When conducting Friction Tests and Friction Coefficient Measurements, it is essential to note several cautionary points for adequate measurement precision and reproducibility*1. We are introducing 5 valid key points and tips helpful for all friction tests in force measurements, including essential topics such as Test Speed Uniformity, etc.

[5 Practical Key Points to Improve Reproducibility in Friction Tests]

- Achieve Uniform Test Speed

- Cautionary Action to Vibration

- Weight Pulled Horizontally at Straight Angle

- Correct Sample Orientation Placement

- Cautionary Attention to Surface Condition: Differences and Changes

*1 Force Measurement Reproducibility refers to the degree of agreement in measurement values with repeated measurement of a single sample type of the same condition. For measured value assessments, high reproducibility is essential for reliability.

This article is focused on the reproducibility of friction testing by surface-to-surface contact with sheet form samples such as paper, film, etc. Please refer to the previous article Introduction to Friction Testing (1) Surface-to-Surface Contact Friction Testing'” at the link below for Key measurement details.

Achieve Uniform Test Speed

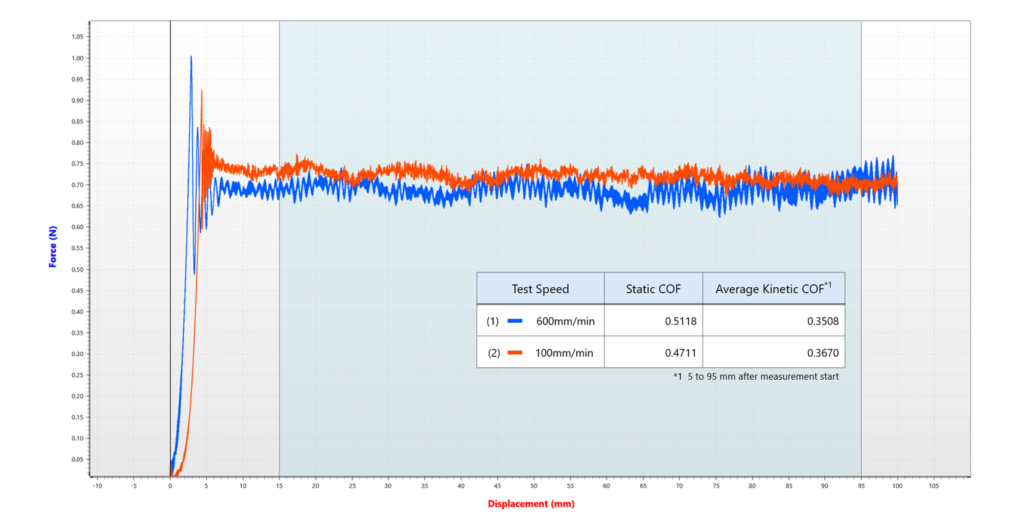

All Force Measurements, not limited to friction tests, are essential to achieving high reproducibility with test speed uniformity. The graph below is an example of force-displacement overlapping the measurement results: (1) at a test speed of 600 mm/min and (2) at a test speed of 100 mm/min, and the apparent difference, especially with the static friction coefficient.

In theory, friction force can be calculated from the surface characteristics (friction coefficient) of the object and normal force, and realistically, it is known that the test speed and contact area have a significant impact on the measurement results. Achieving steady uniformity in friction testing is essential, and every operating condition of the measurement conducted for a particular evaluation must always be precisely the same for accurate measurement evaluations.

There is no absolute rule for the test speed, but one option is to refer to the test speed specified in the standards, such as “ISO 8295 (1995) 100±10mm/min” and “JIS P8147 (2010) 10.0±0.2mm/min”. The Motorized Test Stands and specialized Friction Testers enable steady speed control and are highly recommended for your references.

Cautionary Action to Vibration

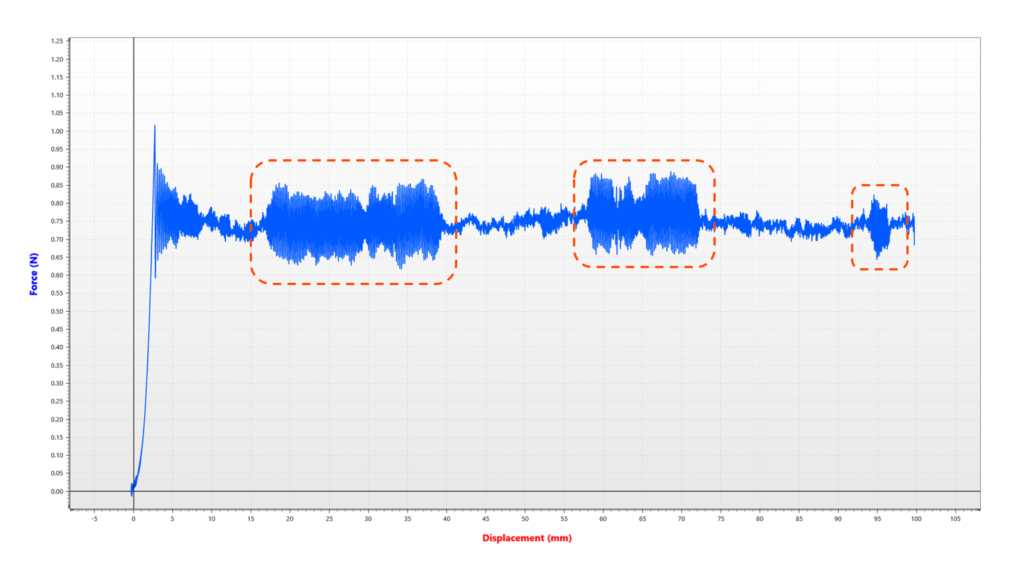

For friction tests such as papers and films, the weight used is usually less than 1000g, so the friction force is small, which means it is easily affected by the vibration during the measuring process. For example, in the friction test of plastic films specified in ISO 8295 (1995), the maximum measured value is often below 1 N.

The graph below shows the effect of the vibration intentionally applied to the tester during the measurement. The more significant force value fluctuation changes with the applied vibration are identified in the red dotted line enclosures, indicating the effects of evident vibration during the operation.

To achieve accurate test results, the measuring instrument must be placed on a firm, stable workbench where no vibration affects the measurement from the operating environment; any effects, such as the environment with other machines in operation, must be kept to a minimum, and of course, do not touch the measuring instrument during the operation.

Weight Pulled Horizontally at Straight Angle

The testing environment should offer the operating condition in which the set weight is pulled at a straight angle on a horizontal surface to the force-measuring instrument. Misalignment in the testing setup with the incorrect force transmitted to the force sensor would result in inaccurate measurement results.

As explained in the next section, the orientation of the sample also gives the measurement results. If the weight is not placed at a straight angle, the sample’s orientation may change, affecting the measurement results.

Correct Sample Orientation Placement

Depending on the surface properties of the measuring sample, the sample must be at the correct orientation placement. What may seem indifferent, the placement direction should be correct for specific friction and friction coefficient measurements.

Cautionary Attention for Surface Condition: Differences and Changes

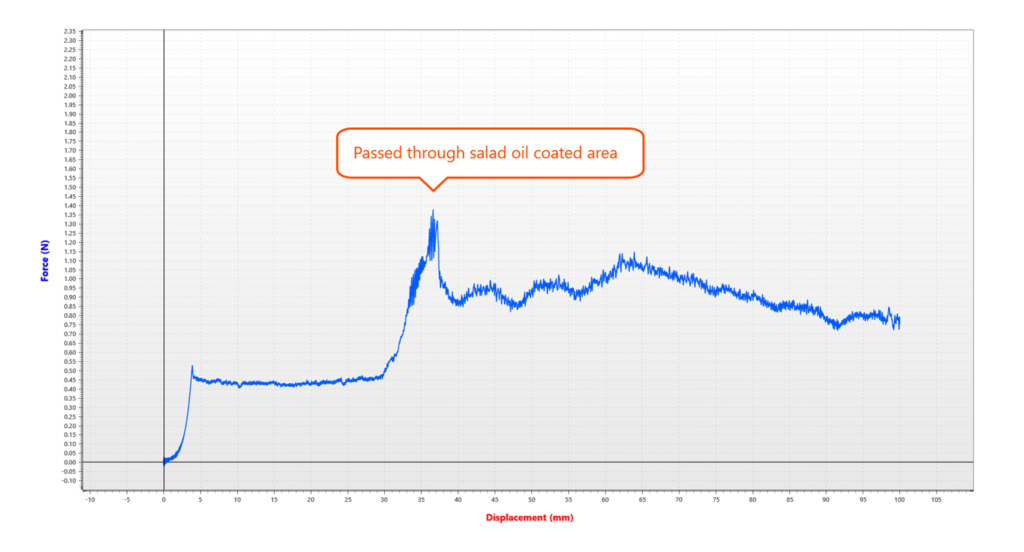

Friction tests are susceptible to the surface condition of the sample. Do not touch the measuring sample surface with your fingers; the measurement surface should be kept clean and free from fingerprints and any moisture. The graph below is the sample force-displacement graph, showing an obvious indication of the surface’s friction changes with the lower half of the sample coated with salad oil in this case.

Also, remember that some influences are difficult to identify through visual confirmation. Unless specified, avoid using the same sample for repeated measurements.

Although not included in the five mentioned points, the environmental condition dramatically impacts the sample’s condition and the test results, in particular, the ambient temperature and the humidity, which may change the characteristics of the sample, hence friction test results.

In this article, we focused on practical key points to help reproducibility improvement in friction tests.

As mentioned earlier, the theoretical friction force is said to be determined by the surface characteristics: friction coefficient and normal force of the object, but it is known that the actual measured value is affected by various individual factors. To perform tests of the required standard for evaluating the physical properties of the sample, the testing condition controls to realize the stable and unified condition to improve reproducibility and accuracy.

Some helpful examples of measurements and case study videos are available on IMADA’s website, including friction testing and friction coefficient measurements explained in this article. Some tests that comply with Standards such as ISO are also available for your reference.