As a part of IMADA’s social contribution project, we offer to sponsor the lending of measuring instruments to local schools to support and encourage students interested in their research projects. We have received an exciting project report on their Experiment Challenge from the students from Komatsu High School, which we wish to share on this occasion.

I need a re-stickable glue!

“Oh Nooooo! I ruined my notebook! I did not mean to paste the print here‥‥ sigh!!!! Why there aren’t any adhesives that could easily be un-pasted without damaging the notebook page.”

The experience made the Komatsu high school students decide on this experiment that they would make glue with high durability and the ability to be removed afterwards. The glue material they focused on was starch. When the water-added starch is heated, it undergoes alpha-formation, in which the molecules become irregularly aligned and, as a result, soften into a gelatinized paste, and beta-formation, in which the moisture is subsequently evaporated, and the starch hardens. As a first step, they looked for a way to check the durability of their glue which is described as peeling forces, and came across IMADA.

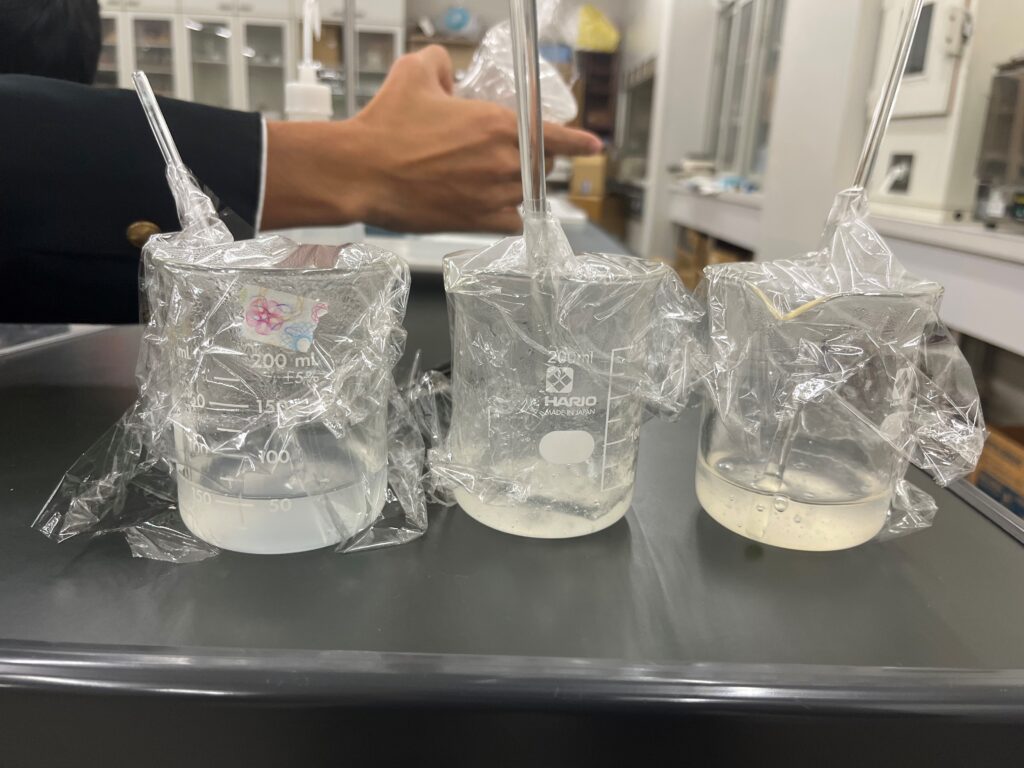

Photo: Handmade starch glues with different starch concentration

Would it stick stronger from higher starch concentration?

Based on the hypothesis that the starch glue would gain more power with the higher starch mass percent concentration, the students used potatoes to make their starch. The water-mixed potato starch was heated until it turned transparent, and the starch concentration ratios were set at 3 / 6 / 9 / 12 / 13 / 14 / 15 and 18%.

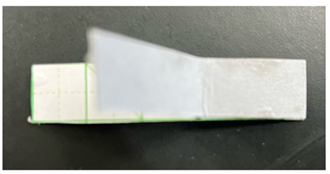

Testing sample specimens were prepared by pasting the two pieces of the graph grid sheet together with the homemade glue. The graph grid paper was cut into five square strips each and folded at 90-degrees along the lines. Apply a thin layer of the starch glue to the two squares out of the five and placed between the two acrylic plates to apply pressure with weight for 5 minutes, then left to dry in a well-ventilated environment for a day. (It is inspiring that they made every effort to obtain stable conditions for their measurement accuracy!)

Photo: Handmade Measurement Sample

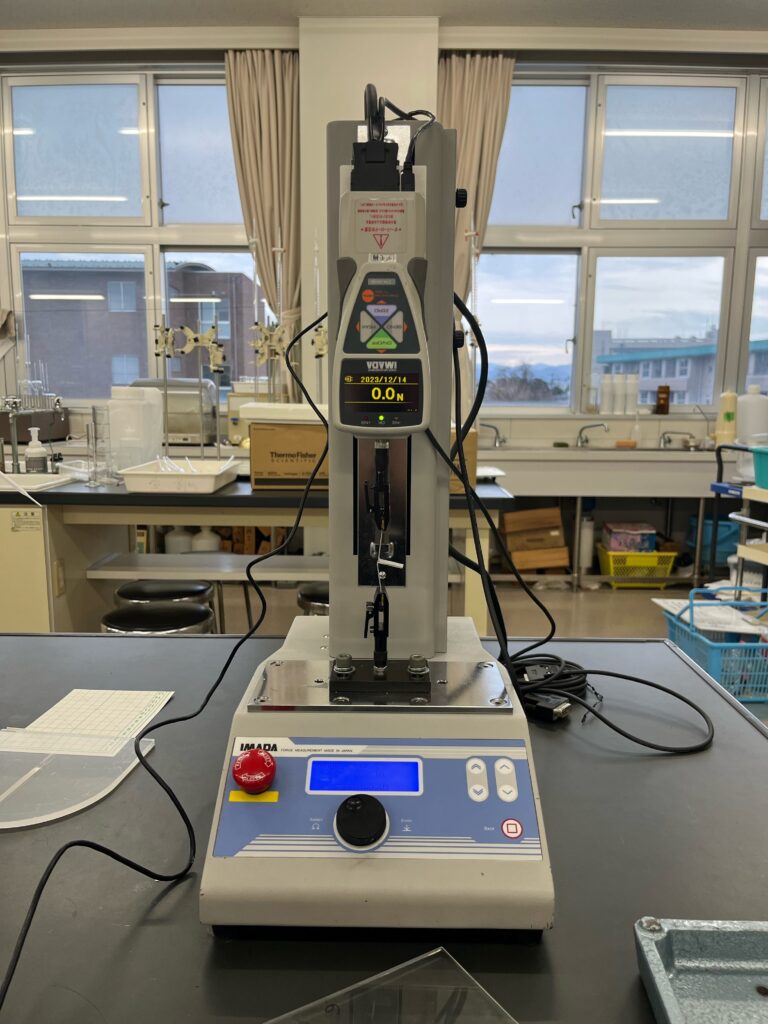

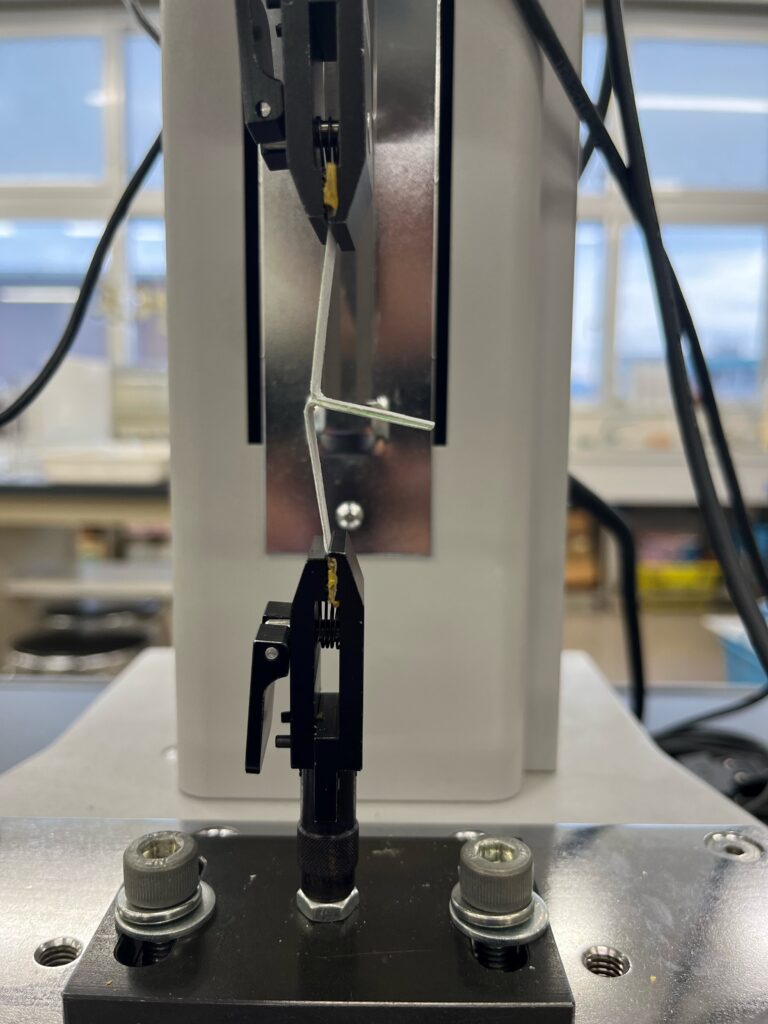

Once the samples were ready, they began the experiments with the motorized test stand and the force gauge IMADA lent. We recommended using film chucks to grip and pull to separate the pasted sample pieces vertically.

Using the T-peel Test method, the peeling forces were measured until the starch glue pasted section of the grid paper strap (sample) was separated with the vertical pulling force.

They previously tried manually measuring peeling force using a spring scale but could not obtain a stable pulling speed. So we advised them to set up the consistent measurement speed for the test stand.

Photo: During the measurement

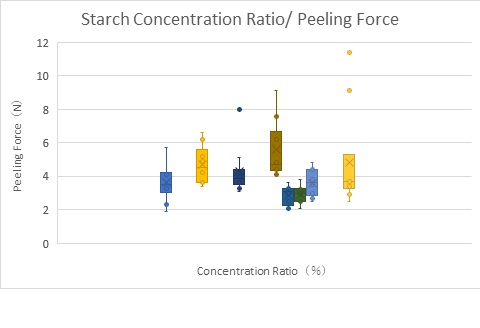

Considering the differences between the individual samples, each was measured 10 times per different starch concentration. The mean values were made into a boxplot, and the median values were compared.

Box plots

The Viscosity and Penetration Rate are the KEY!

Contrary to prior expectations that more forces would be measured with glues from higher starch concentration, the starch glue with a 12% concentration showed the highest mean and median values and the strongest peeling force. The peeling force decreased rapidly from 12% to 13%; no increase was identified even with the 18%. Based on these results, the students focused on the glue viscosity and penetration rate. Preliminary experiments have shown that viscosity increases rapidly as starch concentration increases and previous research has demonstrated that increased viscosity decreases permeability.

It was concluded that the result was due to the increase in viscosity, which made the glue penetration to the graph paper difficult. The paper could not take the glue in.

Although not shown in the above table, they also tested with the (they measured) peeling force of the similar commercially sold glue using the same method. The average peeling force of the homemade starch glue of 12% concentration showed the highest peeling force at 5.58N. In contrast, the comparison target, the average peeling force of the similar commercially sold Glue, was 3.05N. Therefore, it is evident that they succeeded in homemaking the prototype of a starch glue, which was more durable than commercially sold glue. Congratulations to the Komatsu High School Project Team!

We understood that they have had several experiences with various measurements and the operation procedures were very well organized from the moment we met. In fact, they quicky adopted with using IMADA measuring devices.

We were thrilled to read the reports with exciting results, and very happy to have found that the students were satisfied with the results and the experiences they achieved from IMADA. Thank you very much to the project team members of Komatsu High School for their challenge and the report!

If any students are interested in experimenting with Force Measuring devices for your projects and research, don’t hesitate to contact us from here. IMADA may be able to support your “???” with the scientific approaches to problem-solving.