Q: Our measuring instrument is used every day for quality control checks. Do we need daily maintenance?

A: YES, basic operability checks and accuracy checks should be performed.

✓ Basic Operability checks:

Check whether the instrument works according to pre-defined operational requirements in safe and reliable functioning conditions, such as checking if the pushing buttons of the measuring instrument are smooth.

Check the appearance simultaneously; is any damage identified on the measuring shaft, dent on the outer shell, or unfamiliar responses in handling?

✓ Accuracy checks:

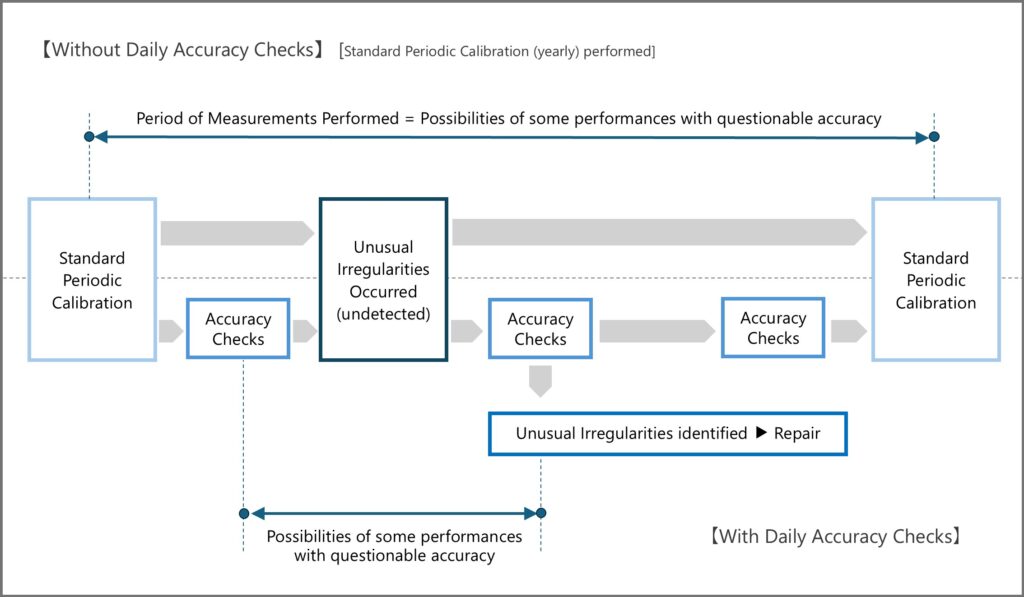

Regular calibration and adjustments are essential; however, daily in-house checks can help immediately detect unnatural issues.

In force measuring instruments, sudden changes in accuracy can occur due to overload etc. Overload could cause malfunction or severe damage to force gauges, but they can also affect accuracy only and making it incapable of performing accurate measurements.

Daily in-house accuracy checks (in-house calibration) and basic inspection help identify any unusual issues instantaneously and avoid leading to related severe problems in the future; early detection of unusual behavior of the measuring instrument in quality control plays an essential aspect in the management of the measuring instrument.

Other than accuracy, check the operability of functional buttons, the battery condition, and, most importantly, the measuring shaft status.

The measuring shaft must be firmly fitted and stable without distortion or damage. The force must be transmitted correctly to the sensor, and accurate measurements can be performed. Similarly, check any attachments and jigs applied. They should be free from any apparent scratches or damage that could cause significant issues with the measurement results.

IMADA offers dedicated kits for in-house daily accuracy checks and calibration services at the specialized calibration laboratory for IMADA measuring instruments and equipment. If unfamiliar responses are detected from your daily accuracy checks, please contact us for support and further assistance, accuracy adjustments, and repairs as required.

>> Click here for IMADA Products and Calibration Services