Traceable ISO/IEC 17025 accredited calibration is preferred, and the demand is increasing as it is recognized worldwide as an International Standard and performed by accredited laboratories. The standard defines the requirements for the competence of test and calibration laboratories and measures the uncertainties of calibration results.

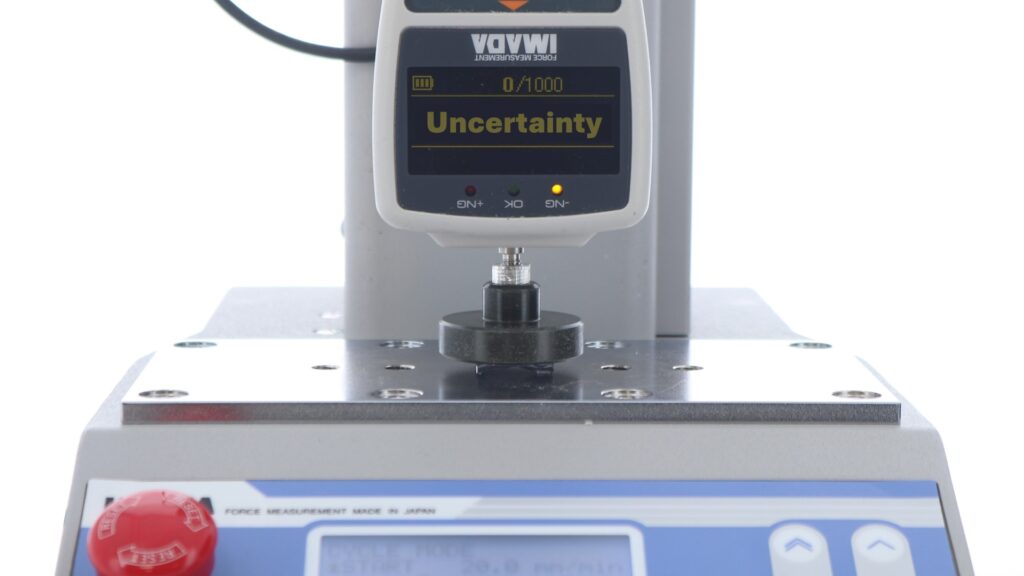

Although Uncertainty has been introduced as an index to express the ambiguity of measurement results, the term Uncertainty in calibration has yet to be widely recognized, and we wish to explain the theory behind it in this Article.

What is Uncertainty in Calibration?

Uncertainty in calibration is a numerical index of the variation in calibration results (reading of the indicated value) when the same calibration procedure is repeated.

When calibrating a force-measuring instrument, a reference force is applied to the instrument, and the indicated value is read. Calibration is performed with the utmost care, but the reading results will vary due to a range of factors, even if the same procedure is used.

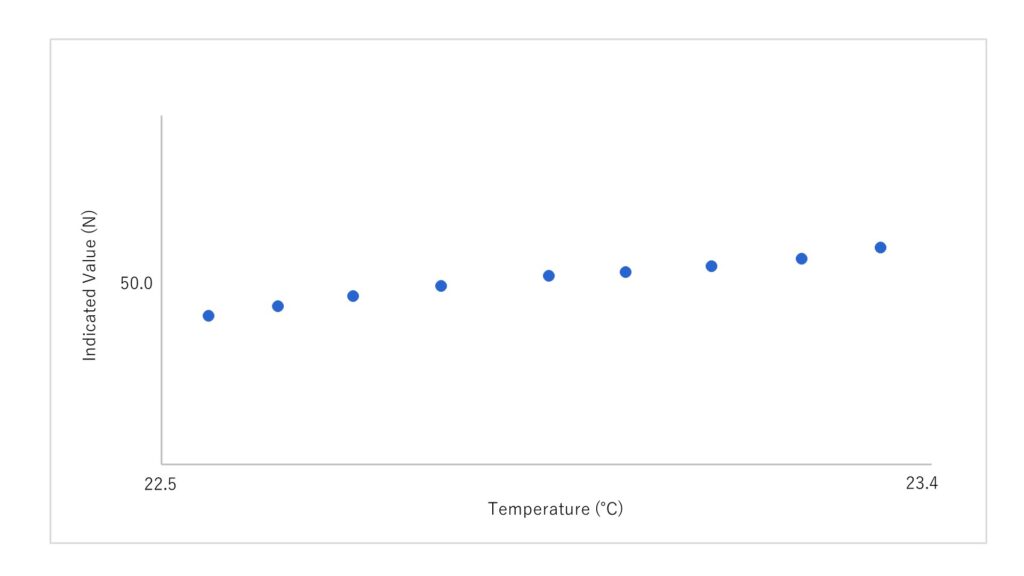

The calibration environment (temperature, humidity, etc.) is one factor that can cause variations in calibration results.

For example, if the calibration environment is at 23℃, a thermometer with 1℃ increments may show 23℃. The displayed temperature, with the general rounding of the number, means that the actual ambient temperature is within the range of 22.5℃ and 23.4 ℃, resulting in the potential variation in the actual ambient temperature. (not considering any potential rounding error beyond the nearest whole number)

Although fractional, the temperature differences affect the values indicated on the instrument.

This means that if a thermometer that displays up to the first decimal place would show 23.0℃, the potential error is reduced to within ±0.1℃, but the actual ambient temperature is within the range of 22.95 and 23.04℃. (not considering any potential rounding error beyond the nearest whole number)

*1 In reality, ±0.5℃ is the fractional temperature difference, and minimal effect is caused by the measuring instrument from the temperature alone; Hence, the effect to the calibration result (reading value) is small. When the various accumulated factors are combined, Variations in calibration results are seen.

As stated above, if a calibration results from an environment of 23℃, it is doubtful whether it is the result of calibration at “precisely 23℃.” Uncertainty is an index that quantifies this doubt, which is vagueness. Uncertainty is applied, but quantifying the doubt makes it possible to interpret a small uncertainty as high reliability in calibration results.

Uncertainty factors are not limited to the calibration environment. The Uncertainty in the ISO/IEC17025 calibration certificate is calculated by combining various uncertainty components. *2

*2 In ISO/IEC 17025 accredited calibration certificates, the Uncertainty due to various factors is summarized and expressed as the calibration results between calibration result XXN ± XX% with a probability of inclusion of △△% (relative expanded Uncertainty). For details, please refer to ISO/IEC Guide 98-3:2008 Uncertainty of measurement — Part 3: Guide to the expression of Uncertainty in measurement (GUM:1995). It is impossible to achieve a perfect measurement without variation or bias, so the actual value cannot be obtained and can only be known as an estimated value with a reliable interval.

The reasons for using Uncertainty?

The expression Uncertainty in Measurement: Guide to the Expression of Uncertainty in Measurement (GUM) was published by the International Organization for Standardization (ISO) in 1993 at the urging of the International Committee for Weights and Measures (CIPM). In addition to ISO, seven international organizations, including the Bureau International des Poids et Measures (BIPM), were involved in the definition process.

The purpose of Uncertainty is to enable the evaluation of the reliability of measurement results and to reach international agreement on evaluation methods and expressions.

Before the publication of GUM, there were methods for evaluating the reliability of measurement results. However, these evaluation methods were not agreed upon by countries or regions.With the advent of Uncertainty, it is now possible to evaluate the reliability of measurement results without confirming the evaluation method.

The International Vocabulary of Metrology-Basic and general concepts and associated terms (VIM) mentions Uncertainty as a factor in calibrating traceability.

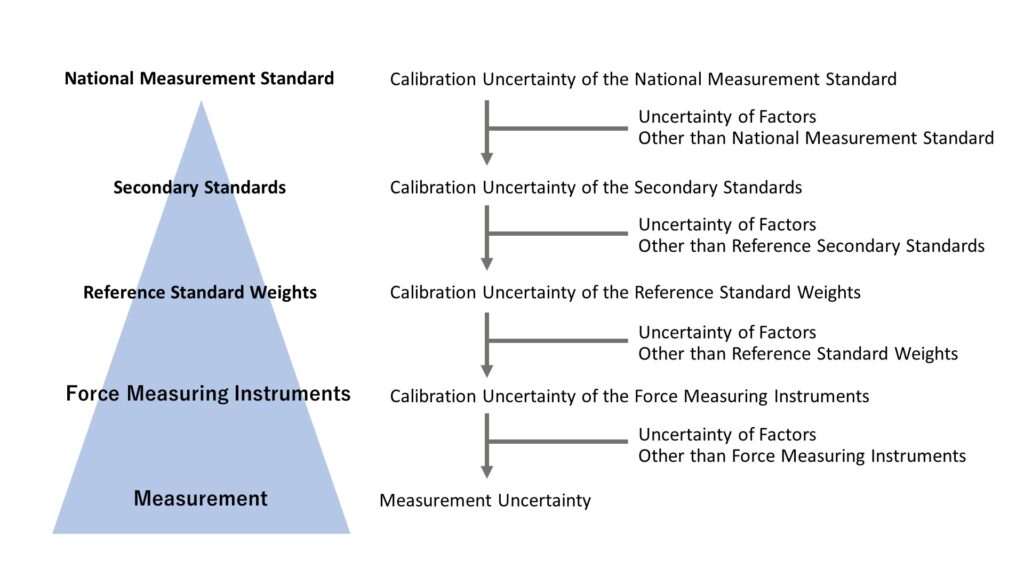

One factor contributing to calibration uncertainty is the standard’s calibration uncertainty. For example, the reference standard weights used for calibration are calibrated against their nominal values. As mentioned earlier, perfect calibration without any ambiguity is not realistic. In other words, there is always some uncertainty in the calibration results of the reference standard weights. *3 This means that the calibration uncertainty of the standards must be considered when calculating the calibration uncertainty.

A standard’s calibration uncertainty includes its parent standard’s calibration uncertainty. Therefore, to calculate the calibration uncertainty, one must trace it back through the chain of calibration of the RMs and eventually to the national measurement standards. This can be translated as calibration uncertainty, expressed as no break in the calibration chain up to the national measurement standard (traceable).

*3 Tolerance at the time of calibration of the standard (for example, a calibration result of up to 50N±0.1% is considered pass, and a nominal value of 50N is given) is also calculated as the Uncertainty of calibration of the standard.

Benefits of small uncertainties

Once again, calibration uncertainty is a numerical index of calibration results’ variability, doubt, and ambiguity. Small calibration uncertainty brings the following benefits:

- Contributes to reducing measurement uncertainty when using a measuring instrument for actual measurements. (The Uncertainty of a measuring instrument’s calibration is transferred to the Uncertainty of the measurement, but various new factors create new uncertainties during actual measurements.)

- Reduces deviations in results for each regular calibration. High reproducibility of calibration results allows you to identify any abnormalities in the results with certainty. Also, by adjusting the indicated value, the standard’s value can be approached with a high degree of confidence.

Currently, there are only limited situations in which Uncertainty is required to be presented for measurement results, such as quality control. However, with the increasing demand for ISO/IEC 17025 accredited calibration, there may be cases in the future where the Uncertainty of measurement results will need to be controlled. If you have a choice of calibration service providers, select a calibration with little Uncertainty from the current stage.

It is important to note that “small calibration uncertainty” indicates the reproducibility of the calibration results and does not directly translate to “high quality of the calibrated measuring instrument *4”.

For example, if there is a significant difference between the reading and the standard’s value due to calibration, even if the calibration uncertainty is low, the instrument is not appropriate as a measuring instrument. (For example, a calibration using a reference standard weight of 50 N with a small calibration uncertainty result in a calibration result of 56 N.)

Regardless of the calibration uncertainty, if the difference between the calibration result and the standard value is significant, it is essential to adjust the measuring instrument to bring the calibration results closer to the values of the standard device.

*4 Here, this refers to the fact that the measurement result is close to the standard’s numerical value (the nominal value of the standard or the measurement result by the standard).

Summary

We have introduced calibration uncertainty in this article.

In the world of measurement, the understanding and importance of Uncertainty and Traceability are becoming increasingly notable. Accurate measurement evaluation and reliability are essential with the high demand for internationally recognized ISO/IEC 17025 accredited calibration.

IMADA provides ISO/IEC17025 calibration for IMADA products and is constantly working towards reducing Calibration Uncertainty. The differences between the general and ISO/IEC17025 calibrations are explained in the previous Article: Basic Knowledge of Force Gauge Calibration “General Calibration, Factory Calibration, and ISO/IEC17025 Accredited Calibration”