We, IMADA, aim to create an organization where each employee contributes to the society through his/her work and can nurture satisfaction for the career. As IMADA’s participation in the SDGs promotion partner program of the local municipality shows, we take various initiatives for SDGs. Here, those initiatives related to our factory are spotlighted.

For Goal 8: Decent Work and Economic Growth

We believe that a company should provide the circumstance where everyone can be highly motivated and perform at their full potential. Our factory is designed to create such circumstances by following ideas.

Center-located office

Though it may be more common to locate the office area at the corner in factories in Japan, our factory places the office at the center of the entire area.

This is because we want to encourage communication between employees so that they can establish more rapport with each other, leading to better working performances and the vigorous working environment.

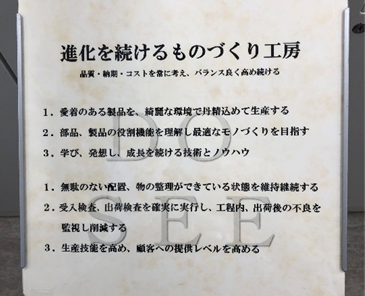

-Continuously evolving atelier

This is the fundamental concept of our factory. We consider our employees at the factory as artisans, which means they always pursue Kaizen for more elaborate outputs. To support their skill improvement, we provide workshops about manufacturing techniques and also encourage individual studies related with production.

For Goal 12: Responsible Production and Consumption

The idea of this goal requires a manufacturer to reduce waste as much as possible and to avoid overproduction to protect natural resources. Our contribution to this goal is to prolong the lifespan of our products resulting in less frequent product purchase and decreasing the consumption of product materials and wastes. We realized this longer product lifespan by enhancing the product durability and improving our repair and maintenance service.

-Enhancing the product durability

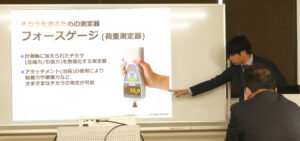

Our products are made with a meticulous mechanism to increase durability.

For example, our Force Gauge alarm function protects the device from overload damage, and the chuck jig Grip is heat-treated with special steel to enhance wear resistance. Aluminum is used for the outer covers of the force gauges and the torque gauges.

-Repair and maintenance service

We offer after-care services for the products to take care of repairs and maintenance services, including some very old models as well.

The Calibration facility is also available, and regular yearly maintenance is highly recommended for accurate measurement and longer lifespan of the devices.

As a part of the global community, we continue to act for SDGs. As a Manufacturer, both Goal 8 and 12 are especially important to us.

We continue to aim for higher goals for a better environment and a better future.