Many types of gripping fixtures have been introduced, especially for Tensile Testing. Choosing the most suitable Grips requires understanding the various factors and considerations for assessments and how to proceed with the selection effectively.

This article explains the points to consider when choosing the best Grip fixtures.

The criteria for consideration: –

- Select a grip fixture considering “the sample dimension”, “the estimated force value of the measurement”, and “the specimen materials and the properties”.

- Check “the max. sample thickness”, “jaw width”, “capacity”, “structure”, and “jaw face types” of grip fixtures.

Choose from the Measuring Specimen Dimensions

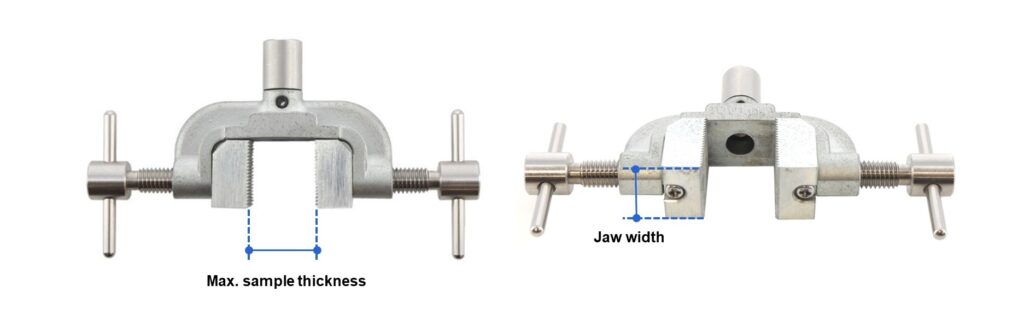

Before selecting a grip fixture, check the sample’s dimensions: the max. sample thickness of the grip fixture must be more than the sample thickness. *1

Selecting the suitable grips for the specimen and taking jaw widths are essential. If the jaw width is shorter relative to the width of the specimen, uneven forces may be applied, and the result would be inaccurate. Unless specific setting standards are required, choose a grip with jaw widths sufficient to cover the width of the specimen to be measured.

There should be no significant problems even if the gripping jaw widths are larger relative to the measuring specimens. However, the jaw widths outside the general tolerance standard may become a hindrance depending on the measurement content. For example, pulling one bristle from a toothbrush using a sizeable gripping surface may make the correct centering and position settings difficult.

- Choose a grip with the grip jaw having the maximum sample thickness wider than the thickness of the measuring specimen.

- Choose a grip with a jaw that has the jaw width wider than the width of the specimen.

- The jaw widths must be carefully selected to avoid possible hindrances depending on the type of measurement used.v

*1 Please refer to the specifications for the individual Grips and fixtures for details and other options.

Choose from the Required Measurement Forces

The magnitude of the force for measurement and the grip’s maximum measurable force values must be considered.

Do not attempt to measure forces larger than the capacity*2 of each grip fixtures. (Refer to the individual specifications). It is essential to prevent overloading, as it could cause irrevocable damage to the fixtures, causing them to break and malfunction from large instantaneous generated forces, especially with breaking tests. Always remember to use the grips with appropriate force capacity in relation to the measurement requirements.

Also, as per the above examples,the grips’ weight, if too heavy for the force capacity of the force gauge, would cause strain on the measuring shaft. IMADA recommends that the weight of the grips should be no more than 10% of the capacity of the force gauge.

- Select a grip whose capacity is larger than the expected force value.

- Select a grip whose weight is within 10% of the force gauge capacity.

*2 The capacity means the maximum measurable force of the measuring instrument. Overloading would result in not only irrevocable damage to the fixture but also the damage to the sensor.

Choose from the Materials and the Properties of the Specimens

So far, we have made introductions on how best to narrow down the Gripping Fixture options to meet the basic measurement requirements. Lastly, consider the property of the sample specimen.

Examples of Specimens

- Thin and Soft, easily deformed (soft metal pieces, rubber sheets, etc.)

- Hard / Glossy / Polished / Slippery surfaces (stainless steel, etc.)

- Fragile / Tearly from the Jaw gripping pressure (cellophane, aluminum foil, etc.)

[Thin and Soft, Easily Deformed]

The structures of the grip fixtures with Wedge / Pantograph / Cam are suitable for gripping soft specimens elongating with the thickness decrease with the force applications. These grips automatically increase the gripping strength with the force application during the measurement. Therefore, the gripping force at the start is weaker, which means they are unsuitable for gripping hard and slippery surface specimens.

[Stiff / Rigid / Slippery]

For gripping Stiff / Rigid specimens, such as stainless steel, use the grip with Screw-type jaw, which helps to provide additional tightening adjustment for the claws to firmly bite into the surface for firm grip to prevent the specimen from slipping off. Also, if the sample is thin and stiff, a screw-type jaw with a urethane surface claw on one side helps provide a firm, stable grip.

[Fragile / Tearly]

Specimens with Fragile and Tearly natures, such as cellophane, tend to tear and break when gripped with claw surfaces with a V-Notch finish. *3 Grips with flat claw surfaces or urethane surfaces are recommended for specimens in this category. In addition, the knurled teeth help to reduce the risk of splintering and have a non-slip, firm grip effect.

- For thin and soft, easily deformed specimens, choose self-tightening structure grips.

- For stiff / rigid / slippery surface specimens, choose grips with screw-type jaw.

- For fragile / tearly specimens, choose grips with plain jaw faces or the urethane surfaces.

*3 When sample specimens get torn or broken from using unsuitable grip jaw faces and their characteristics, it will lead to the deformation of the sample specimen, incorrect measurement, and inaccurate results.

Refer to examples and case studies for measurements

Are you clear on how we recommend the Grips and Fixture selections for your measurement needs? The following are some of the Grip options available for you to base the selections, taking the pointers recommended for the possible options.

- Choose from the specimen dimensions

- Choose from the amount of force required

- Choose from the specimen materials and the properties

Please also refer to some of the measurement solution with additional fixtures to support with the various measurements. Depending on the specimens to be measured, dedicated jigs may be available as shown in the image below.

IMADA publishes introductory measurement examples and solution videos using various tensile testing grips with supporting jigs and fixtures on the website; for additional hints, please visit the link below: –

Measurement Example Videos on Tensile Tests (Imada Co., Ltd. product/service site) >

Supplement: Tension Tests Grip examples*4

|  |  | |

| Product | Film Grip | Flat Chuck | Fine Point Chuck |

| Max. Sample Thickness | 0.2-2mm | 10-30mm | 0.5mm |

| Jaw Width | 20-40mm | 20-29mm | 1mm |

| Capacity | 250-500N | 1000-5000N | 50-100N |

| Note | Designed to grip film, paper, and other thin materials. Various models available to fit your testing samples. | Ideal for a variety of tension tests of thin to thick samples. Replaceable claws are available for some products. | Ideal for tension testing of fine samples such as fiber and hair where space is limited |

|  |  | |

| Product | Pantograph Grip | Wedge Grip | Cam Grip |

| Max. Sample Thickness | 6-10mm*5 | 2-8mm | 2-4mm |

| Jaw Width | 5-30mm | 9.8-23.8mm | Roller width: 30-50mm |

| Capacity | 500-2500N | 500-5000N | 500-2000N |

| Note | A self-tightening structure grip. Designed to grip sample very easily. | A self-tightening structure grip. The lever system allows grip the sample relatively firmly from the beginning. | A self-tightening structure grip. Ideal for gripping thin and rectangle shaped sample. |

|  |  | |

| Product | Pin Grip | Flat Chuck | Fine Point Chuck |

| Max. Sample Thickness | Max. sample diameter: φ3.2mm | Max. sample diameter: φ13mm*6 | 35-66mm |

| Jaw Width | ― | ― | 38-62mm |

| Capacity | 150N | 1000-5000N | 250-2000N |

| Note | Ideal for gripping thin wired- shaped sample. Designed to be used for both compression and tension testing. | Ideal for gripping round cylindrical shaped sample. Designed to prevent the samples from slipping. | A grip for tension tests designed to mount to vertical test stands. Screw-type for firm gripping. |

*4 Excerpt from products handled by IMADA CO., LTD. (as of March 2024)

*5 Opening width: 15-20mm.

*6 Min. sample diameter: φ0.5-2.0mm.