Q: I am considering bonding metal parts together using adhesive and would like to conduct adhesive strength tests. In the previous article, the lap shear test was introduced, but could you also tell me about tensile tests?

A: Tensile Test is a test method that applies a tensile force perpendicular to the adhesive surface to measure the breaking strength (the force value at the time of breakage). It is often used to test the strength of adhesives for adherends that are difficult to deform, such as metals and hard plastics. The choice between a tensile test or a lap shear test should be made based on the type of load that will be applied to the adhesive surface during actual use (one option is to perform both tests). It should be noted that there is not necessarily a correlation between the results of a tensile test and a lap shear test.

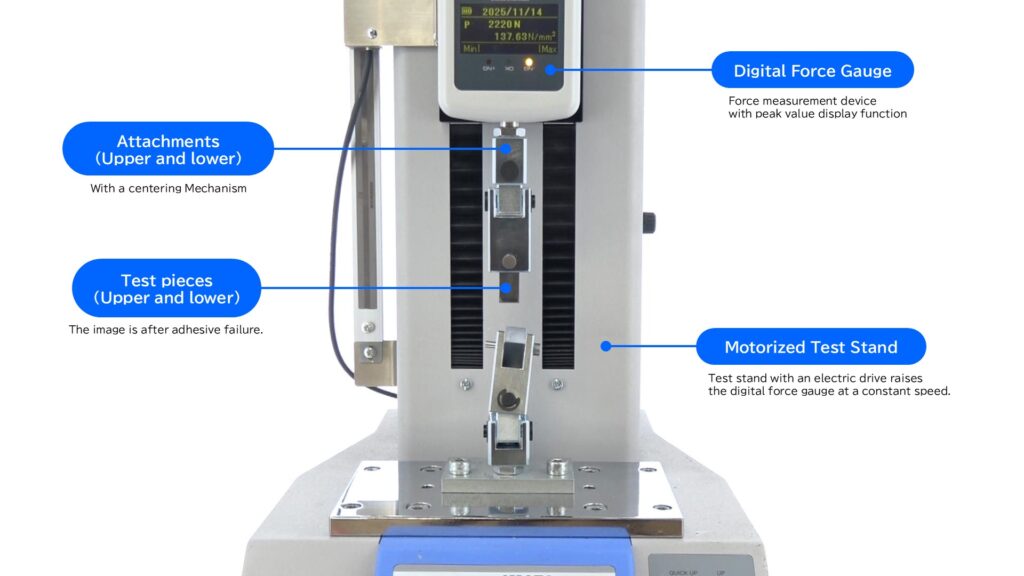

In adhesive strength tests, the force values to be measured often exceed 500N. For this reason, testing equipment with an electric drive (force gauge + motorized test stand, etc.) is often used. For force gauges, it is recommended to use a digital force gauge with excellent sampling speed in order to accurately measure breaking strength. In addition, the test jig must have a mechanism that applies a tensile force perpendicular to the adhesive surface. The test procedure is quite simple and is as follows:

| [Step 1] Adhere the test pieces together (be careful not to misalign or tilt the test pieces) | [Step 2] After the adhesive hardens, attach the test piece to the jig | [Step 3] Pull the test piece up and down and measure the force at break* |

|---|---|---|

|  |  |

*Force at break = maximum force value in the test.

When conducting the test, the most important thing is to apply a tensile force perpendicular to the adhesive surface. If a tensile force is applied at an angle to the adhesive surface, not only will the adhesive strength not be measured accurately, but it may also cause damage to the measuring instrument. For this reason, it is necessary to use a jig with an automatic positioning mechanism (for example, a centering mechanism) for the test.

Additionally, the test speed has a significant impact on the test results. The faster the test speed, the greater the force value at break, so it is important to standardize the test conditions when comparing samples. For example, JIS K 6849 (1994) “Testing methods for tensile strength of adhesive bonds” specifies that the test speed should be adjusted to a load rate of 3.92kN per minute or less, or the crosshead movement speed should be 50 mm per minute or less.

Test results are recorded as maximum force values (units: N, etc.) or maximum force values per unit area (units: N/mm2, etc.). For example, the maximum force value per unit area (N/mm2) can be calculated by dividingthe maximum force value (N) by the adhesive area (mm2). Calculating the maximum force value per unit area allows you to know the characteristics of the adhesive, which is useful for calculating adhesive strength during actual use and comparing test results with different sample sizes.

JIS K 6849 (1994) specifies that the maximum force value per unit area (N/mm²) should be calculated. Furthermore, it specifies that the test should be performed at least five times under identical conditions, and the average value of all measured values should be calculated.

This concludes our introduction to the tensile test, a method for evaluating the adhesive strength of adhesives. Although not mentioned in the main text, the adhesive strength of an adhesive is affected by its compatibility with the adherend. For this reason, when conducting adhesive selection tests, we recommend creating test specimens using the material of the actual parts. Additionally, while there are no absolute rules regarding the size and shape of test specimens, JIS K 6849 (1994) does include information regarding test specimens. Referring to the standard may be an option.

Force Channel provides a variety of information related to force measurement, including introductions to measurement examples. Also, IMADA’s product service site publishes various force measurement case study videos. For the “tensile test of adhesives” introduced this time, videos and test equipment configurations are also available from the link below. Why not take this opportunity to check it out?

>>Click here for Test Units of Tensile Adhesion Test of Adhesives