A force gauge is a measuring instrument used to measure forces (loads) such as compressive and tensile forces. It is widely used primarily in the manufacturing industry, supporting quality control, research, and product development. It is essential that the performance of the force gauge is accurate and display the correct results.

Although the instrument precision itself is a valuable factor, if the best procedures are incorrectly followed, the measurement results from the force gauge would be inaccurate. This article introduces preliminary points to bear in mind for increasing accuracy in measurement results.

In this article, we introduce how force gauge should be used for accurate measurements.

Forces Applied to the Measuring Shaft at a Right Angle and Vertically

The force must be applied in the axial direction of the shaft when measuring forces. The correct measurement result will not be obtained with incorrect force application to the measuring shaft. Basically, the force gauge is designed to display accurate values when the force is applied in the axial direction. Additionally, caution must be taken not to apply excess forces to the measuring shaft in bending or rotational directions to avoid malfunction and breakage.

Zero Reset Procedure

Zero Reset (zero adjustment) to clear the value displayed to Zero. By setting a reference point at the start of measurement, the force value applied on the sample is displayed, removing weights of attachments. However, it is important to note that depending on the timing of the zero reset, errors may influence the measurement results. Though the zero reset timing depends on the measurement contents, generally it is performed at the following times.

- Perform a zero reset at the measuring position after attachments installment

- No Zero reset performed after sample instalment (When attaching a sample to the force gauge shaft for a compression test, perform a zero reset after attaching the sample.)

It is essential to clarify the pre-measurement procedures, including Zero Resetting, to maintain data consistency. Clarifying the procedures clearly also reduces the measurement result variations between the operators.

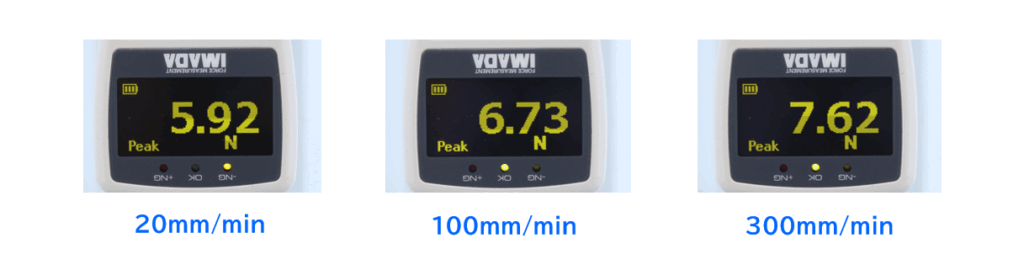

Uniform Test Speed

The test speed (has a significant effect on the force measurement results. Even when the strength of the same sample is measured, the measurement results will not be even if the measurement speed is uneven. Using a motorized test stand can provide uniform test speeds, but even without, setting guidelines such as “press at a rate of 20 N in 1 second” is effective for adjusting the test speed.

Regular Accuracy Checks and Calibrations

Force values displayed on force gauges may change over time, depending on the environment and frequency of use. Also, if a force gauge has experienced an overload from overcapacity load application, it may malfunction and produce inaccurate measurement results. So, in addition to periodical calibration and adjustment, it is essential to perform daily accuracy checks to identify any issues or problems to meet your requirements.

Summary

In order to increase the measurement accuracy, we explained how to correctly use the force gauge for your measurements. This article has been written on the assumption that you already have the force gauges, but the selection of measurement instruments, including force gauges, is also important for accurate measurements. IMADA also assists in selecting force measurement instruments for your force measurement requirements. Please do not hesitate to contact us from our Product and Service Site.