IMADA began in 1947 when it made the first mechanical force gauge in Japan at the request of an aviation industry manufacturer to develop a force measurement tool that was difficult to obtain at the time. Since then, we have supported quality control sites in various industries such as automobiles, electronic parts, and cosmetics, and have contributed to domestic and overseas manufacturing. Even now, our mechanical force gauges are used not only for quality control measurement of aircrafts, but also for daily inspection of fire shutters at buildings, and have established a reputation for their quality.

However, the technology and parts used for our mechanical force gauges have, surprisingly, not changed significantly since the company was founded.

Here, we will introduce various IMADA’s initiatives that win the trust of the market for mechanical force gauges we have cultivated since our founding.

Each spring of the same model is fine-tuned depending on its uniqueness

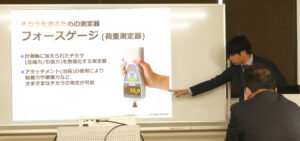

As measurement devices, mechanical force gauges are expected to show accurate measuring results. The manufacturing process of IMADA’s mechanical force gauges includes various activities to ensure the device’s accuracy.

For example, a spring is one of the important parts that greatly affects the measurement results. Even if the springs are of the same type and application, each one has its own uniqueness, so at IMADA, we manually perform additional machining to adjust its function according to each uniqueness. The diameter of the hole where the spring is inserted is also finely adjusted depending on the shape of the spring to tighten the spring into the parts better. The spring that increases measuring accuracy in this way is then combined with a solid coiling spring that can show more stable changes around its free length when force is applied. This structure allows our mechanical force gauges to keep its measuring accuracy.

Such adjustment work is conducted several times during the entire assembling process of mechanical force gauges and at each adjustment, quality check is implemented. Therefore we can ensure the high quality for our mechanical force gauges.

Aside from springs, dial gauges which indicate the measuring results are required high standard of slidability. Thus, the sliding surface roughness is appropriately adjusted so that the needle can be advanced with the minimum resistance and can stop with frictional resistance.

So as these examples show, we have provided mechanical force gauges with high precision by setting high standards for each part.

Even a force gauge made 40 years ago may be fixed?

Sometimes we receive repairing requests of mechanical force gauges used for 30 to 40 years. You may wonder whether the devices are able to be fixed. But rest assured. Some parts of mechanical force gauges have been used since the very first model (though some minor adjustment is applied.) and our factory keeps old maintenance parts and compatible parts as well.

IMADA’s mechanical force gauges have high durability to be used for long time under appropriate circumstance. In addition, our various customer supports such as the said repairment service and calibration accredited by ISO17025 realize expansion of our product lifetime.

Regarding calibration, IMADA recommends product users to do calibration once a year. Our calibration is offered by our calibration specialists who pass IMADA and ISO calibration examination and is implemented in the shock absorbing room where the temperature and humidity are managed.

Pursuing high quality and usability

The precision and durability of IMADA’s mechanical force gauges promise high reproducibility in measurements to product users. Also, there are other mechanisms to improve the device’s usability.

Our force gauge’s slide bearing, that defines the direction in which force is applied during measurement, is designed to move back and forth instead of sideways. This makes it possible to correct the amount of force applied during measurement so that the force gauge can obtain more accurate results.

The aluminum die-cast body of the device has proper robustness and lightness for the force measurement environment and is designed with ease of grip.

Our mechanical force gauge has many elements that have been preserved since our founding, such as the parts and technology, but only the appearance has been changed several times according to the voices of customers and the innovations of processing technology.

In order to provide the optimum user experience to support the better manufacturing of our customers, we have been carefully elaborating the mechanical force gauge. It may be said the history of updating this device embodies IMADA’s mission to pursue the world-class quality and customer satisfaction.