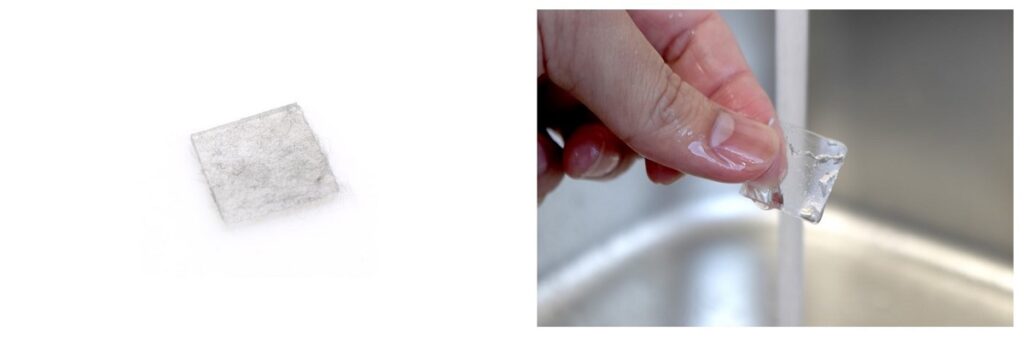

Double-sided nano tapes are very popular in Japan for their strong adhesiveness but with easy washability and reusable ability*.

So, how much of the adhesive force would it regain? as the product description? In this article, we have introduced the results of our investigation based on the Force measurements.

[Summery of this article]

- Comparison for the Adhesiveness with “tack” and “shear” tests with New and Re-use tape samples

- 70-90% of the adhesive strength was re-stored from the re-use, washed sample, removing adhered deposits from the adhesive surface with water using hand.

*Do not use hot water or detergent unless stated in the product description.

>> Introduction to Peel Tests: 180 Degree Peel Test / 90 Degree Peel Test

Measure the adhesive strength: Tack and Shear Tests

First, the adhesive strength of 2 tape types (Nano and Paper Tapes) in new conditions was measured by Tack and Shear Test methods to obtain the fundamental adhesive strength reference values.

- Tack Test: Apply perpendicular force to the adhesive surface.

- Shear Test: Apply horizontal force to the adhesive surface.

[Procedures of Tack Tests]

1. 20cm x 20cm double-sided adhesive tape pasted to the test stand table

2. Press the tape with the force gauge by approx. 20N for 5 seconds from above

3. Lift the force gauge up and check the required force when the adhesive tape is peeled off from the force gauge or the table

[Procedures of Shear Tests]

1. Insert 20cm x 20cm double-sided adhesive tape between the two resin plates

2. Place 20N weight to press and adhere for 10 seconds from above

3. Remove the weight and set plates to the test Stand (refer to the image below)

4. The plates are pulled apart up and down, and adhesion resistances are measured

-1024x500.jpg)

This time, measurements were performed with three different samples (nano tape with hard/weak adhesion and paper tape). The measurement results are shown in the table below.

| Nano tape (Hard adhesion) | Nano tape (Weak adhesion) | Paper tape | |

|---|---|---|---|

| Tack Test | 69.9N | 47.1N | 9.1N |

| Shear Test | 36.7N | 65.1N | 72.2N |

Tack Test: The nano tape samples used have superior adhesive strength compared to the paper tape sample. For example, gel tape would be useful in applications such as attaching a box upside down.

Shear Test: The paper tape sample shows superior adhesive strength. However, the difference is minor.

It helps to understand the characteristics of the different types for different purposes.

Adhesive Strength Recovery Comparison Test: The Clothing Fiber

Following the new tape adhesion strength test, we have checked the adhesive strength recovery of the Re-Use tape with Tack and Shear tests. The first step was to verify whether the adhesion of the tape which the fabric fibers are stuck can be recovered by washing away. (In this case, the verification was conducted with polyester felt fabric, and running lukewarm water was used to wash)

[Procedures]

- Stick the tape sample to the felt fabric sample to adhere the fibers to the tape surface.

- Check that the adhering strength of the tape has dramatically reduced with your finger.

- Wash the nano tape under lukewarm running water and rub to remove the fiber adhered to the adhesive surfaces.

- Shake the water off, dry naturally, and repeat the measurement of the adhesive strength as in the above #1 procedures.

- Compare the re-use tape adhesive strength retention rate relative to the adhesive strength in the new condition.

The entire process wasrepeated twice using the same tape sample to verify the adherence recovery resiliency during repeated use.

[Hard Adhesion Nano Tape Re-Use Test Results]

| Tack Test | Shear Test | |

|---|---|---|

| New Tape Sample (Standard Value) | 69.9N | 36.7N |

| 1st wash with water | 60.0N (85.8%) | 30.9N (84.2%) |

| 2nd wash with water | 59.2N (84.7%) | 31.8N (86.6%) |

[Weak Adhesion Nano Tape Re-Use Test Results]

| Tack Test | Shear Test | |

|---|---|---|

| New Tape Sample (Standard Value) | 47.1N | 65.1N |

| 1st wash with water | 39.8N (84.5%) | 59.1N (90.8%) |

| 2nd wash with water | 42.7N (90.7%) | 60.6N (93.0%) |

From the result, up to around 85-90% of the new condition of the tape adhesion strength is restored. Considering that dust floating in the air adheres during drying, the number has recovered to a very high level by simply removing the surface fiber.

However, when the measurements were conducted without drying the adhesive surfaces thoroughly, the adhesive level was not maintained to an acceptable level. Drying the tape surface is necessary to restore the adhering strength.

Adhesive Strength Recovery Comparison Test: The Cooking Oil

We have also conducted additional tests using cooking oil application to the adhesive surface, which, in most cases, is considered one of the significant factors in reducing adhesive strength. We have applied Cooking Oil for this test.

[Procedures]

- Pour cooking oil to cover the entire adhesive surface of the nano tape sample surfaces

- Check that the oil-coated surface has lost the adhering strength with your finger

- Wash away the oil on the nano tape surface under lukewarm running water

- Shake the water off, dry naturally, and repeat the measurement of the adhesive strength as in the above #1 procedures

- Compare the re-use tape adhesive strength retention rate relative to the adhesive strength in the new condition

Similar to the above #2, cooking oil was applied to the nano tape samples and tested for adhesion recovery after repeated use by repeating twice the wash to remove the oil under running water and measuring.

[Hard Adhesion Nano Tape Re-Use Test Results]

| Tack Test | Shear Test | |

|---|---|---|

| New Tape Sample (Standard Value) | 69.9N | 36.7N |

| 1st wash with water | 54.7N (78.3%) | 26.6N (72.5%) |

| 2nd wash with water | 54.2N (77.5%) | 25.4N (69.2%) |

[Weak Adhesion Nano Tape Re-Use Test Results]

| Tack Test | Shear Test | |

|---|---|---|

| New Tape Sample (Standard Value) | 47.1N | 65.1N |

| 1st wash with water | 33.9N (71.2%) | 55.2N (84.8%) |

| 2nd wash with water | 35.8N (76.0%) | 52.3N (80.3%) |

As a result of measurements, the adhesive strength was restored up to about 70-80% of its new original state. The lower recovery performance compared to removing fiber under running water may be due to the lower affinity between water and oil. However, the adhesive strength is still recovered and may serve as double-sided adhesive tape at an acceptable level. Depending on the intended use, it may be possible to repeat the procedure to maintain a sufficient level of adherence to continue the use.

*For additional information, we used dishwashing detergent to dissolve the cooking oil from the sample we used and rinsed thoroughly under running water; the adhesive strength had recovered to about 90%. However, this may not apply to some products, and use of the detergents may not be recommended. Please refer to the product information for further details before use.

Summary – The Nano-Tape Adhesive Strength Measurement Results

The following conclusions were met.

- When the force is applied to the nano tape adhesive surface in a vertical direction from the adhesive surface, the nano tape exhibits a solid adhesive force

- The adhesive strength of the nano tape in the horizontal direction (sliding direction) to the adhesive surface is less than that of double-sided paper adhesive tapes

- When fabric fiber or oil is attached to the adhesive surface, the adherence force is decreased or lost but restored up to around 70-90% when washed under running water to remove them from the surface

Although the measurement results are for references only and may not apply to other similar products.

IMADA’s website has many video examples of measurements and solution hints related to the adhesive and peel strength tests. Furthermore, please also check Force Channel for related tests and other articles for your reference.