Film packaging is one of the most favored and convenient food packing materials, as seen in various snack bags and multiple pouches, such as potato chips. Film is also one of the standard materials for labels, and force measurement is one of the popular means used for quality control. This article introduces some examples of force measurements in the quality control of film packages and films.

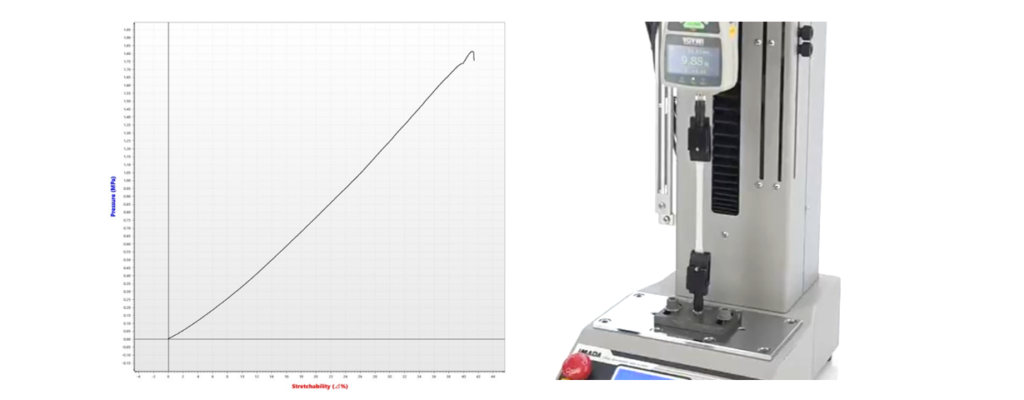

Tensile Strength Test and Stretchability Measurement

Tensile Strength Tests and Stretchability Measurements are some of the most well-known tests in film quality control and R&D. In a tensile strength test, a piece of film cut to a specific width is gripped with a specialized chuck jig and pulled vertically to measure strength at break*1. (One side of the sample is gripped with the specialized clamp installed to a measuring shaft of Force Gauge.) Stretchability Measurement is conducted as the tensile strength test to analyze the correlation between force value and stretchability.

Based on the chuck gripping distance at the start of the test, the film is checked for the amount stretched at a specific tensile force applied.

There is no definite answer to film strength or stretchability, and manufacturers individually conduct quality control schemes according to the standards determined by the required functions and purposes. For example, the retort pouch packaging films and the fresh food packages needing vacuum packaging should have different film properties.

In any case, to obtain accurate measurement results, the following are the key requirements:

- The equal sample width

- The equal sample gripped distance at the test start

- The constant test speed

For films with a high stretchability rate, which stretches and deforms to become thin, it is necessary to use a gripping jig, which increases the holding force automatically during the pulling motion.

*1 Depending on the standard, a dumbbell-shaped sample may be recommended.

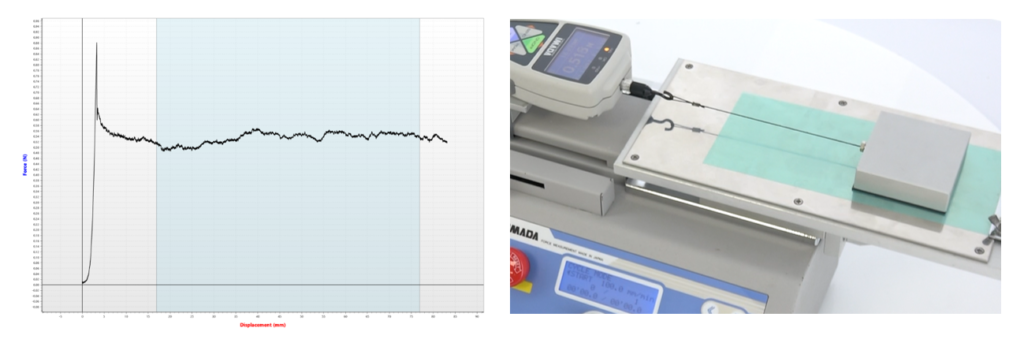

Friction Coefficient Measurement

The coefficient of friction is one of the essential film properties in the packaging manufacturing process.

>>What is the coefficient of friction?

For example, if the coefficient of friction for the film used for the packaging is exceptionally high or low, problems may be expected during film transportation (unstable conditions during the transportation could stretch or wrinkle the film, etc.) The unbalanced coefficient of friction for the quality requirement could affect work efficiency, requiring unnecessary time-consuming efforts leading to low performance.

To avoid problems as such, the coefficient of friction is measured and managed.

A standard test method is to fix a piece of film on the test stand table and slide the film fixed weight above to measure friction between the two sheets of film by measuring the friction force and coefficient of friction.

Theoretically, the coefficient of friction is not affected by the weight or size of the weight, but in actual cases, there are cases where it is affected. For example, JIS K7125 (1999) “Test method for the coefficient of friction of plastic films and sheets” specifies the weight and size of the weight, the test speed, etc., in detail.

Measure the Static Coefficient of Friction at the start of the movement and the average Kinetic Coefficient during the movement.

Heat Seal Strength Test

Heat sealing is a method for film packaging, which is inspected for its peel strength by force measurement. The fundamental test method is applied with a sample cut to a specific width. One end is gripped with a chuck jig attached to a force gauge shaft, the other is pulled to the opposite side, and the force value is measured when the heat seal peels off. (For more reproducible measurements, the use of a motorized measuring stand is recommended)

Since the measurement results vary depending on which part of the sealed section is cut for the measurement. Therefore, the average measurement results are taken from the multiple points for accurate evaluation. The heat seal peel strength test is also called the T Peel Test.

Ease of Opening Test

The need for easy-to-open packages varies for the elderly, children, or those with some physical difficulties, but also for convenience, evaluation of ease of opening is one of the challenges for many manufacturers. Examples of Ease of Opening Tests include Tear Strength Tests for Pouch Packages and Opening Tests for Cup Containers 45-degree Peel Test.

Tear Strength Test for Heat Sealed Pouch Packaging

The tear strength is directly linked to the ease of opening for the tear-to-open film packages, such as retort and stick-type pouches. The opening support V-notch dent is cut to ease the tearing process, making the tearing motion easier where required and with less effort, while the pouch maintains the shape and other functions unchanged.

Cup container opening, 45-degree Peel Test

The heat seal introduced earlier is also applied to seal the lid of the cup container, which is the peeling strength and ease of opening the cup container. The peel strength is measured by pulling the opening tab with a chuck jig attached to a force gauge and pulling it until it unseals to open.

The standards specify the requirements, and the seal is to be pulled from the top at the specified angle.

Summary

This article explicitly introduced quality control tests for films and film packages for food and beverage containers. In addition to the tests explained, various force measurement tests are performed on film packages. e.g., pressure tests and puncture tests (see related articles).

The Force Channel offers other interesting and useful articles. In addition, the IMADA product and service site is available for related case studies and other detailed information with more measurement examples and videos. Please use them for your quality control references.

>>Click for measurement example videos for food and beverage packages and containers.