Q:

When measuring the opening force of a package using a digital force gauge, can we measure manually by hand pulling? Do we need to use a test stand?

A:

If you want to measure whether the required force for opening a package exceeds a certain reference value, you can hold and pull the sample simply by hand to measure the force and obtain the required data. But if you require more precise measurement results, a test stand will help you.

We will get in detail about this as follow.

To find out the difference in test results acquired by different test methods, we performed T-peel test shown like below, which is one of common peel test types to check opening forces of heal sealed packages.

For more detail about peel testing, please click here.

This T-peel test can be implemented by simply a hand or a test stand as well, The difference in measurement methods can have a significant effect on the test results, especially in terms of “Repeatability”. Let’s see the comparison in results below.

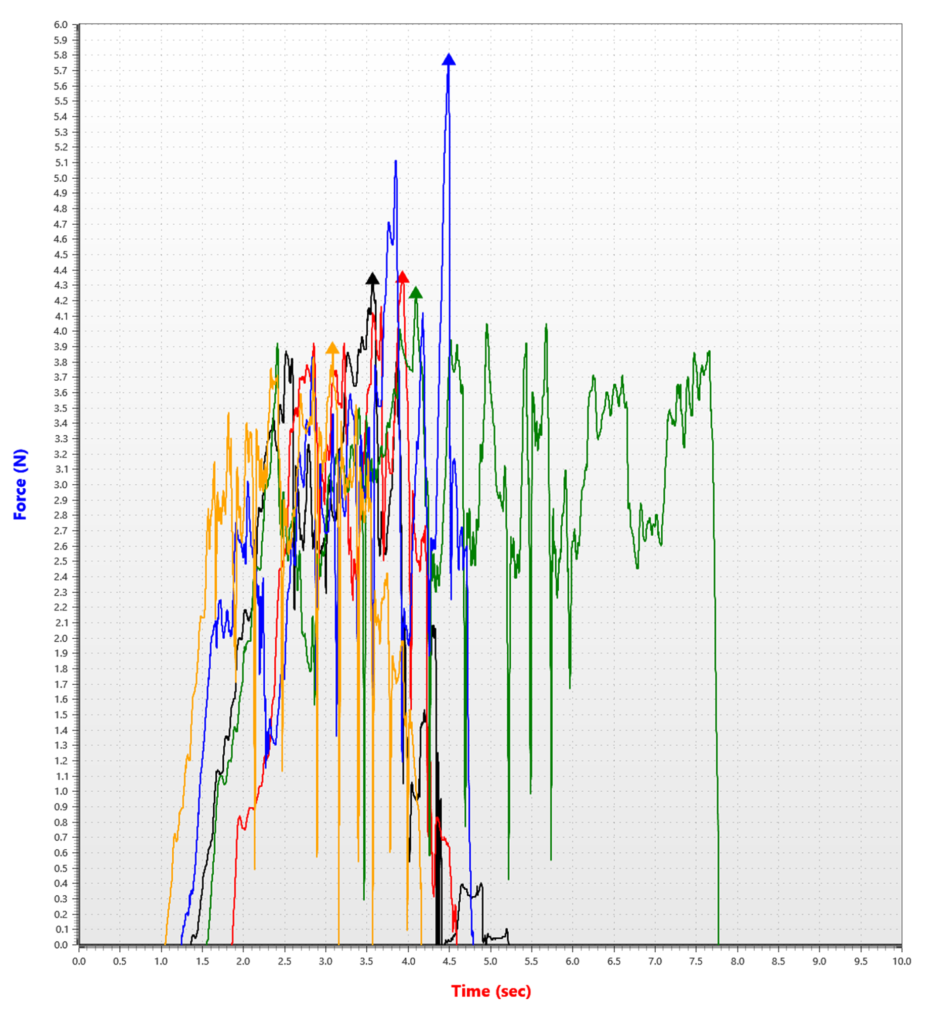

1. Hand pull measurement

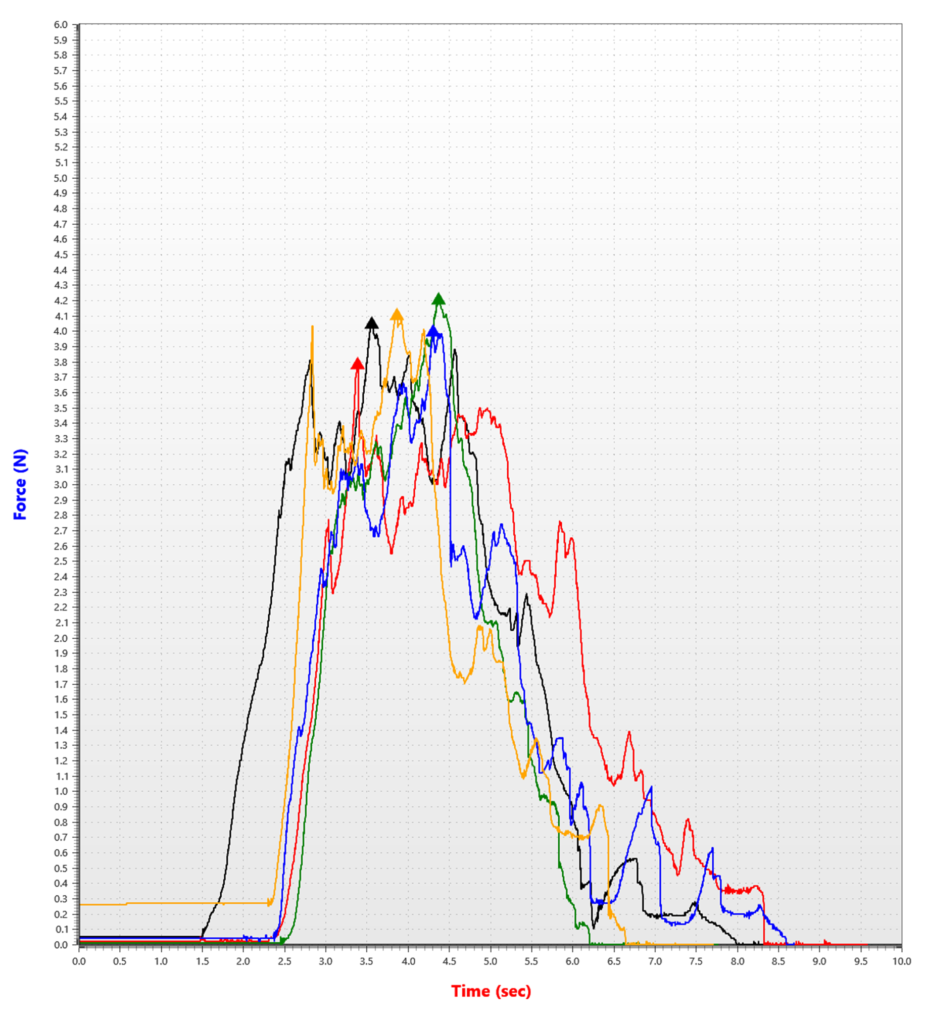

2. Measurement by using manual test stand

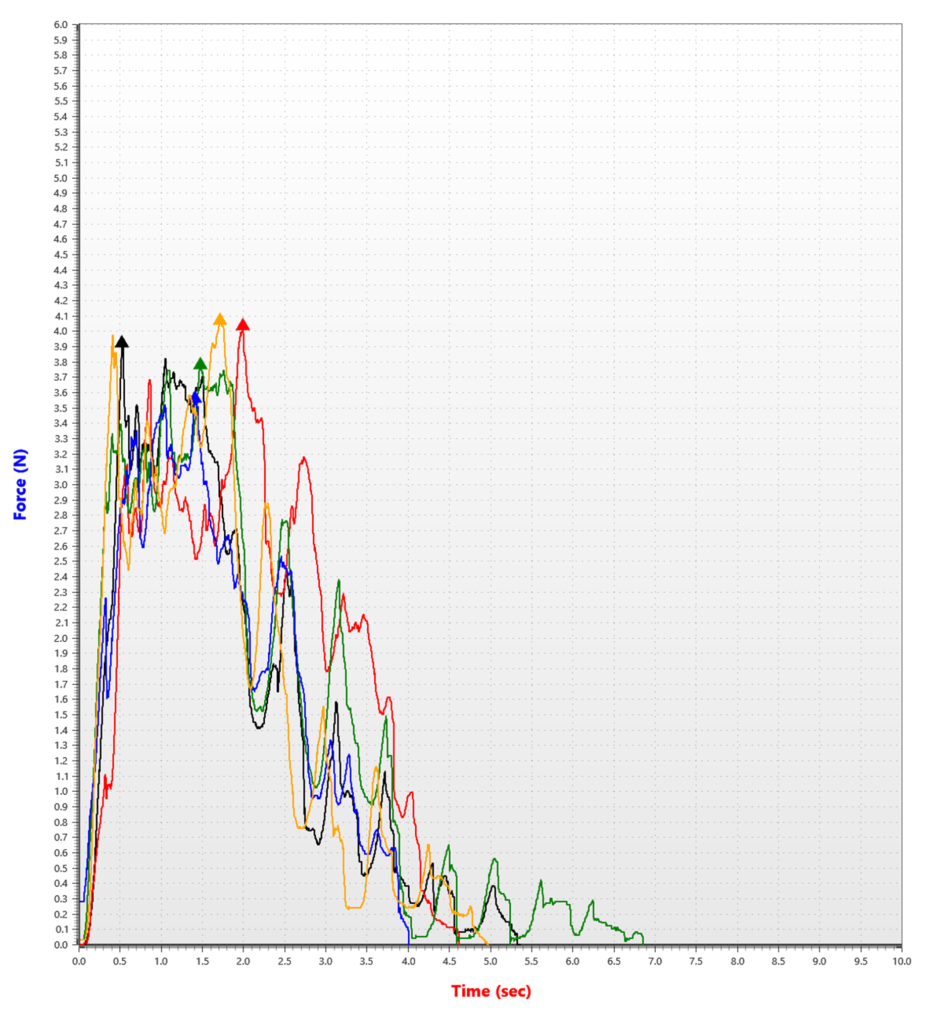

3. Measurement by using motorized test stand

Measured value(Number of samples:5)

| Hand pull | Manual Stand | Motorized Stand | |

| Sample1 | 4.33 | 4.04 | 3.92 |

| Sample2 | 4.34 | 3.78 | 4.03 |

| Sample3 | 4.24 | 4.20 | 3.78 |

| Sample4 | 5.76 | 3.99 | 3.56 |

| Sample5 | 3.88 | 4.10 | 4.07 |

| Average | 4.51 | 4.02 | 3.87 |

Graphs showing force value transition during measurement

As the results show, measurement by hand pull, the data variance increases due to the peak value and load transition. The reason is it is difficult to maintain the uniformity of measurement conditions, such as pulling force, pulling speed, and pulling direction etc. of each samples, which affect the measurement results.

On the other hand, the advantages of measurement by hand pull are you will be able to measure easily anywhere with low introduction costs. As we mentioned at the beginning, if you just want to measure whether the load value required for opening exceeds a certain reference value, hand pull measurement often meets the requirements.

However, when using a test stands for measurement, they will help us to achieve a wider range of precise measurements although high introduction costs needed. Unlike when measuring by hand pulling, using a test stand for measurement is easy to maintain the conformity of various measurement conditions. They help us reducing the variance in the measurement data and improving the repeatability. In addition, it is easy and safe to measure large loads or small feed amount that are difficult to measure by hand pulling.

There are 2 types of measurement stand, which are manual type and motorized type. Each type has different characteristics. The greatest feature of manual test stands is that they are small and do not require a power source, so they can be easily measured on a small tabletop. Furthermore, they are cheaper than motorized type.

On the other hand, motorized test stands are highly rigid. They use motors to control their movements, allowing them to standardize various test conditions more than manual test stands. And they help us perform measurements with the highest repeatability.

In peel tests, when using a manual test stand, differences in operation speed by the operator using the test stand may affect the results, so if you want to achieve higher repeatability, we recommend a motorized test stand.

Therefore, as shown in the results above, a test stand is a necessary product if you want to accurately check the load changes during the test. In addition, some models have programs that automatically repeat the same movements or apply a constant load, so they can be used for durability tests that are difficult to perform manually.

Above, we have introduced the points that must be considered when deciding on a measurement method and the characteristics of each method. All information can be summarized in a comparison table as follows.

| Items to consider | Handheld | Test stand | |

| Manual | Motorized | ||

| Repeatability | Low | Middle | High |

| Uniformity of speed | Bad | Fair | Excellent |

| Uniformity of direction | Bad | Good | Excellent |

| Introduction cost | Low | Middle | High |

| Small tabletop installation | Excellent | Good | Fair |

| No power supply required | Possible | Possible | Impossible |

| Measurement load | Low | Middle | High |

| Standards compliance | Bad | Bad | Excellent |

| Fine adjustment of feed amount | Bad | Fair | Excellent |

| Repeated measurements | Bad | Fair | Good |

| Keep constant load for a certain period | Bad | Bad | Good |

| Measurement of [load x displacement] | Bad | Bad | Good |

In addition, if you want to perform measurements that comply with ISO or JIS standards, the ability to meet prescribed conditions also be a factor to consider about in the measurement method. If you would like to confirm or consult about the optimal measurement method, please contact us here.