, depending on the characteristics of the sample, the measured value of the 180 degree peel test may exceed the measured value of the 90 degree peel test.

Standardizing the test methods is essential for the comparison and quality control requirements.

Summary

In this article, we have introduced two types of peel tests for adhesive tapes and sheets, performed with different angles; there are also other types of peel tests for different purposes, samples and methods.

We also introduce the 45 degree and the T peel tests in the next series.

We aim to introduce various articles on Forces and practical Force measurements through Force-Channel. Please also check other articles and let us know if any other topics are of your interest.