Malaysia is one of the primary producers of natural rubber, and the country is home to many of the world’s largest glove makers.

For the second User Visit, we had the opportunity to explore the R&D Testing Lab, Ansell Global Trading Center (Malaysia) Sdn., Bhd. in Malaysia. One of our focuses was understanding the role and contribution of force measurements in their product quality control processes.

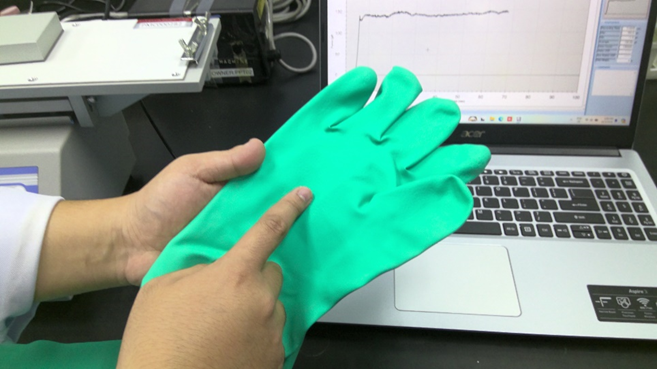

Glove testing involves a series of mechanical material tests and one of which is force measurements. These evaluations are crucial for determining the gloves’ grip and ease of donning, as well as for ensuring their overall quality and safety. During this visit, the friction test process was demonstrated by the Ansell R&D Testing lab to illustrate how the frictional properties of the gloves is assessed.

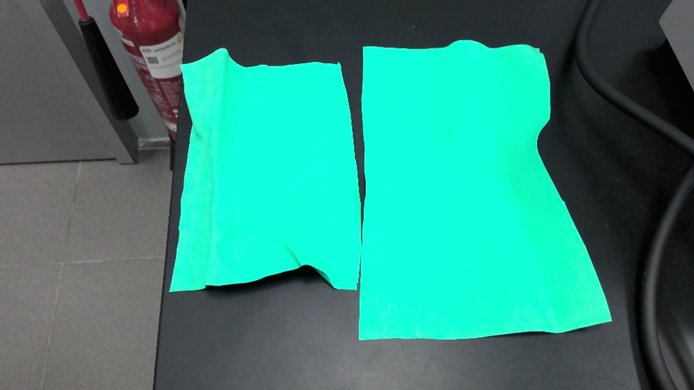

Various friction tests, involving different glove surface types, were conducted. During testing, samples were cut from the gloves.

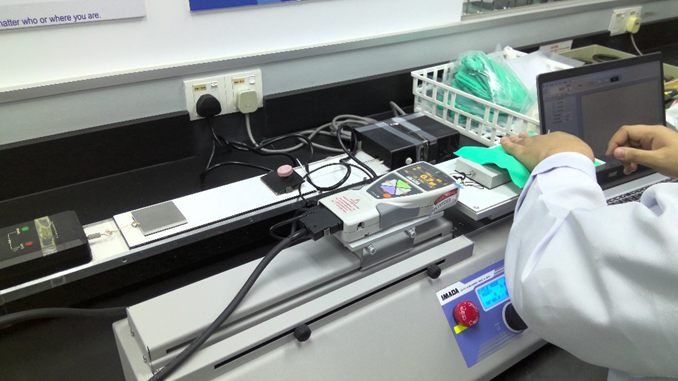

The samples were mounted onto the worktable of the friction tester.

The sled weight was placed onto the sample and the coefficient of friction (COF) was measured by pulling the sled weight across the test sample.

Using the method described above, the rubber gloves’ kinetic friction coefficient was checked to determine whether it was within the standard value of their requirement.

A friction test measures the coefficient of friction between two materials.

The test results are affected by the weight in relation to the force value applied vertically, the speed at which the weight is pulled horizontally, and the roughness and other conditions of the contact surfaces of the two samples.

The Ansell R&D Testing Lab includes the IMADA force measuring instrument among the various instruments used by the lab to evaluate the coefficient of friction properties of gloves. The lab is currently conducting method validation and comparing measurement data to ensure the results meet in-house standards.

The experience was not only a valuable opportunity to learn about the diverse quality characteristics of rubber gloves, but also a chance to learn about the importance of maintaining high manufacturing standards for product that protect wearers in medical, industrial, and other fields.

In addition, we were grateful that IMADA’s measuring instruments were chosen to take part in the quality control process for maintaining the high-quality standard and at the same time, strongly reminded of the heavy responsibility and importance of maintaining high quality standards of our measuring instruments.

Thank you very much to Ansell Global Trading Center (Malaysia) Sdn. Bhd. for a fascinating introduction to the industry and the valuable opportunity for our experiences.