Q:In compression test, can measurement values change depending on the attachment? What should we consider when choosing the optimal one from various types of attachments?

A:In force measurement, an attachment refers to a jig that is used by attaching to the measuring shaft of a force gauge or a test stand. Since the force is transmitted to the load cell through the attachment, the shape of the attachment, which defines how the force is applied, has a significant impact on the measured value. Other factors such as attachment material and slipperiness may also affect measurements.

In force measurement, not only attachments, but test conditions such as pushing amount and measurement speed can also affect the force value. In this case, we unified these test conditions and verified how the measurement values change due to the difference in the shape of the attachments. We perform a compression test of 2 types of gummies using various shapes of attachments with the same test machine and measurement conditions (pushing amount, measurement speed).

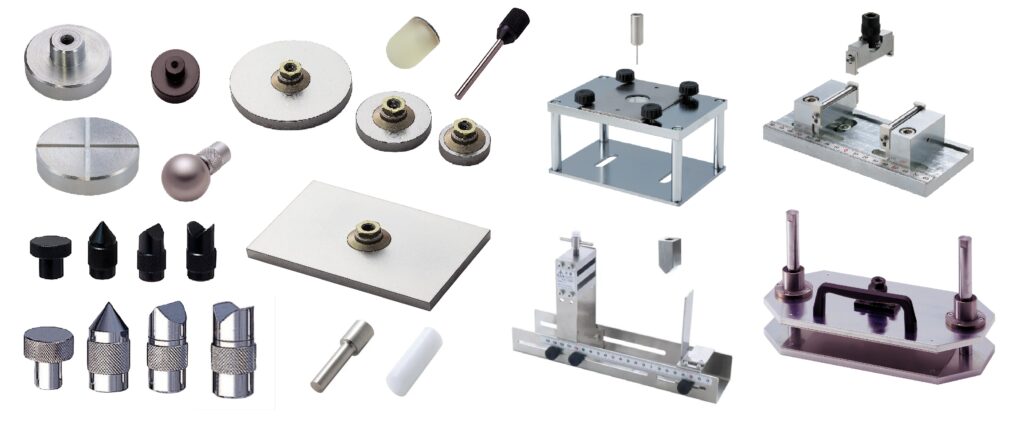

| The attachments options for the comparison test |  Disk Probe(Φ20mm)Since it can receive a load over a wide area, this attachment is also used for the viscosity test of semi-solid sample aside from compression test. |  Sphere Probe This attachment can apply force at a point. It can compress and deform the sample. Suitable to measure the texture of food when chewing in the mouth. |

Wedge Probe Use this attachment to measure the hardness of samples when the push and cut them with a sharp edge. Able to measure the hardness of the sample bitten off with front teeth by setting the probe both upward and downward. |  Conical Probe Since the tip of this attachment is sharp, it is suitable to measure the force when a sample is cut through or penetrated. |  Cylindrical Probe(Φ5mm) Using this attachment to measure the force when pressing the sample on some part to push out the content or to crush the part. |

The following table shows the maximum force value (N) when compressed to a height of 5 mm above the table.

| Attachment shape | Gummy A (width:18.2㎜ thickness:9.9㎜) | Gummy B (width:18.2㎜ thickness:13.4㎜) | |

| Disk Probe | 27.2 | 69.26 |

| Sphere Probe | 6.68 | 23.40 | |

| Wedge Probe | 4.98 | 20.80 | |

| Conical Probe | 4.52 | 13.40 | |

| Cylindrical Probe | 1.48 | 5.46 |

Average value of 5 samples for each attachment

The force values were in order of attachment contact area from the largest (disk shape) to the smallest (conical shape). The force values for the disk shape were particularly large, while the other values were much smaller. This is because the larger the contact area is, the greater force value is required to deform the sample, since the overall compression force is distributed over the entire area and the force per unit area gets smaller. Furthermore, the way the sample deforms or is penetrated varies depending on the contact area.

The above results proved that even when measuring the same sample under the same conditions, different attachment shapes can change the contact area and force values.

As we have seen, different attachments produce different measured force values even for the same measurement. Next, we will explain how to select the most appropriate attachment depending on the test purpose. First, the ideal attachment shape is one that can apply forces on the sample similarly in a actual usage. Below are some common compression test attachment shapes and examples of suitable usage.

| Picture | Shape | Usage |

| Disk shape | Circular or flat shape, suitable for compression testing by pressing on a surface. | |

| Conical shape | The conical attachment is used to measure the force that penetrates the sample. | |

| A shape | A mountain-shaped jig is used to measure the force required to cut the sample. |

| V shape | The attachment with a V-shaped groove is ideal for measuring samples that tend to roll. | |

| Pin shape/ Cylindrical shape | Using these attachments to measure the force applied to small parts or a localized area. | |

| Sphere shape | Using these attachments to measure the force applied to small parts or a localized area. | |

| Shapes that replicate the sensation of pressing with a finger | A silicone attachment is used to quantify the sensation of finger pressing. |

In addition to shape, the following points should be considered when choosing an attachment.

1. Maximum Capacity

Each attachment has a maximum tolerance load value. We recommend an attachment with a slightly higher capacity than the expected force value.

2. Attachment Weight

Since the weight of the attachment itself is also recognized as a load for the force gauge, it is necessary to select an attachment whose weight is less than 10% of the force gauge maximum capacity.

3. Compliance with Standards and Industry Norms

If you need to comply with JIS, ISO, or other standards, you must choose the attachment that fit to the standards requirements.

Thus, the selection of an attachment requires consideration of many factors, including the shape and weight of the attachment. Selecting the most appropriate attachment for the test purpose helps obtain reliable measurement results. In any case, it is important to unify the conditions of the test, including attachments. Please click here to contact us for further discussion regarding attachment selection.

Regarding how to choose grip fixtures commonly used for tensile testing, please look at this page.