In the 1st and 2nd articles on the Compression Testing series, we focused on confirming strength with some examples. This 3rd article from the series focuses on examples of Compression Testing based on usability: – Tactile Sense Evaluation, Operability, and Functionality.

Operability Evaluation

In consumer products, there may be issues and dissatisfaction with operability that may lead to concerns. For example, using a stiff keyboard causes finger fatigue, potentially leading to tenosynovitis. Car brakes may require hard pressing to react or may respond too promptly to extremely light pressing, which could lead to serious accidents.

What the manufacturer considers suitable may not align with individual tactile senses. Moreover, the operability of the same product should not vary. Most importantly, the manufacturer should provide products with suitable usability of the same standard to ensure customer satisfaction.

In some cases, operability is judged solely based on the personal senses of the manufacturer’s inspector. However, it is often possible to quantify the forces required to operate a product through compression testing and in such cases, measuring values can set numerical standards to guarantee the product quality including operability.

The following case study is an “Operability Evaluation with Compression Testing.” Additionally, please visit IMADA’s website for reference videos of compression testing, available at the link below.

>>Compression test example video

Operability Evaluation Case Studies

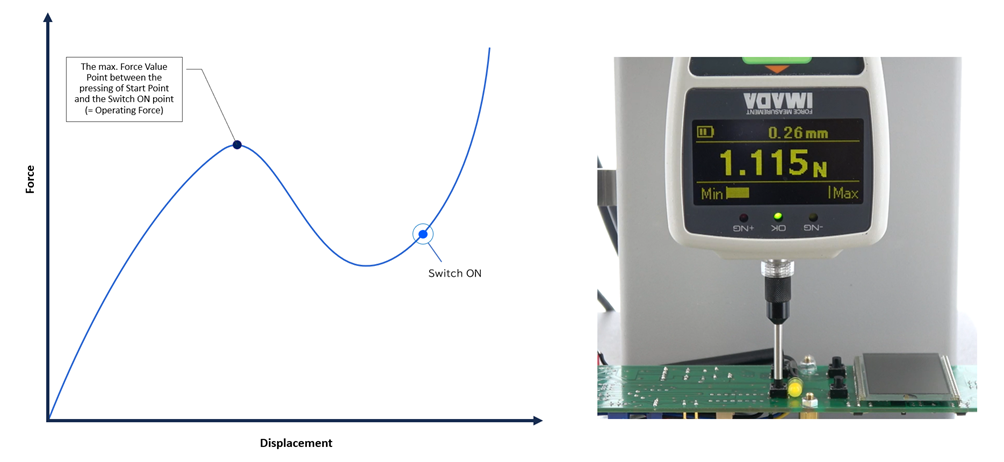

Operating Force Measurement: Push Button Switches

Push-button switches are used in a wide range of products, including mechanical keyboards, ignition switches, and equipment operation system panels. In many push-button switches, the resistance to being pressed goes up and down physically before the Switch is activated (see the graph below), but in any case, the maximum force value to turn switch on (= operating force) is a very important factor in evaluating operability.

The up-and-down movement of the force value before the switch is actuated creates a clicking sensation and the ability to recognize the actuation of the switch intuitively.

The Operating Force is measured by pressing the button using a Force Gauge. The ON / OFF state of the switch must be checked separately, but depending on the measuring instrument, the Switch-ON timing can be displayed on a graph. Note that if measuring the maximum force value only without a graph, ensure the operating force measurement is conducted correctly, meaning the pressing force will not exceed the operating force if a push-button switch is continuously pressed down even after it bottoms out.

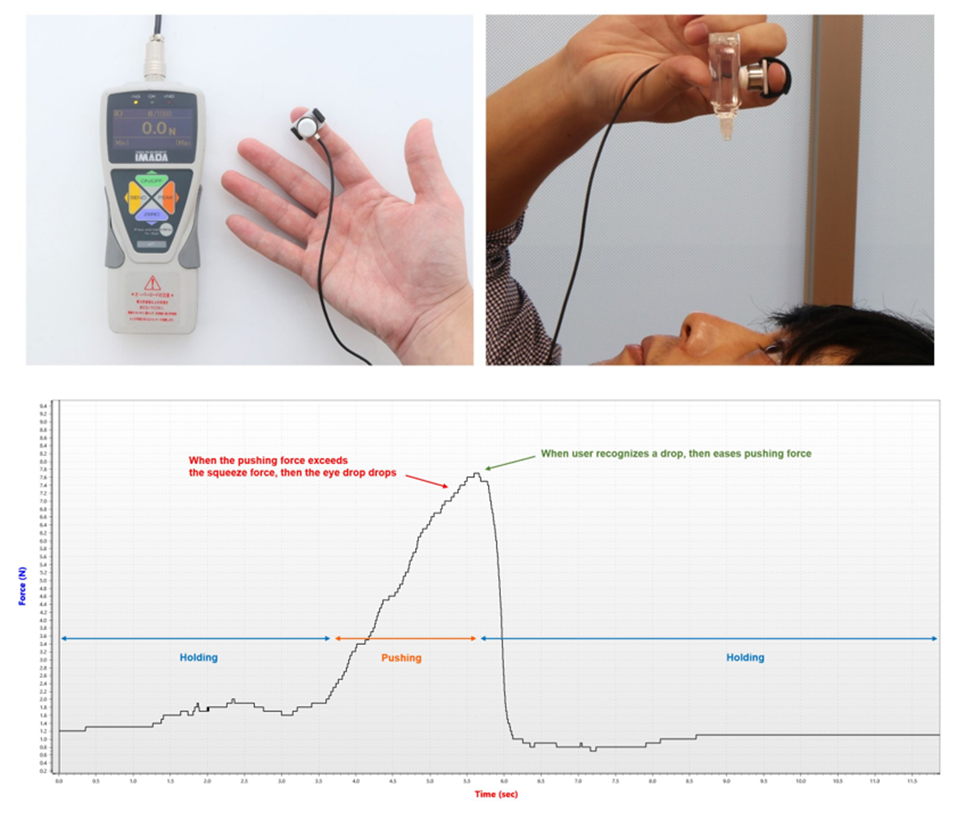

Squeeze Force Measurement of the Eye Drop Dispenser Bottle (Ophthalmic Squeeze Dispenser)

A compression test can quantify the squeeze force required to drop an eye drop from an Eye Drop Dispenser Bottle. The amount of squeeze force is an essential factor directly affecting the ease of use. The eye drops should be easy to apply with the appropriate squeezing force to allow a drop; if the squeeze force is too large or too small, it would be challenging to proceed with a simple process.

Squeeze forceis measured with a force gauge; the bottle is pressed from eye drop to drop, and the amount of squeezing force applied with the finger directly affects the ease of use.Although it is difficult to accurately determine the force value at the time of the drop dispensing, it is possible to determine the squeezing force approximately.

A force sensor (load cell) is fitted to the fingertip to measure the squeezing force.

Quantification of Texture and Tactile Characteristics

In the earlier text, we introduced how compression testing can be used for operability evaluation. This article further explores the essential role of Compression Testing in quantifying texture, including tactile characteristics. Similar to operability, the compression test evaluation alone cannot comprehensively analyze textures / tactile characteristics; therefore, separate assessments of the individual component elements are required to quantify textures.

For example, the texture of food can be classified into individual components, such as chewiness, mouthfeel, and smoothness. Among these elements, food hardness significantly impacts overall textures. Compression Testing is highly effective for evaluating and quantifying food texture from a physical perspective.

Additionally, various fields have previously studied the elements that constitute texture. The push button switch mentioned earlier serves as an example. Different research institutes have introduced research studies with specific standards for reference.

Quantification of Texture Examples

Measuring the Hand Feel (tactile characteristics) of the Push Button Switch

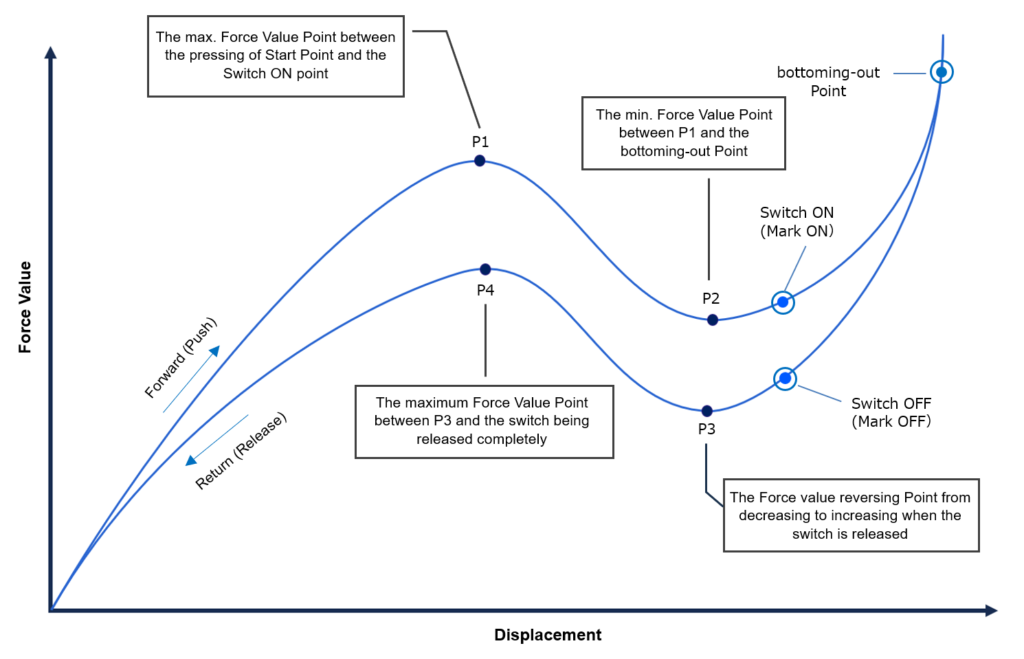

The Push Button Switch was introduced as an example in operability testing *1, where research has been conducted on the tactile characteristics feedback of the switch. The international standard ASTM F2592-16 (abolished in 2016) outlines several parameters determining the switch feeling when pressed.

The measurement method is not significantly different from the operating force measurement. However, in the push feel measurement, the maximum force value is obtained during the finger-pressing process, and the force transition is recorded until the finger is released. This data is then converted into a specific parameter for evaluation. Measuring both the force value and the amount of pressure applied simultaneously is standard practice.

● Parameter Examples for Switch Feel Evaluation

| Operating Force | Push-in force required to activate the switch (Force value at P1) ● The switch operation becomes heavier as the operating force is more significant. ● The smaller the operating force is, the lighter the switch feeling is. |

| Click Rate | The numerical index of the switch push-in feeling. Force values P1 and P2 ratio: {(P1 Force value – P2 Force value) / P1 Force value} x 100(%) ➡ The clicking sensation tends to decrease with the click-through rate. |

| Stroke | The pressing distance of how far to be pressed to turn ON and how far to be pressed to reach each point (P1, P2, etc.) ➡ Feelings such as smoothness and sharpness are influenced. |

| Releasing Force | The force value of the switch to return after being released. (force value at P3) ➡ The greater the releasing force, the stronger the pushback force upon release. |

*1 The switches applicable are limited to push-button switches with a temporary resistance drop after a rise in resistance can be measured (switches include tactile and membrane switches with a clicking sensation).

Summary

In this article, we have introduced the quantification of operability and tactile characteristics feedback in Compression Tests; these can be applied in various contexts by deconstructing problems into their component elements, including assessments of switch actuation. Moreover, the applications mentioned, such as Compression Tests, are critical in evaluating safety and protective performance. Please explore a range of measurement examples with demonstration videos available on the IMADA website.