In the previous article, we introduced Compression Strength Testing, which measures the strength when the entire sample is pressed. In this second article, we will introduce the “Bending Test,” which measures the strength against bending (breaking).

In a bending test, a compressive force is applied to the center of a sample supported on both sides, and the required force value for the sample to bend (to break) is measured*1. This test evaluates product strength and material characteristics such as workability. The commonly used test methods are “3-point bending,” “4-point bending,” and “cantilever bending.” According to the application and purposes, it is essential to conduct the tests with the appropriate methods.

The following explains the test methods for each bending test and introduces measurement examples.

*1 In a Cantilever Bending Test, the sample is supported on one side while a compressive force is applied to the other.

3-Point and 4-Point Bending Test

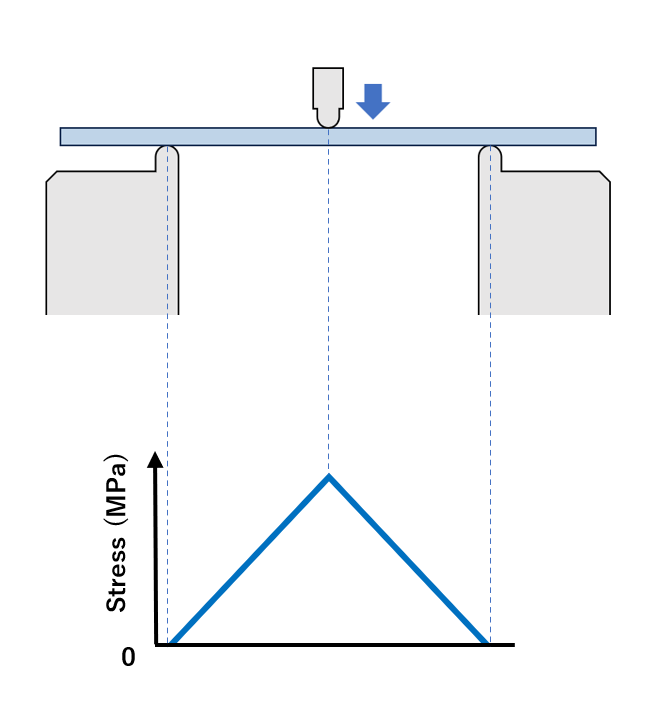

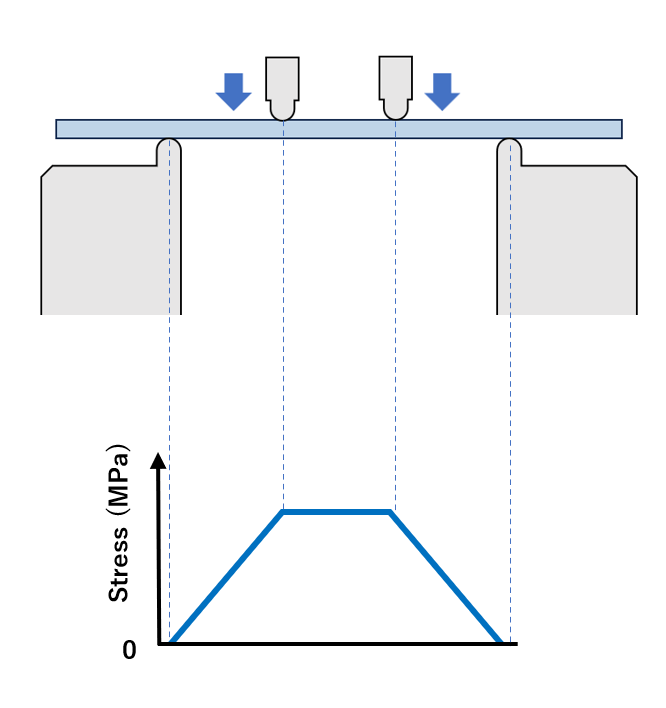

So, in the 3-Point Bending Test, both ends of the sample are supported from below while a force is slowly applied to the center to measure strength. The 3-point means the 2 supporting points and 1 force-applying point. The 4-point means 2 supporting points with 2 force-applying points.

The main difference between the 3-point and the 4-point bending tests is the range where the maximum stress*2 occurs. In a 3-point bending test, maximum stress is localized just below the force-applying point, whereas in a 4-point bending test, maximum stress occurs evenly between the two force-applying points. Therefore, in a 3-point bending strength test, it is considered difficult to obtain accurate test results for some samples with structural inhomogeneity of strength, such as random cracks on the surface, so a 4-point bending test is applied, which enables more reproducible measurements.

*2 Stress is the internal resistance developed by the object to resist the deformation. In the case of a bending test, bending stress occurs inside the sample being bent. In force measurement, the magnitude of the force applied to the object’s surface is measured, but the stress occurs inside the object and is affected by the object form, how to apply the forces etc.

| 3-point Bending Test | 4-point Bending Test |

|---|---|

Stress is concentrated on the force-applying points |  Uniform Stress occurs between the two force-applying points |

While the 4-point bending test is suited for measuring heterogeneous strength samples, some operation conducting disadvantages are challenging, such as being prone to uneven loading due to tilt, etc. The 3-point bending test, which has a more straightforward structure and is simpler to conduct, is commonly applied. In addition, performing the four-point bending test may not be possible for small samples. Also, the compressive force required to generate the same maximum bending stress varies between the 3-point bending test and the 4-point bending test. Obviously, the same test methods must be used to compare the results.

| Measurement Key Points | 3-Point Bending Test | 4-Point Bending Test |

|---|---|---|

| Ease of Operation Setting | ☑ SIMPLE Structure | Prone to Uneven Force |

| Max. Stress Range | Concentrated: – under the force-applying point | Uniform: between the two force-applying points |

| Samples of Heterogeneous Materials | Results: Poor Reproducibility | ☑ Result: High Reproducibility |

| Compressive Force Before Sample Failure | 3-Point < 4-Point | 4-Point > 3-Point |

| Others | Susceptible to force-applying point misalignment | Unsuitable for small samples |

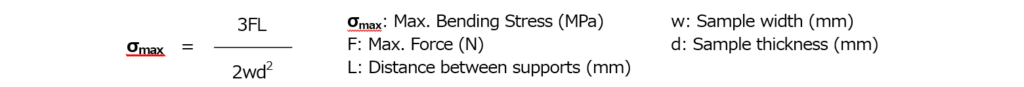

The test results are expressed as a force value (N), and in material testing, calculation of the “Bending Stress (max. Stress)” may often be required. Bending Stress is the resistance generated inside a sample bent. The following is an example of the 3-point bending test of a plate form sample with applied bending force; the bending stress is calculated with the formula below.

Calculating bending stress helps evaluate the bending properties of the structures with the same materials, which are valuable for strength calculations and design.

The evaluation of the sample deformation*3 is also measured additionally. The flexural modulus, an index of resistance to being or ease of bending, is calculated for the material evaluation of stiffness and products from the Bending Stress and deformation.

*3 Deflection (displacement) measurement with a displacement meter / Strain measurement using a strain gauge, etc.

Measurement Examples: 3-point Bending Tests

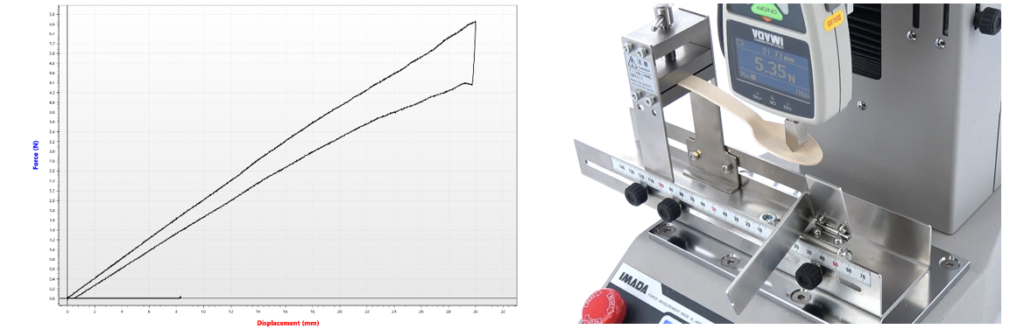

The 3-point bending test for “fine ceramics” and “paper straws” below are typical examples of the widely practiced material property evaluation and strength measurements of the finished products.

3-point Bending Strength Test: Fine Ceramics

In fine Ceramics, 3 and 4-point bending tests are typical for material properties evaluation in quality control. e.g., JIS R 1601: 2008 “Testing method for flexural strength (modulus of rupture) of fine ceramics at room temperature” specifies 3 and 4-point bending test conditions as the test methods for calculating bending strength (bending Stress), and JIS R 1602: 1995 “Testing methods for elastic modulus of fine ceramics” is for calculating bending modulus.

Not limited to materials such as fine ceramics, the standards for material properties evaluation specify details: the sample size (width, thickness, length) and shape, the distance between supports, and the shapes of the support and force-applying point parts, etc. Although there are no regulations and restrictions for complying with the standards, conducting tests that follow the standards with high recognition in the industry helps increase quality reliability.

3-point Bending Test: Paper Straws

3-point bending tests are recommended for long, thin products: straws, pencils, and toothbrushes. There are limited industry standards for these products, and individual manufacturers conduct tests to maintain the level of quality and how they are used for safety, such as in consumer products and the food industry: e.g., the force section of the sample is set off-center, depending on the function and usage. Setting testing conditions for reproducible tests is essential to ensuring repeatability in result comparisons.

>>Click for the video of 3-Point Bending Test of Paper Straw

Cantilever Bending Test

The cantilever bending test is conducted in which a force is applied to a sample with only one side fixed to the fixture to evaluate the sample’s bending characteristics. It is not uncommon for products to which concentrated force is applied while the opposite side fixed, such as “syringe needles,” “spoons (cutlery),” and “fishing rods.”

In cases like the above, strength measurement and material property evaluation will be conducted using a cantilever bending test rather than a 3-point or 4-point bending test.

With a cantilever bending test, the Bending Stress (MPa) test can be conducted from the distance from the support point to the force-applying point, the compressive force, and the cross-sectional area of the sample. However, compared to 3 and 4-point Bending Tests, Cantilever Bending Tests are used for strength measurement of products, and therefore, the bending Stress is not usually calculated.

When measuring product strength, determining the supporting and force positions according to the usage is required; however, depending on the positions, the apparent differences are identified in the test results.

Cantilever bending test for cutlery

More and more plastic cutlery is being replaced by paper and wood-based products, and product strength management for safety is essential, especially for products with newly introduced materials. The Cantilever bending test is one of the most straightforward strength evaluation tests for quality assurance.

>>Click for the video of Cantilever Bending Test of Cutlery

Summary

This article introduced the Bending Tests as part of the Compression Test series. The Bending tests utilize various methods and, in many cases, involve Bending Stress and Elasticity Module calculations. This versatility allows the tests to meet multiple demands. There are other compression tests, such as operability tests and texture measurements. In the following article, we will be introducing an operability test. There are Videos demonstrating some practical reference examples of compression tests, including the bending tests, available on the IMADA website. Please take this opportunity to explore.