Compression test to evaluate strength and functionality

The compression tests measure the force to check the strength and operability by applying forces in the compressing, pushing, and crushing directions to a sample. The purpose of compression tests is for compressive strength check and functionality evaluation.

- Compressive strength check: Measurement of the strength itself, which is the physical property of the sample.

- Functionality evaluation: Evaluate the test results based on indicators other than strength, such as safety, operability, and protection.

The purpose of the test introduced in this article is generally performed for compressive strength checks. The physical property strength of the sample is confirmed by measuring how much compression force is required to the level to destroy (crash, burst, deform, buckle, etc.) and whether it can withstand a generally recognized standard compressing force.

Often, compression strength tests are performed on packaging and containers such as pouches and PET bottles from the perspective of evaluating the functional requirements, such as durability and airtightness, etc.

It is also applied for various parts, materials, and functionality evaluation. For example, compression strength tests are used to check the compression resistance of PET/plastic bottles for their durability to withstand understanding their durability during transportation and storage. Also, Manufacturers seek to minimize costs by lightweighting bottles – using just enough material to meet minimum strength requirements, which can withstand filling and meet appropriate functionality, and how easily they are handled to squash in case of discards.

How to conduct compression strength tests

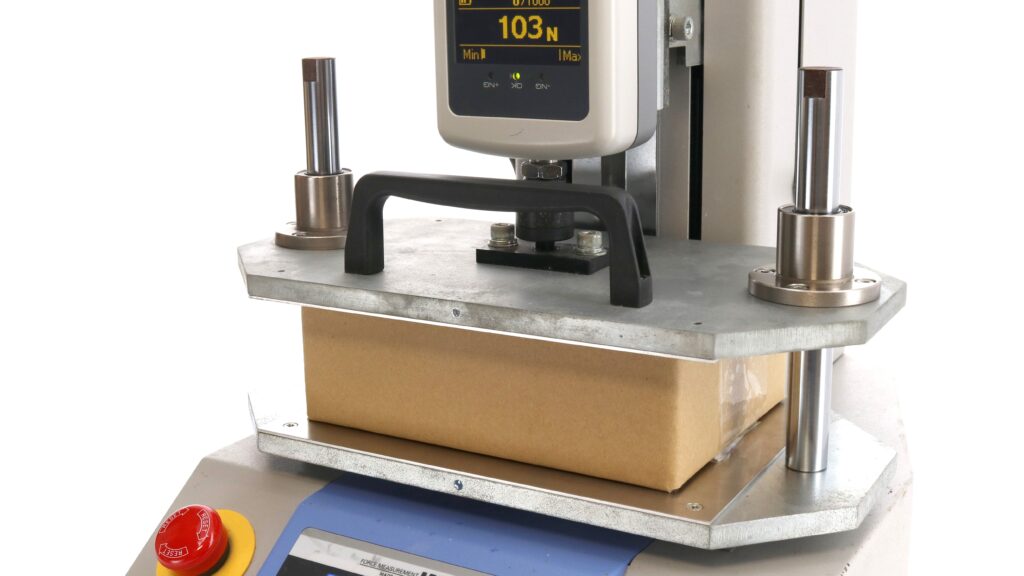

A compression strength test, known as a Top Load Test, requires the environment with the mechanism to apply the Load directly from above to the sample. Therefore, measuring instruments (such as a force gauge) must compress the sample efficiently to conduct this test.

If a large force is not required to compress the sample, the test can be conducted by holding the measuring instrument by hand and applying forces to the sample. Suppose a test requires a larger force value or higher reproducibility. In that case, the test can be performed with a combination of the test stand and force gauge installment to configure a compression tester.

If there is no specific reason to know the strength of the particular section, it is common to use a jig or other tool to apply force to the entire sample for strength confirmation. If the compression surface of the jig is narrower than the sample, the contact area and contact points affect the test results.

The compression speed also affects the test result. From the test results comparisons, for judging the pass/fail, there must be no deviation in the test conditions.

The compression strength test (destructive test) results may require a conversion from the compression force (N) displayed on the force gauge to pressure (Pa) per unit area. Pressure is calculated from the compression force and contact area using the following formula:

* Pa is the force (N/m2) applied per 1 m2. Other units, such as N/mm2, are also used.

* N (Newton) is a unit of force. 1N is equivalent to a weight of about 1.02 kg on the surface.

Destructive and durability tests

Compression strength tests are generally classified into “Destructive” and “Durability tests“. For the Destructive tests, apply force until the sample is destroyed (crash, burst, deformed, buckled, etc.) and confirm the sample destroying force.

For the Durability Tests, apply a certain amount of force for a certain period to confirm if the sample can withstand the force without being destroyed and losing its original state.

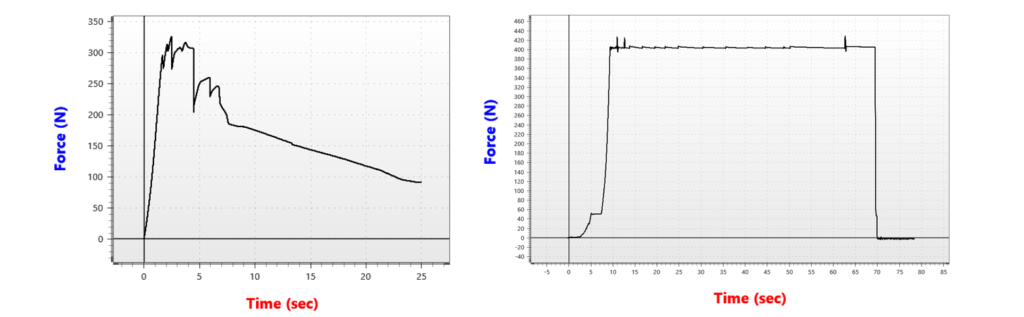

Vertical axis: Force value / Horizontal axis: Time

The force transition in the Destructive tests shows that the sharp increase in the force value leads to sample destruction, following a decrease in the force value; the sample’s compressive strength is the point of destruction identified from the test result.

In some test cases, the graph is unadopted, and the compressive strength is confirmed using only the peak value*1, where the displacement and the force are measured simultaneously and confirm the amount of compression at which destruction occurs.

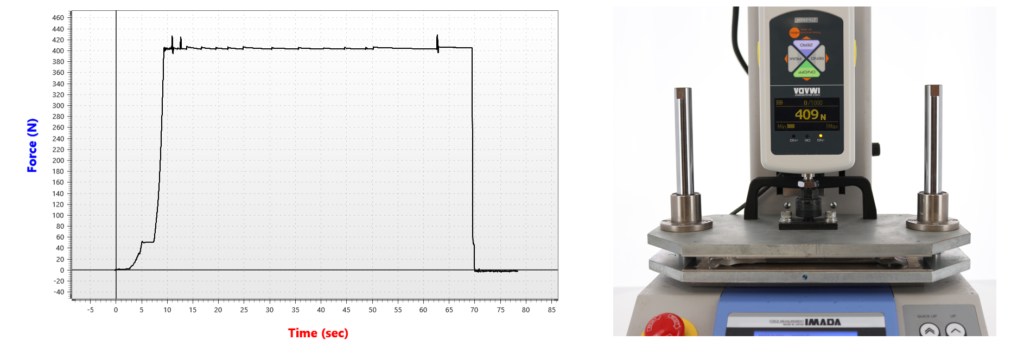

In the Durability tests, the advance determination of the force value and time is essential; therefore, in most cases, the tests are conducted by in-house standards and specifications (JIS, ISO, industry standards, etc.). Instead of adapting measuring instruments, placing a weight above the specified Load to measure the sample is possible, ensuring that the application load is conducted evenly across the entire sample.

A repeated Durability Test is also conducted in which a force above the specified value is repeatedly applied to the sample to check if the sample can withstand the force without destruction.

*1 Peak value = the maximum force value in the measurement.

In many cases, the force value at which destruction occurs is the maximum force value. Please note that there may be cases where partial destruction or immediate bottoming out of the force value may rise again even after destruction.

Examples of compression strength tests

Compression strength tests are essential quality assessment tests in the packaging industry for evaluating the protective performance of the content. This article introduces the two standard tests in the packaging industry: – “Compression Durability Test for Retort Pouches” and the “Top Load Test for PET Bottles,” for your reference.

Compression Durability Test for Retort Pouche Packaging

The compression durability test checks the retort pouch’s sealing performances to check the pouch’s content’s damage or leakage level when a specific force is applied for a certain period. The standard force value and the time are suggested according to industry standards or JIS standards. For example, JIS Z 0238:1998 Testing methods for heat-sealed flexible packages containers “10. Compression resistance test” specifies that the pouch should be compressed for one minute with a load determined by the contents.

The Load-Time Graph confirms that the specified load value was applied for the specified time.

Since retort pouches are flexible containers, the force application must be evenly distributed entirely over the container surfaces and the content. It must also be evenly compressed for accurate test results. It is also necessary to compress the entire container so that the force can be firmly received in full, including the pouch’s heat-sealed area for durability and content protection.

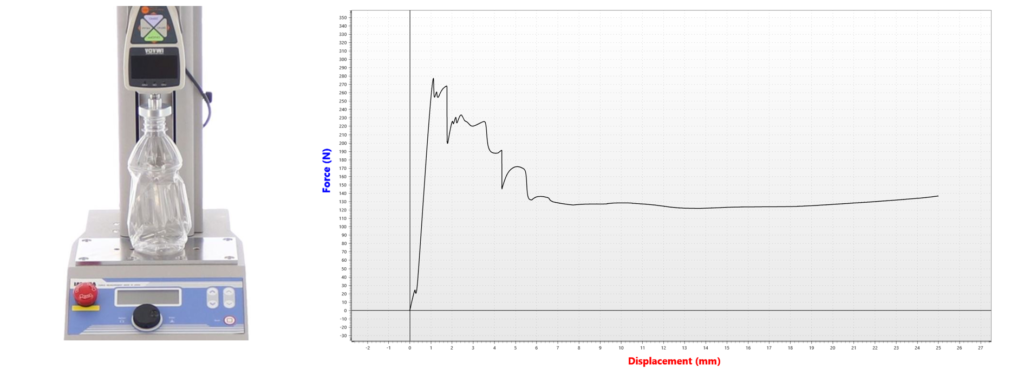

Top load test for PET bottles

In the PET bottles quality control, the top load tests (compression strength tests) are some of the standard tests performed. Regarding content protection, PET bottles must withstand a certain amount of compression resistance. The recent developments in PET bottles are for environmental and resource conservation and consumer convenience, resulting in lower costs. The top load test is adopted to evaluate the convenience and the superiority from the above perspectives.

It is standard practice in the industry to measure the displacement in addition to the force at the point where the buckling occurs.

>>Click for the video of the PET Bottles Top Load Test

Summary

This time, we focused on the “compression strength test” among compression tests. In addition to the ones we introduced this time, there are many other compression test types, such as bending tests, operability tests, and hardness measurements. Next time, we will focus on the “bending test,” often used in material tests. IMADA’s website has many videos of compression test measurement examples. Please take this opportunity to check them out.