Heat seal bags are commonly used for food packaging. Have you ever noticed that heat seal bags often have notches along with words like “tear notch” or “open here”? This article presents the results of research on the effects of notches on ease of opening based on the force measurement.

Measurement Methods and Conditions

Measurements were performed under the following conditions with reference to JIS S 0021-2 (2018) *1.

- The samples are two pieces of film with one side heat-sealed.

- Fix the heat-sealed part with two grip fixtures. (hold the film with a 3mm gap)

- One grip is connected to the force gauge*2 with a string, while the other is fixed to the table.

- Measure the force required to tear by moving up the force gauge at a speed of 600 mm/min.

*1 The measurements are conducted under Force Channel’s own conditions which don’t comply with JIS S 0021-2 (2018)

*2 Force gauges are used to measure the force value. The measurement results are displayed in units of Newtons (N).

Measurement Results

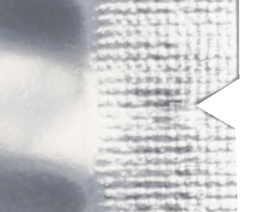

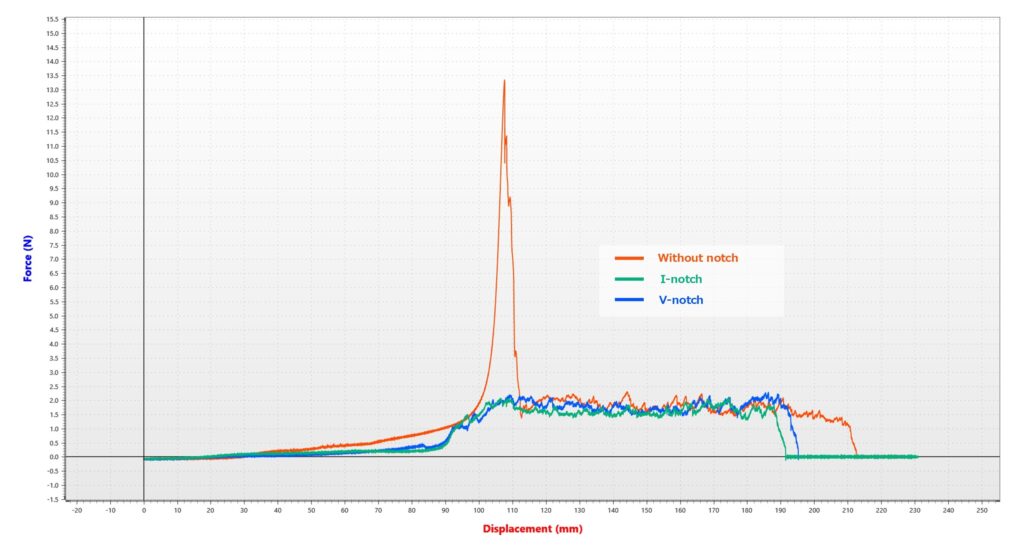

We used the same heat seal bag to create samples with (1) without notch, (2) with a notch(I-notch), and (3) with a notch(V-notch), and conducted measurements for this experiment. The results of the measurements are shown in the table and graph below.

| Sample (1): without notch | Sample (2): I-notch | Sample (3): V-notch |

|  |  |

| Maximum force value (Opening force): 13.34N | Maximum force value (Opening force): 2.10N | Maximum force value (Opening force): 2.29N |

The measurement results indicate that the presence of a notch requires less force to open the bag. On the other hand, there seems to be no significant difference in openability between the I-notch and V-notch.

In this measurement, the sample was firmly gripped with fixtures, so it could be opened even without a notch. However, in reality, it is not easy to open it with human fingers. (When I tried measuring with my fingers, slippage occurred between my fingers and the film at around 10N of force, making it impossible to open.)

The notch enables easier opening because of a phenomenon known as stress concentration. The force applied to a sample is concentrated at points where there are large changes in shape, such as corners and incision (stress concentration). For a sample with a notch, the force concentrates at the notch, allowing it to be opened with less force.

In addition, for a sample without notch, stress concentration occurs at the edge of the fixtures, so it is considered that more force is required when opening the bag with fingers.

The Effects of Perforations

In addition to measuring the openability with notches, we also measured samples with perforations. The following are the measurement results.

_e-1024x391.jpg)

From the graph, you can see the fluctuations in force values due to the perforations. The force required to open the perforated bag is approximately one-ninth of the maximum force value needed compared to an unperforated bag.

We also noticed significant differences in the ripped surface after the test. Without perforations, the surface was slanted, and the film was twisted and stretched. In contrast, with perforations, the surface was straight and neat along the perforations.

Summary – Corporate Efforts to Improve Openability

As a result of measuring the openability of the heat seal bag, we confirmed the things below.

- With notches, the heat seal bag can be opened more easily with less effort.

- Perforations improve the openability and make it easier to open the heat seal bag straight.

Although the above results are limited to the samples we used, we hope you find them useful as a reference. For this test, we used visible and easily recognizable notches and perforations as samples. However, in actual film packaging, various techniques are implemented to improve openability, such as laser processing notch or perforations only in the surface layer film.

If you are interested in measuring how each ingenuity affects openability, please refer to the featured methods here.

Also, please check other related articles on Force Channel and measurement case videos in packing industry on IMADA’s website.