Q: We have decided to use spout pouches as packaging containers for a new product. This is our first time using spout pouches. What kinds of quality control tests should we conduct?

A: For tests used force measurement, cap torque tests, compression tests, seal strength tests, and puncture resistance tests are commonly performed. Other tests such as drop tests and residual solvent tests are also conducted for spout pouch quality evaluation. This article introduces four tests that utilize force measurement: Cap Torque Test, Compression Test, Seal Strength Test, and Puncture Resistance Test.

| Cap Torque Test | Compression Test | Seal Strength Test | Puncture Resistance Test |

|---|---|---|---|

|  |  |  |

Cap Torque Test

The cap torque test measures the torque (rotational force) required to open a screw cap. It is essential to ensure that the cap does not unintentionally loosen during transport and storage, and from the perspective of user-friendliness, the required opening torque is also an important parameter.

A torque gauge is used for measurement, but spout pouches present a challenge because the pouch section is soft and easily deforms. Therefore, a special fixture that holds only the spout portion is required.

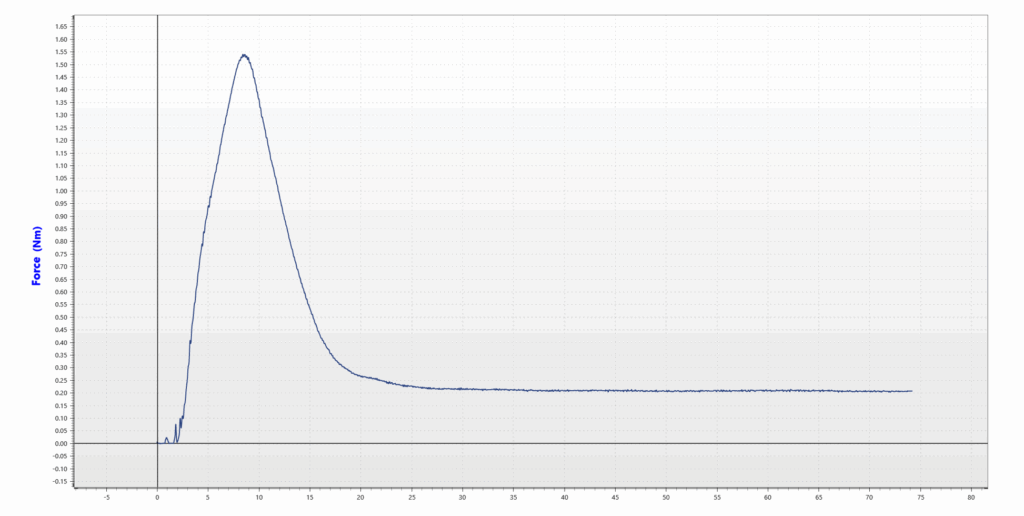

In screw cap opening torque measurements, the torque curve typically follows the pattern shown in the graph below. Therefore, the peak value is often managed as a key parameter. Companies check whether the peak value is within predefined limits.

For improved accuracy and reproducibility, a motorized test stand capable of rotating at a constant speed is recommended.

>> Click here for the video for Spout Pouch Cap Opening Torque Test

Compression Test & Seal Strength Test

Both compression test and seal strength test evaluate the strength of the sealing area against applied force. Because the primary function of packaging is to protect its contents, proper management of seal strength is crucial. These tests are conducted using force measurement instruments such as force gauges.

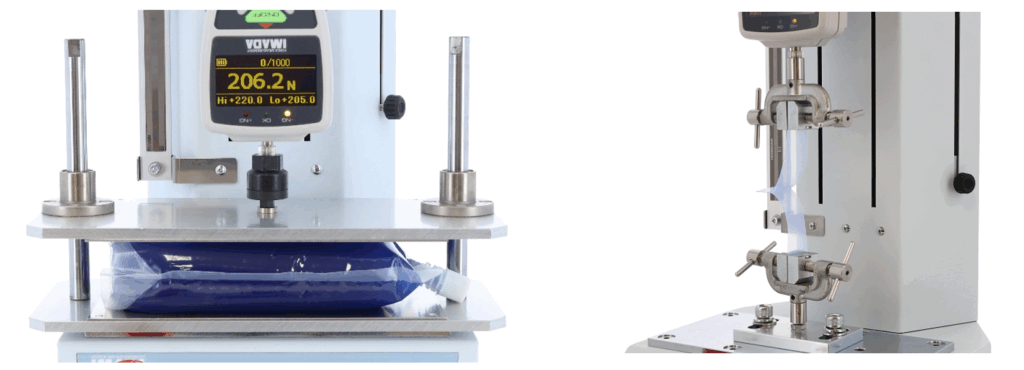

Compression Test

In compression tests, the entire spout pouch is compressed with a specified load for a specified period. The test checks for leakage of contents or damage to the pouch. Testing conditions often follow standards such as JIS Z 0238:1998. JIS Z 0238 defines force values applied based on the volume of the contents.

Seal Strength Test

In seal strength tests, a section of the sealed area is cut to a predetermined width, and its tensile strength is measured. This is known as the T-peel test, a common evaluation method for heat-sealed packaging. For reference, JIS Z 0238 specifies details such as sample width (15 mm) and recommended seal strength values based on packaging application.

>> Click here for the video for Pouch Compression Test

>> Click here for the video for Seal Strength Test

Puncture Resistance Test

Puncture resistance tests evaluate the strength of the film used in spout pouches. A thin pin is pressed into the film, and the force value at penetration is measured. Low puncture resistance may lead to damage during consumer handling, such as in bags or backpacks. Standards include JIS Z 1707:2019, which specifies pin shape and test speeds.

>> Click here for the video for Puncture Resistance Test

Summary

This article introduced several quality control tests commonly conducted for spout pouches. Spout pouch quality evaluation includes additional tests other than force measurement. When selecting appropriate tests, consider industry standards and in-house criteria. IMADA also assists in selecting force measurement instruments for your force measurement requirements. Please do not hesitate to contact us from our Product and Service Site.