We recently visited one of the major packaging company in Poland, PACKPLUS.

PACKPLUS conducts quality control for their products such as product labels and packing items by friction testing, and compression and tensile testing.

With the help of Mr. Kristoff Trojanowicz, a Packaging Specialist from PACKPLUS, we would like to introduce some force measurements practiced in the quality control of the packaging industry.

PACKPLUS designs and manufactures packaging, labels, packaging materials, etc., for various beverage products, following customers’ needs and requirements.

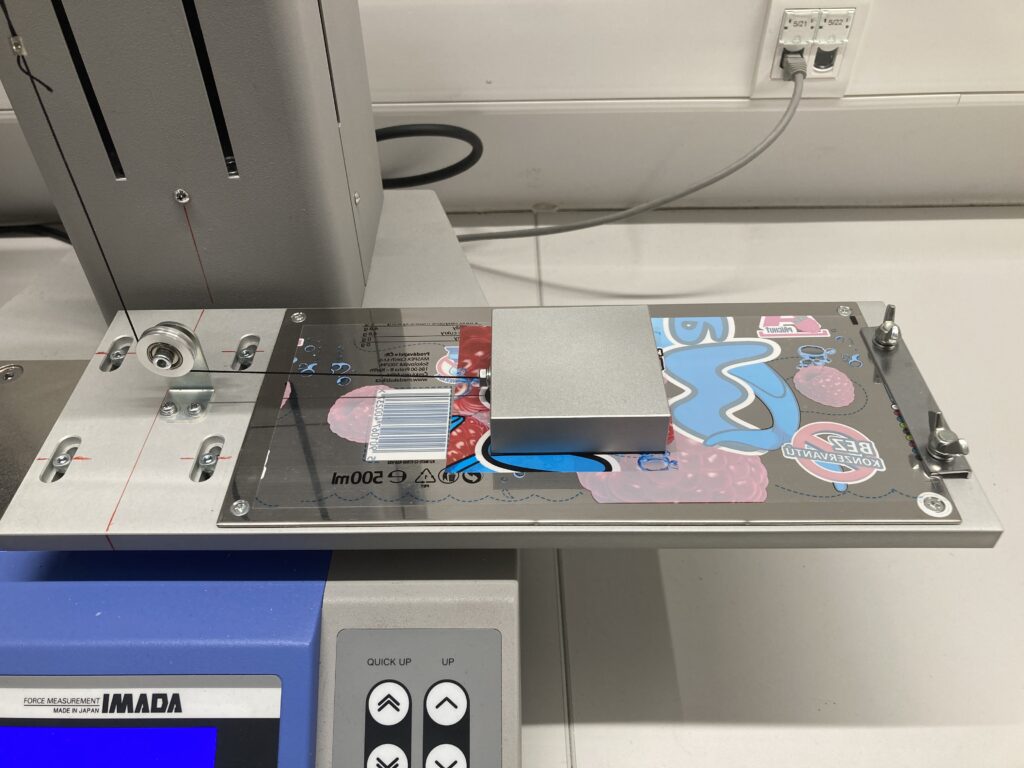

Among many manufactured beverage products, labels require quality control with force measurements. When the beverage products are produced in the production line, the labels needs to move smoothly enough to be attached onto the bottle. So coefficient of friction of the labels are supposed to be lower than the maximum values set by the standard.

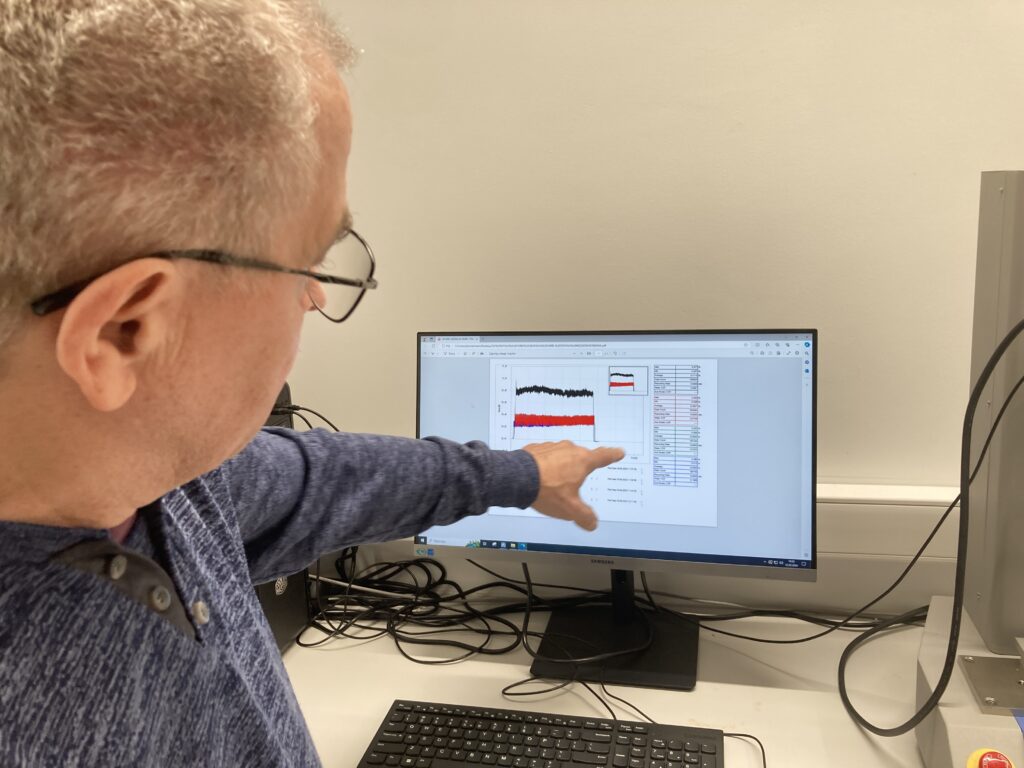

In the test, he confirms the coefficient of friction on the graph from the data acquired with the use of the motorized test stand pulling the weight at a constant speed.

The measurement results are overlaid on a standard evaluation graph (for basic comparisons) and reported to the customer.

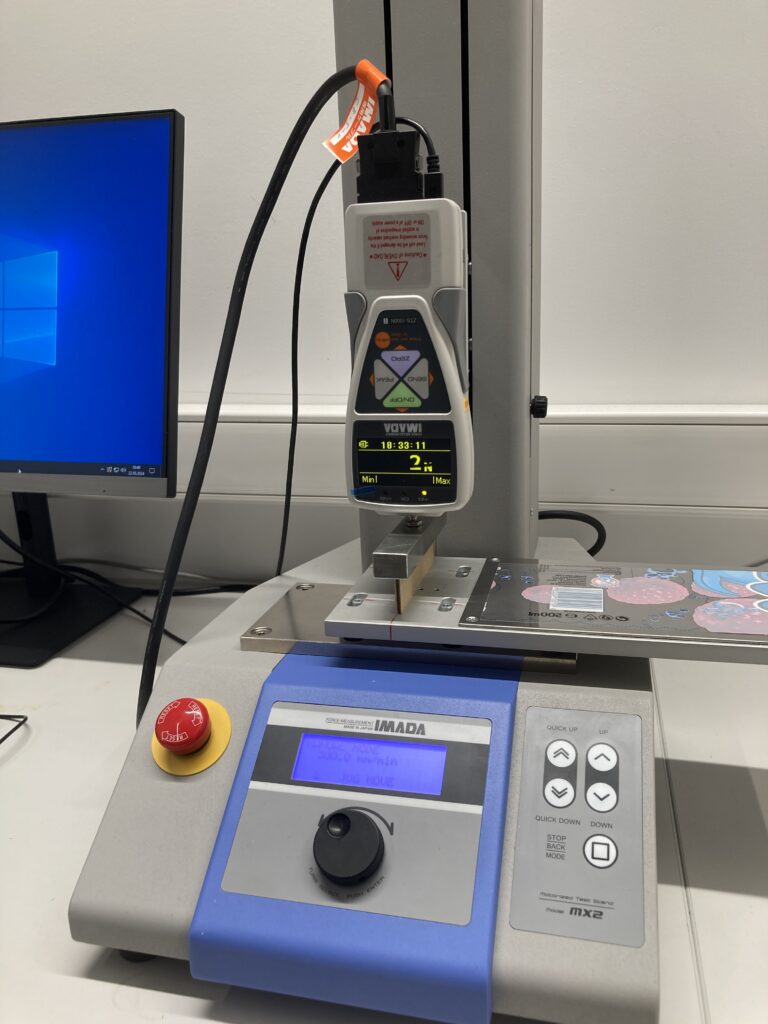

Other than the labels, additional compression test is applied to confirm the durability of the packaging materials for beverages.

The packaging material is cut to the compression jig size, placed in a holder to hold from both sides, and positioned directly under the force gauge.

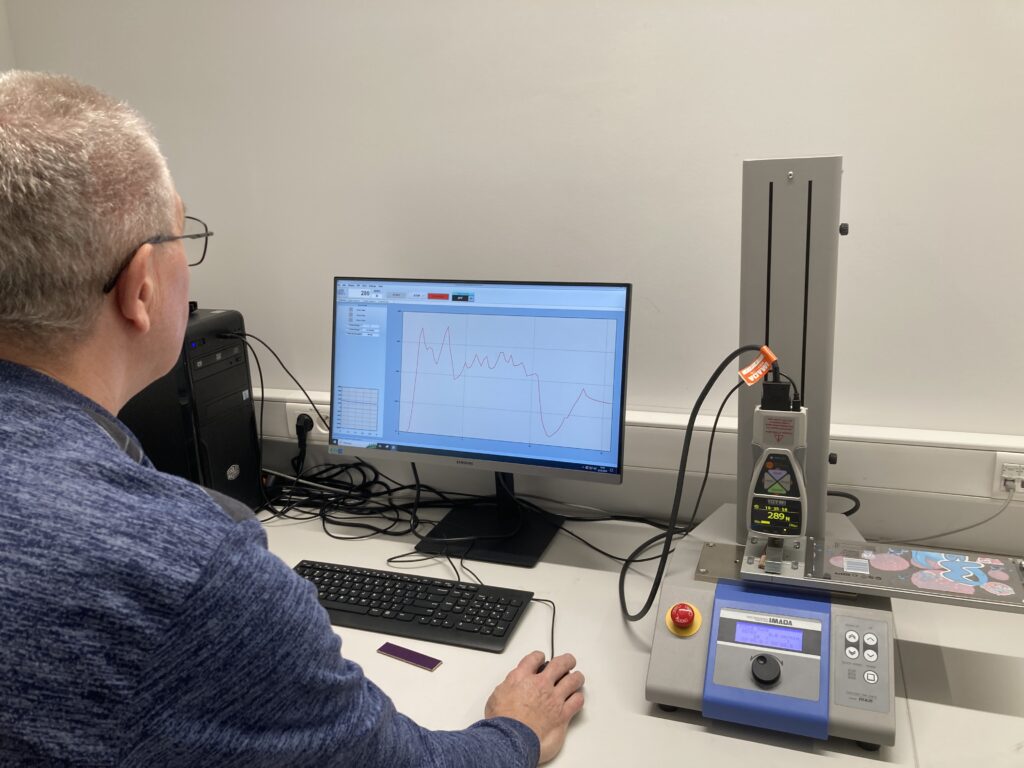

The material sample is then compressed with the same-size jig attached. We have noticed the stand and table have lines drawn on them to prevent the sample and jig from being off-center, indicating that they have been well used.

The force transition is recorded with the data graphing software in the compression test as well.

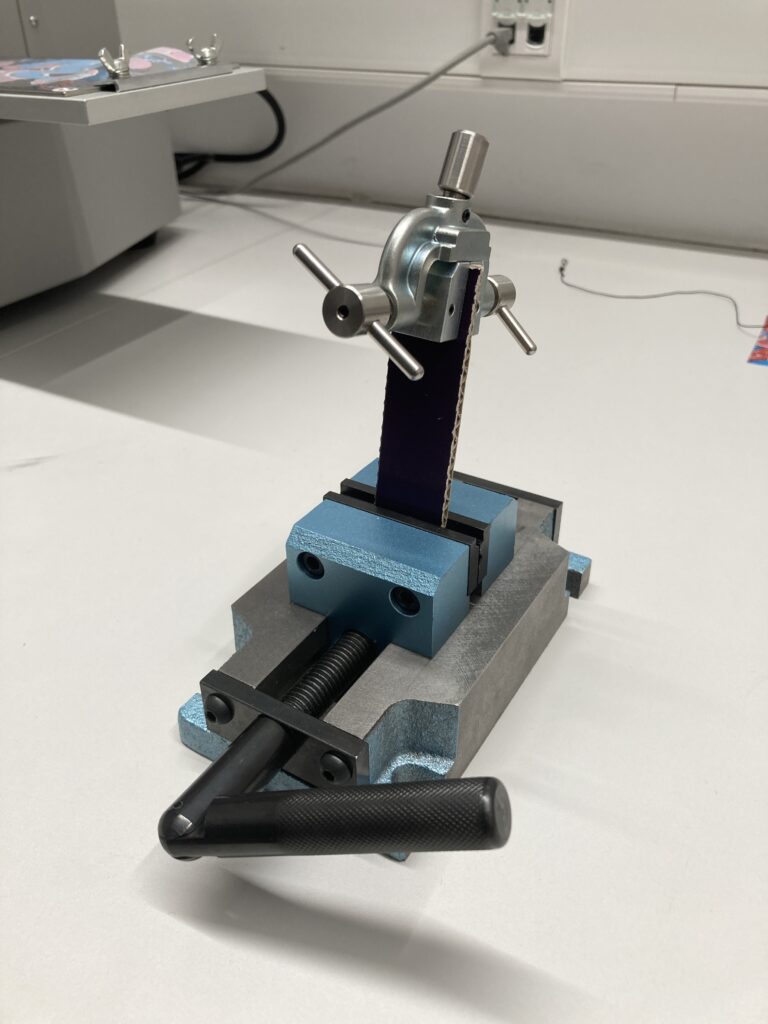

The tensile test is also conducted sometimes. The picture below shows how the sample is set with jigs.

In the packaging industry, force measurement is relatively common, and various material properties are being verified, mainly the durability of packaging materials that protect the contents, as in this case. Besides, quality improvements of packaging products are constantly being made using alternative materials that are lighter or more environmentally friendly. We will continue to focus on this industry as one where new force measurement solutions continue to be developed.