To perform peel tests more effectively, there are several key points to consider. While there is a standard “JIS Z 0237 (2022)”, by Japanese Industrial Standards Committee, which specifies the peel test method for adhesive tapes and sheets, it can serve as a valuable reference when not conducting measurements based on the standard, and even when testing samples other than tapes or sheets. Therefore, we would like to provide some insights on how to conduct peel tests more effectively by following JIS Z 0237 (2022) and considering various aspects.

There are five points to consider:

- Maintain a constant test speed

- Peel off straight

- Pay attention to temperature and humidity

- Proper adhering surface preparation

- Adhere the testing specimen evenly and straight

Points 1-3 are common to all peel tests, and points 4 and 5 are essential, especially for the pressure-sensitive adhesive tapes. Let us look at the details individually.

The texts in Blue are the quotes from the JIS Z 0237 (2022) “Testing methods of pressure-sensitive adhesive tapes and sheets”, and the bullet numbers of the quoted source(courtesy translation only).

And, the texts in Black and Red are based on the perspectives, opinions and explanations of IMADA Co., Ltd.

Maintain a constant test speed

In a peel test, it is essential to keep the peeling speed constant to determine the average force required to peel the specimen. Any variation in the peeling rate will affect the average value. Thus, it is highly recommended to use motorized test equipment to peel the test specimen since manually peeling methods is challenging to maintain a constant peeling speed. JIS Z 0237(2022) defines the test speed as follows:

“5.0 mm/s ±0.2 mm/s” (10.4 Determination of peeling adhesive strength)

“Ignore the first 25 mm long measurements from the start of the testing. Then, average the adhesive strength measurements of 50 mm lengths pulled from the test specimen, and use it as a value for the peeling adhesive force. “(10.4 Determination of peeling adhesive force)

Even if not adhering to the standard, when testing specimens such as adhesive tapes or sheets, it is advisable to peel at a speed of 5.0 mm/s ± 0.2 mm/s (approximately 300 mm/min). Furthermore, it is recommended to disregard the initial 2.5 cm of peeling and focus on the subsequent measurement values. This approach ensures accurate results. Whatever the test specimens are, constant test speed is always essential.

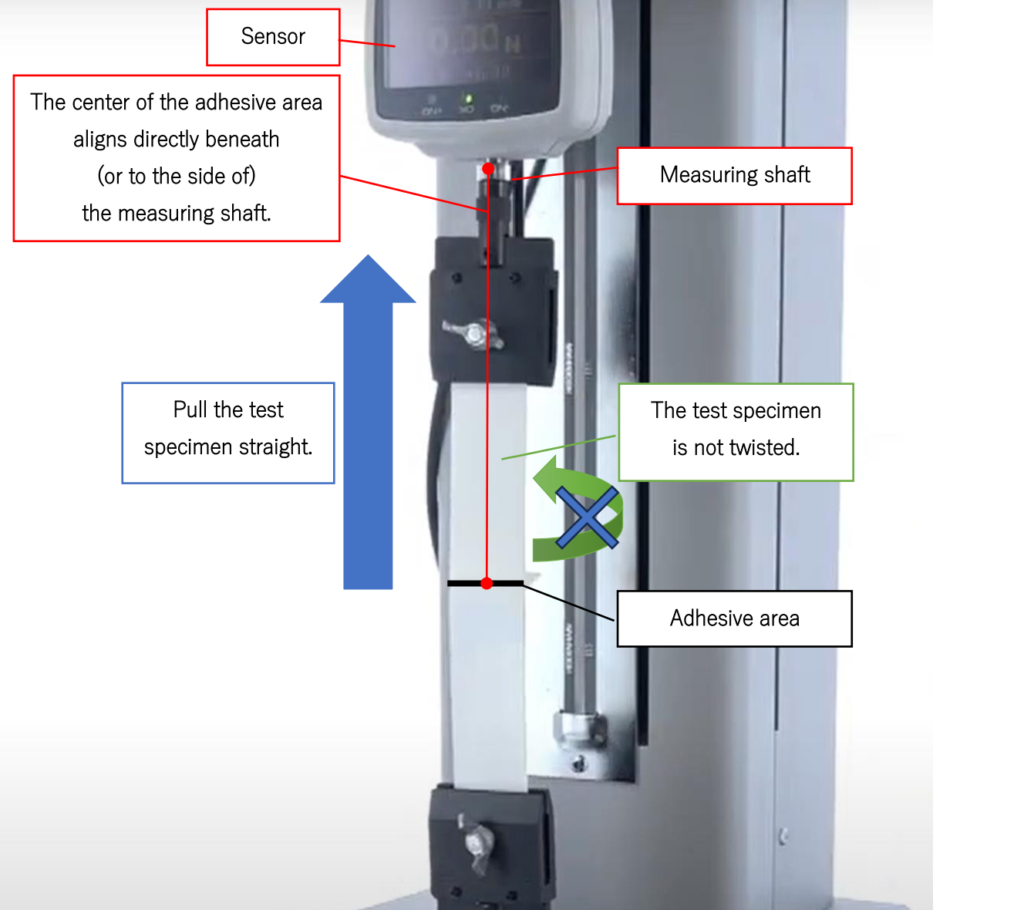

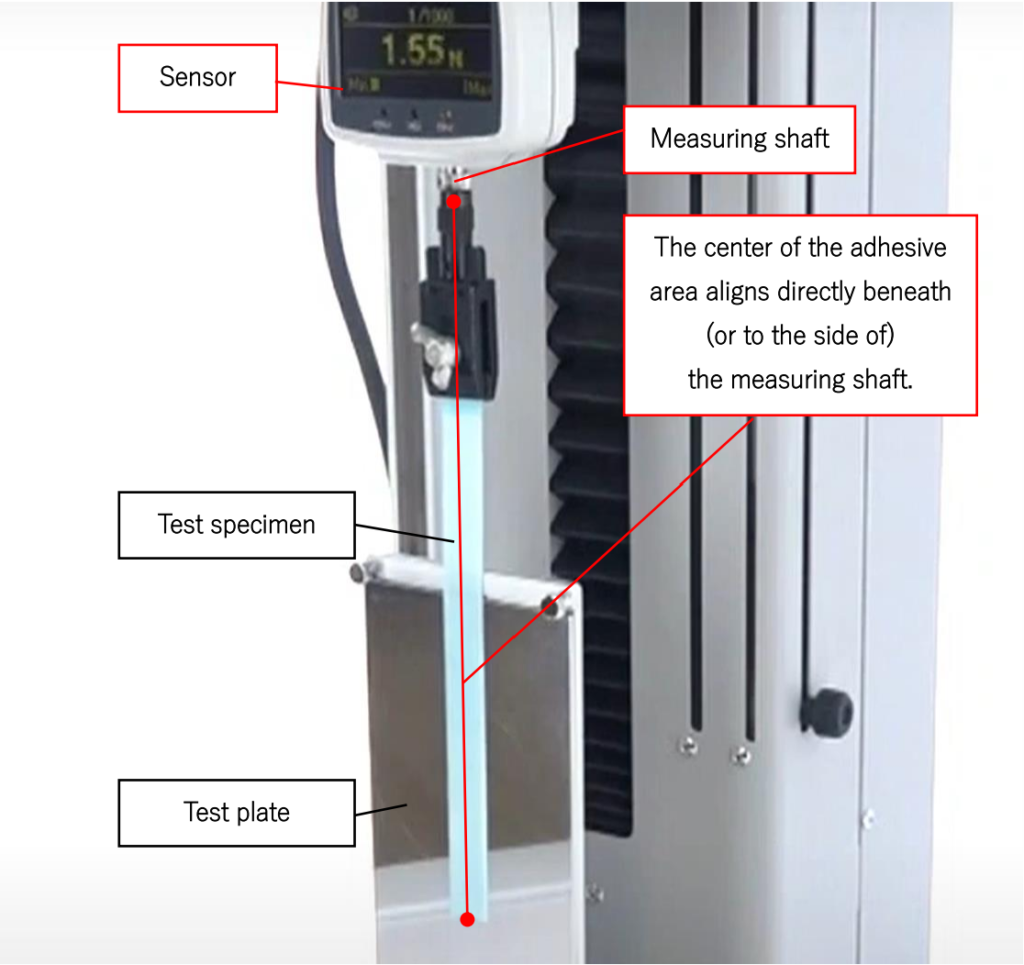

Peel off straight

In peel testing, there is always a process of pulling to initiate peeling (attempting to peel), and it is essential to pull off straight while maintaining an arbitrary angle. If the test specimen is twisted or pulled at an uneven angle, the peeling force would not be transmitted to the sensor well, leading to inaccurate test results.

Pay attention to temperature and humidity

Adhesion is significantly influenced by temperature and humidity. So, in JIS Z 0237(2022), ambient temperature and humidity are defined as follows:

“In the absence of specific instructions, testing is conducted under standard conditions (Temperature 23 ℃ ±1 ℃, Humidity (50 ±5) %)” (10.3 Test method, 10.3.1 General)

It is ideal to conduct tests in an environment where temperature and humidity can be maintained at a constant level, although it may not always be as described above. (Of course, if you need to make measurements that comply with the JIS standard, you must adhere to the above numbers.)

Points 4 and 5 from the following are for especially when testing pressure sensitive adhesive tapes.

Proper adhering surface preparation

When performing a peel test of adhesive tape, the test specimen must be appropriately adhered to a test plate. If there are issues with the surface of the test plate where the test specimen is adhered, you cannot obtain accurate test results. In other words, it’s important to adhere the test specimen in the best adhesive condition.

See what the specifications in the JIS Z 0237(2022) are:

“The adhesive surface of the test plate must be free from dust or foreign particles, and it should not be touched by bare hands or come into contact with any other contaminants.”(Section 10.1 Test specimen)

a) The cleaning solvent for the test plate can be selected from one or more of the following: diacetone alcohol (4-hydroxy-4-methyl-2-pentanone), methanol, methyl ethyl ketone, acetone, and n-heptane. The solvent must be equal to or higher than reagent grade or residue-free industrial chemicals. (Section 10.2.2 Test plate a).

b) Soaking a selected solvent from a) into a cloth or similar material, wiping the surface of the test plate. After it has dried, further wipe it thoroughly with a new cloth or similar material. This cleaning with the solvent is repeated three or more times until it is visually determined to be clean (Section 10.2.2 Test plate c)

The best condition for the test plate’s surface satisfies requirements A to D as follows. When there is no need to comply with the JIS standard, cleaning the surface as described below is sufficient.

A. No moisture ← Wipe using a dry cloth.

B. No oil content ←Wipe with a cloth soaked in alcohol, etc.

C. No dust or other debris ←Sweep by a brush or dry cloth.

D. No scratches ←If there are apparent scratches, it is recommended to replace it to new one.

*Cloth, such as surgical gauze or non-linting cotton, is recommended to avoid generating debris and damaging the surface.

The main idea is to avoid touching the surface and keep it in a clean condition without any scratches or dirt.

So, what material is recommended for the test specimen mounting plate?

JIS Z0237(2022) specifies that plates with the following specifications is used:

“The test plate is a SUS304 steel plate specified in JIS G 4305 with a surface finish of BA (bright heat treatment after cold rolling), and the surface roughness was Ra: 15 nm to 75nm, specified in JIS B 0601.”(10.2.2 Test plate)

The roughness is specified for the measurement per the JIS standard, and a stainless-steel plate with a mirror-like luster surface is required to meet the condition. However, using a shiny stainless-steel plate without dirt or scratches is usually sufficient.

Adhere the testing specimen evenly and straight

The purpose of cleaning the test plate’s surface is to ensure consistent adhesion of the test specimen, thereby preventing potential detachment-prone areas resulting from contamination or other factors.

JIS Z0237(2022) states:

“The Test result is invalid with identification of air bubble(s) “(10.3.2 Test procedure)

This highlights the importance of uniformly and consistently applying the test specimen with a consistent strength in peel testing. This is why JIS standards specify the use of pressure rollers like the one mentioned below.

Even if complying with the Standards is not required, it is recommended to use a rubber roller such as the one above to apply adherence pressure to the test specimen for consistency. It would also help avoid operator’s body heat transmissions.

Incidentally, when using such a roller, the aim is to apply pressure evenly by the weight of the roller alone, so you should press the test specimen using the roller without exerting additional force from above. The video from the link below shows how the tape is applied using the roller.

It is also essential to adhere straight. In point 2, we emphasized the importance of peeling straight, but if the tape is not applied straight from the beginning, it will be challenging to peel it off straight. Whether applying or peeling, always strive for a “straight” application.

JIS Z 0237 (2022) also specifies the following:

“The test specimen should be tested within one minute after roller pressure application.” (10.3.2 Test procedure)

Even if you are not conducting measurements in compliance with the standard, it’s a good practice to limit the time between pressure application and starting the test to ensure consistency.

Lastly

We, IMADA, are the manufacturer of measuring instruments with peel testers. As a peel tester manufacturer, we have introduced an example of performing a practical peel test.

Please visit our website below for more details about peel testers.

“>180-degree peel tester & how to perform measurement complying with corresponding part of JIS Z0237(2022) or ISO 29862(2018) >

“>90-degree peel tester >

“>Peel testing examples(video) >

Source: JIS Z 0237(2022) “10 Adhesion” of “Testing methods of pressure-sensitive adhesive tapes and sheets”