Sushi is one of Japan’s representative soul foods.

The Sushi consists of fresh and flavorful seafood carefully prepared and served with dazzling vinegar-flavored rice that complements the best harmony, backed by solid artisan techniques and skills cultivated through rigorous training and many years of experience.

The presentation and the delicate flavor are the testaments to the skill of Sushi Chefs.

Some of you may have heard that a Sushi Ball (a.k.a Shari-dama) made by an expert contains air pockets and is unraveled when placed in the mouth. The texture of the delicious Sushi Ball is firm enough not to fall apart when picked with chopsticks and the fingertips but loosens when pressed with the tongue, an essential element of what high-quality Sushi means.

Although I currently work for a manufacturer of force measurement devices in Japan. I experienced learning to be a Sushi Chef XX years ago, a rare skill for my new challenge at the time, before moving abroad.

This memory flushed back into my head for this idea… naturally.

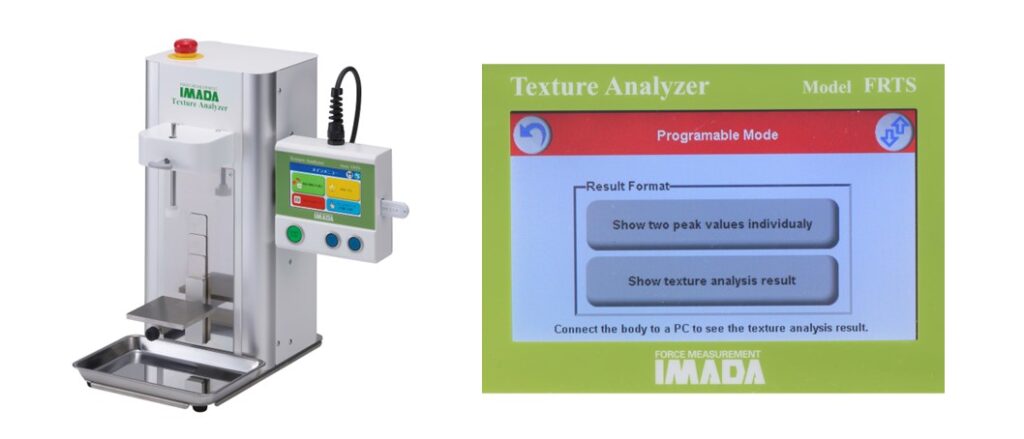

Our Texture Analyzer FRTS may find the air pocket in sushi balls!

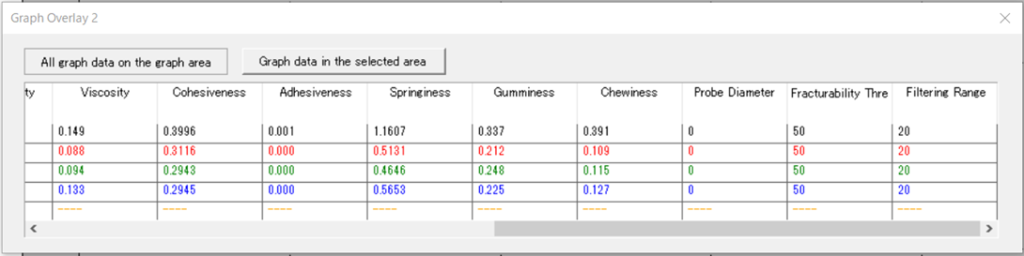

The Texture Profile Analysis function in the FRTS can evaluate the food texture, the softness, stickiness, and adhesiveness in the numerical values. One of the parameters is “fracturability,” expressed as the force value at which the food begins to crumble, and thus I guessed the presence or the absence of air pocket may be measured.

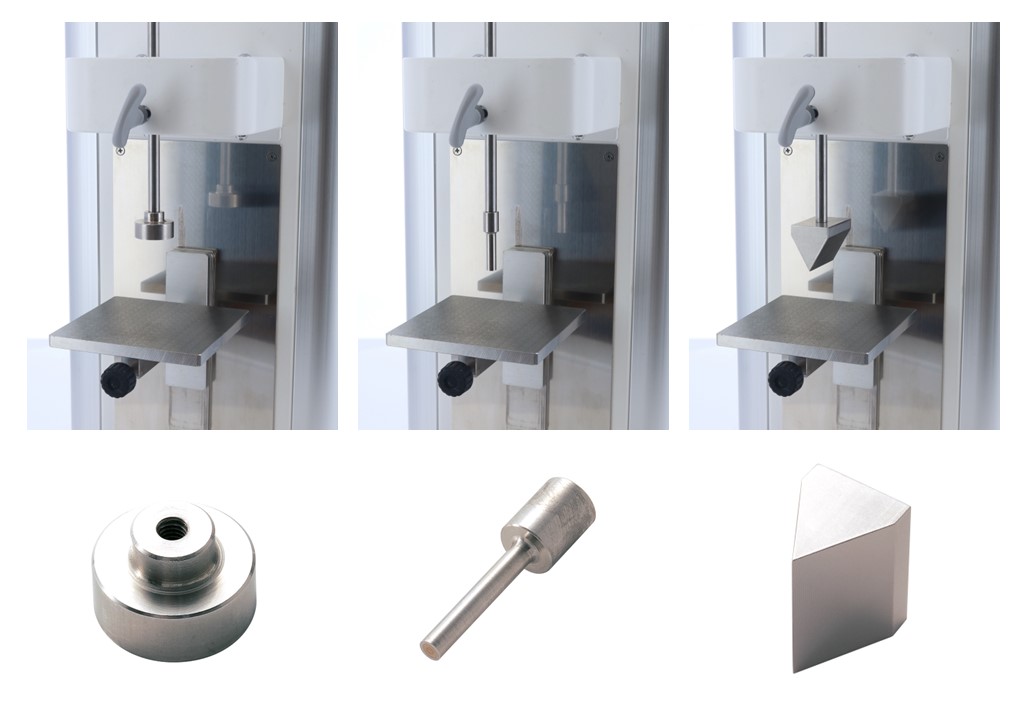

The concern is the different values shown in the result. The value of the air pocket presence would be extremely subtle, and the three different types of probes with various contact points to investigate if the load cell can detect the minor differences.

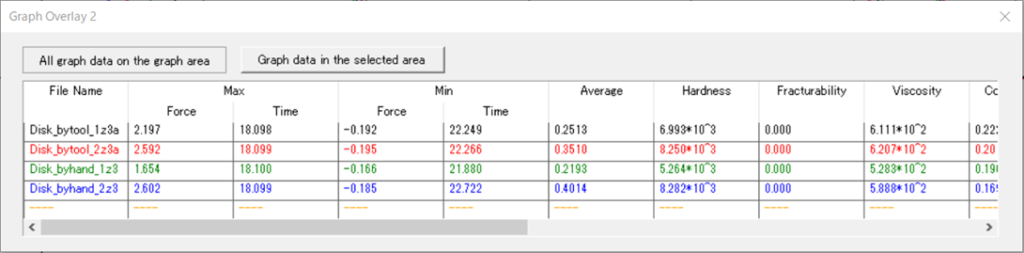

Prepared Two types of Sushi Balls for the measurement: one made with an easy-Sushi Ball maker, standard inexpensive but popular product that anyone can easily make at home, and the other made by myself, actually doing this for the first time in XX years.

OK, not precisely the experienced solid artisan Sushi Chef techniques and skills, but this is how it goes for now. The high-end Sushi delivery for this challenge would be a little too costly.

The Sushi rice was prepared using the instant Sushi rice ingredient vinegar with the ready-to-eat boiled rice I had purchased. Of course, our office has no proper cooking facility, so there is no choice but to mix the Sushi rice in an inexpensive stainless-steel bowl, which does not absorb the excess moisture from the Sushi rice preparation process. The water from the Sushi rice appears at the bottom of the bowl, which is not ideal.

Using Sushi specialized cooking utensils professionals use plays an essential role in how the food tastes.

Proceeded with four measurements, each with three different probes.

The Sushi Ball was made using an easy-to-do Sushi Sushi Ball mold, and as for the other two, I hand-rolled by myself from the old hand-feel memories and the training experiences from the Sushi School.

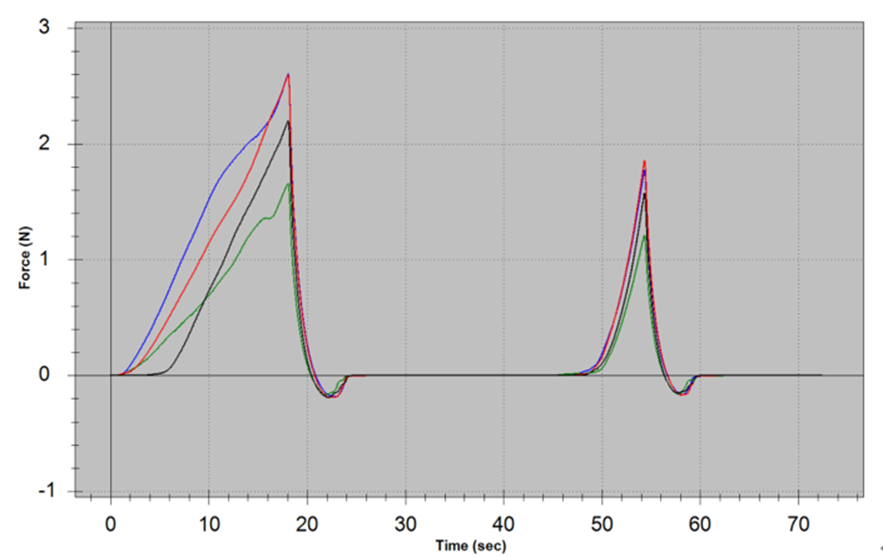

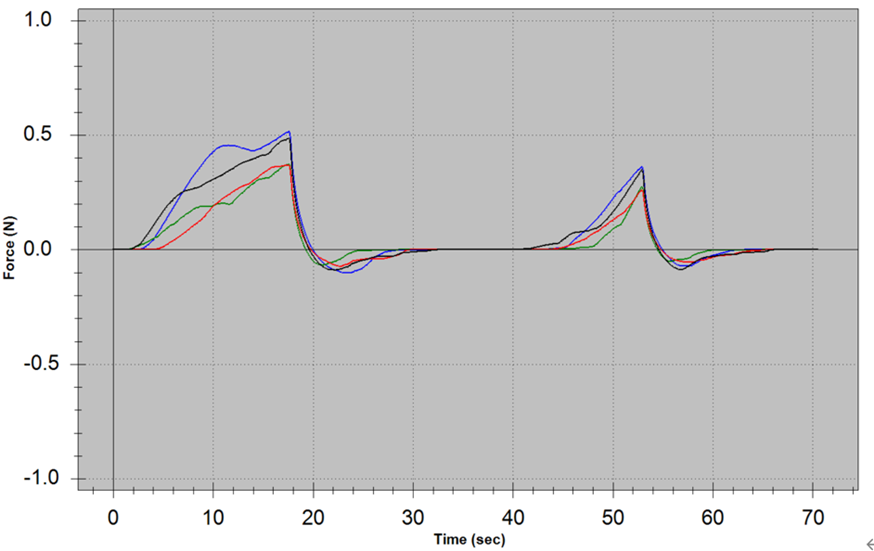

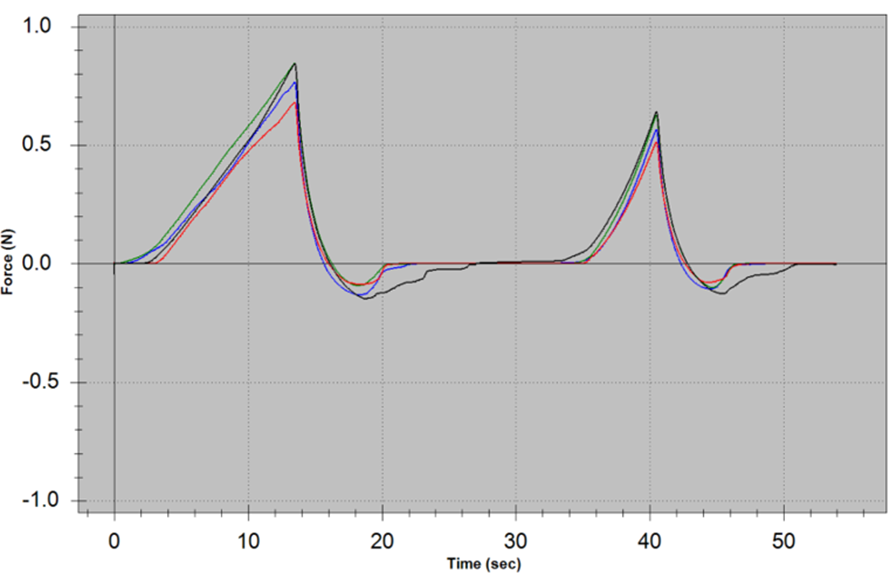

The Sushi Balls prepared were pressed twice per time, and the texture was calculated from the data obtained. If the probe pushed detected the air pocket, and if that is the time when the force value drops once before, that is the time when the fracturabiliy is detected.

(Disk Probe)

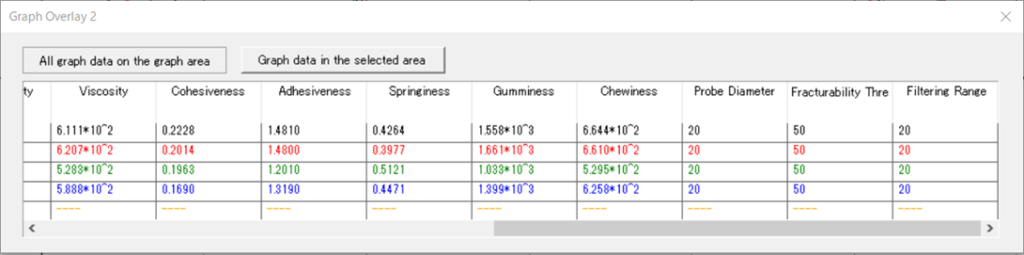

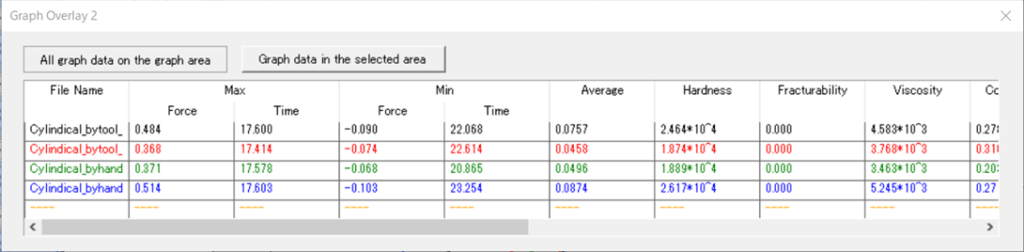

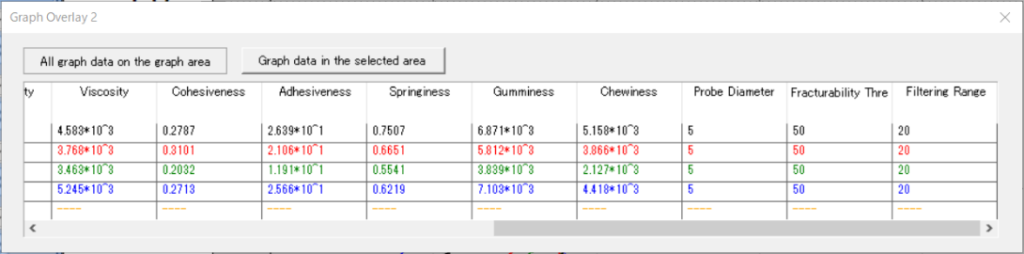

(Cylindrical probe)

(Wedge probe)

Oh!!! Where is the ” fracturability” value? No show?

The fracturability threshold (50digit, equivalent to 0.05N in this tester) may be too large.

Also, I just remembered that I should have included the area of the wedge probe.

Luckily, other data were obtained, so I checked the graphs and other data. The drop in the force value before the peak was barely visible on the charts. Only when the cylindrical probe was used to push the Sushi Ball held by the second hand but lacking in reproducibility.

Even with the disk probe, there is a time when the tilt slows drop, and I wonder if that is where the air pocket layer is? The force increase with the Wedge Probe is almost straight to the Peak Value. Seemingly, the sharp edge is unsuitable for this detection.

In addition to the slope of the graph, there are differences in force values depending on the probe. Considering the degree of contact with the tongue when put in the mouth, the contact area and load value are about the same as those of the disk probe.

In the first place, it was necessary to set an appropriate threshold value to detect fracturability, but it is the inexperienced area as to what value should be set. Would it be better to measure croissants, pies, or other samples with an air layer and take threshold data as well?

The Sushi Ball pressed from the bottom side may be more accurate if you think about eating Sushi.

However, I am from the sales side. Could I come up with a better measurement method?

Considering it seriously, compelling support from the wisdom of the company’s engineers with immense force measurement experience is a must.

So, I went to my Boss to report the experiment results and the conclusion…

Boss: “If we can detect air pockets, I think it will lead to a new force measurement solution.

Please continue with a perspective to product development☺.”

My Boss sounded enthusiastic (not exactly how I expected) and agreed to continue the experiment.

Meaning an excellent result expected! I had to learn to negotiate equally with the in-house fellow force measurement experts!

I am now in the middle of experiencing the responsibilities and pressure of those involved in product development.

It is now my absolute mission to discover the importance of the air pocket in Sushi Balls!

As a team member in the Force measurement industry with experiences in the food and beverages industry and the Sushi Lover, application of my knowledge of food analysis to enhance deliciousness through Force measurement may have been my destiny. First, start with consulting fellow engineers. (Continued)