The High Degree of Accuracy with the Reliable Performances

IMADA is a manufacturer of the Force-Gauges, pursuing research for Devices safe and long-lasting, durable with a high degree of accuracy and reliable performances with an extensive support system such as Repair and Maintenance Services and Long-term Support Services for the discontinued models.

Calibration is the essential service in handling the measuring instruments and focusing on improving our Management System.

Introduction to IMADA’s Calibration System and Services:

- Purpose of Calibration

- Methods of Calibration

- For Progressive Calibration Services

- Initiatives as an ISO/IEC17025:2017 Accredited Laboratory

Purpose of Calibration

The measurement capability and the accuracy of the Measuring Instruments protected with regular

Calibration for the capability maintenance under the established management system. The deterioration of measuring instruments results from the wear and tear, the frequency of use, damage, and those stored unused for a certain period. The Quality Management System ISO9001 issued by the International Organization for Standardization (ISO) clarifies the measurements necessary to maintain quality and requires appropriate management, including Calibration of the measuring instrument. IMADA defines Calibration is the essential service to demonstrate high-quality Measuring Instruments.

Calibration Method

The Calibration, in the **Japanese Industrial Standards (JIS), defined under the Glossary of Terms Used in Measurement JIS Z 8103:2019:

Step 1: Under specified conditions, the relationship established with Uncertainty between the Value of quantity with Uncertainty provided by a Measurement Standard and the corresponding indicated Value.

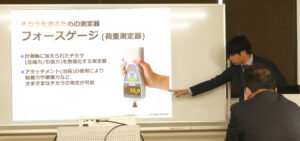

Step 2: The operation from the information establishes a relationship to obtain the Measurement Results from an indicated Value. Calibration is the process of checking the difference between the Value indicated by a Measuring Instrument and the Value indicated by a Standard. In the Force-Gauge Calibration, the Force applied with a Weight or a Load-Cell, the Working Standard, checks the difference between the Displayed Value and the Working Standard. The Working Standard used here is Calibrated by the highly accurate Secondary Standard, controlled by the unbroken chain of comparisons up to the National Metrological Standards. In this way, IMADA can provide the traceable standards associated with National Metrological Standards to deliver reliable Force-Gauge Calibration results.

**JIS: Japanese Industrial Standards specifies the Standards for Industrial activities in Japan.

The standardization process coordinated by the Japanese Industrial Standards Committee(JISC), under the Ministry of Economy, Trade, and Industry(METI), for deliberating on industrial standards, searchable database available (in Japanese only). JISC also responsible for Japan’s growing contribution, setting International Standards through work with the International Organization for Standardization(ISO) and the International Electrotechnical Commission(IEC). *Details provided upon request.

For progressive Calibration System and Services

IMADA is committed to providing a progressive Calibration System and Services. The Calibration level controlled with, maintaining, and improving the Environment, Technicians, Equipment, including Measuring Instruments and operating the Calibration Laboratory. The temperature and humidity that affect Calibration kept within a specific range, the facility organized with less prone to external factors such as vibrations and minimize their effects through daily monitoring. Only the certified personnel to perform Calibration operations, and Force changes regularly monitored through work comparisons. The Calibration Standard: the weights and the Lord-cells with the periodic check systems from multiple angles coordinated, enabling the early detection of abnormalities. To support customer convenience, for minimizing the downtime, the system organized enables to complete and provide reliable Manufacturer Calibration Service within seven days as a standard.

Initiatives as an ISO/IEC17025:2017 Accredited Laboratory

ISO/IEC 17025:2017, the International Standard assigns the criteria for accreditation Calibration Laboratories with a Management System and technical competence (such as facility, equipment, techniques) enable them to submit Data worthy of international trust. PJLA: The Accreditation body exchanged Mutual Recognition Agreements (MRA) with APAC (Asia-Pacific Accreditation Cooperation), ILAC (International Laboratory Accreditation Cooperation) the member of NACLA (National Accreditation Cooperation for Laboratories). The ISO/IEC 17025 Certificate issued by IMADA Calibration Laboratory accredited by PJLA valid in the Signatory Countries. In ISO/IEC 17025 CALIBRATION, the Calibration procedures precisely regulated than standard manufacturer Calibration. As an output, a Calibration certificate with the PJLA and ILAC MRA Symbols issued. These symbols certify that the Calibration performed by a Calibration Laboratory with high technical competence and technical competence with international recognition. IMADA is an accredited ISO / IEC 17025: 2017 Calibration Organization engaged in the Calibration Service for Force-Gauges. The organized Management System based on ISO / IEC 17025: 2017 reduces the uncertainty of Calibration operations and provides highly Secure and Reliable Services.