The 90-degree peel test and the 180-degree peel test are well-known methods for measuring the adhesive strength of adhesive tapes. However, the essential issue is which test should be performed?

In this article, we introduce the adhesive strength measurements under multiple conditions, in order to clarify the effects of peel angle and test speed on measurement results.

The Peel Angle Effect on The Measurement Results

Peel angle refers to the angle of the peeling direction relative to the adhesive surface of the adhesive tape. With the 90-degree peel test, peel angle is at 90 degrees when pulling the tape perpendicularly to the adhesive surface. With the 180-degree peel test, the folded tape is peeled at 180 degrees.

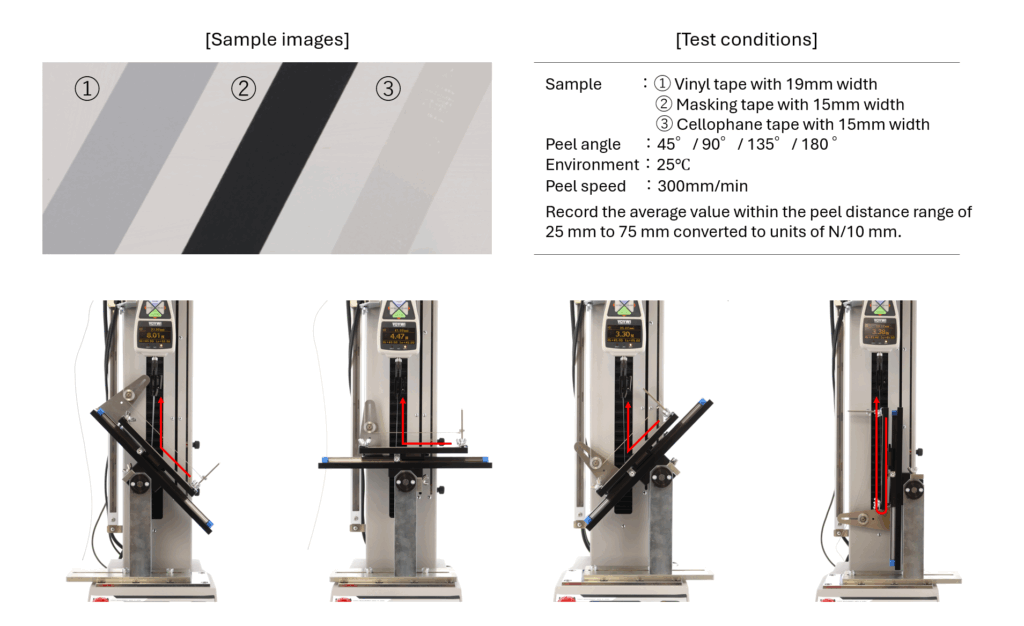

In this article, we performed peel tests with the peel angles of 45°, 90°, 135°, and 180°for three tapes. Tests were performed with the peel speed of 300mm/min and after peeling, approx. length of 100mm, the average force value required to peel was calculated for the peel distance of 25 to 75mm. Then the calculated average force value was converted to units of N/10mm (average force value (N) / sample width (mm) x 10mm).

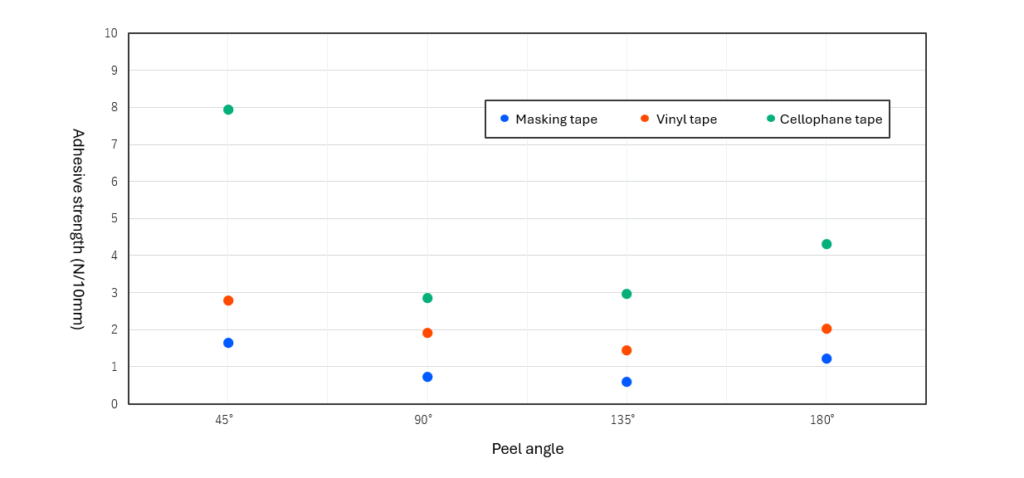

The individual peel angle measurement results are as follows. Although the result is based on the sample used, there is a certain uniformity identified regarding the increase or decrease in the adhered strength due to the peel angle differences.

| Peel Angle | 45° | 90° | 135° | 180° |

|---|---|---|---|---|

| Vinyl tape | 2.777N/10mm | 1.924N/10mm | 1.445N/10mm | 2.034N/10mm |

| Masking tape | 1.642N/10mm | 0.736N/10mm | 0.578N/10mm | 1.220N/10mm |

| Cellophane tape | 7.932N/10mm | 2.872N/10mm | 2.966N/10mm | 4.296N/10mm |

- Test at 45°the adhesive strength was the greatest in all tape types.

- The adhesive strength decreases as the peel angle increases from 45°. However, once it is beyond a certain angle, the adhesive strength tends to increase again. At the peel angles between 45°and 90°, The decrease in adhesive strength is particularly noticeable.

- The peel angles of 90°and 180°comparison, the adhesive strength is greater at 180°.

- The adhesive strength is obviously affected by the peel angle; however, the degree of effect varies depending on the samples used.

The Test Speed Effects on The Measurement Results

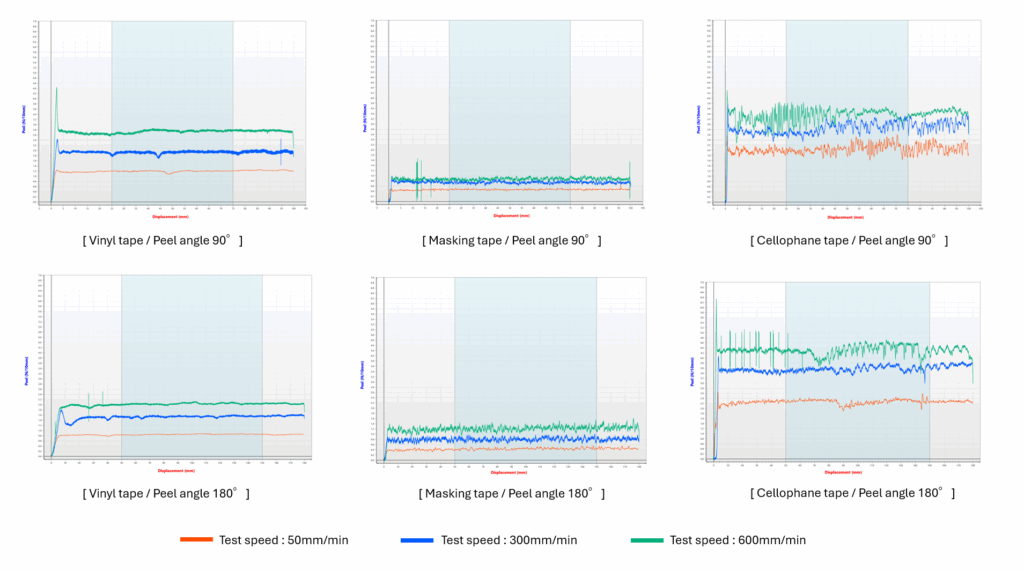

The following results are effect on the test speed on the adhesive strength. The Peel Test Standardsoften specify the test speeds of 300m/min or 600mm/min. In this case we performed the measurements at the speeds of 50mm/min, 300mm/min, and 600mm/min. All test conditions other than the speed were as above (the peel angle test), with the peel angle limited to 90°and 180°only.

[Peel at 90°angle]

| Test Speed | 50mm/min | 300mm/min | 600mm/min |

|---|---|---|---|

| Vinyl tape | 1.191N/10mm | 1.924N/10mm | 2.738N/10mm |

| Masking tape | 0.446N/10mm | 0.730N/10mm | 0.866N/10mm |

| Cellophane tape | 2.050N/10mm | 2.872N/10mm | 3.379N/10mm |

[Peel at 180°angle]

| Test Speed | 50mm/min | 300mm/min | 600mm/min |

|---|---|---|---|

| Vinyl tape | 0.853N/10mm | 1.540N/10mm | 2.034N/10mm |

| Masking tape | 0.438N/10mm | 0.804N/10mm | 1.220N/10mm |

| Cellophane tape | 2.269N/10mm | 3.566N/10mm | 4.296N/10mm |

The results show that regardless of the peel angles, the adhesive strength increases as the test speed increases. Also, from the graph, as the test speed increases the instability of the measurement values are identified. This may be due to the test stand vibrations, so for the comparisons of the minimum force value within ranges rather than the average value, the test results at a slower speed are suitable.

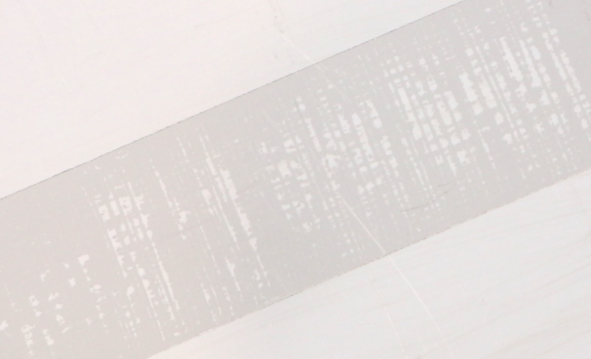

Besides vibration, other factors that can affect measurement value instabilities include the condition of the plate surface for adhering adhesive tape samples, scratches, or dirt on the surface. The graph above shows that the cellophane tape values at a test speed of 600 mm/min showing obvious instability. The cellophane tape used in this test is prone to streaky air bubbles remaining in the sample adhered. (The image is for illustrative purposes only. In actual measurements, the samples are adhered to minimize the air bubbles.)

Summary

In this article, we have introduced actual measurement results on the effects of peel angle and test speed on adhesive strength measurements. Although the examples presented are limited to the samples used, we hope you will find them useful as reference values.

As introduced, force measurement results are often significantly affected by test conditions. In addition to peel angle and test speed, factors such as temperature and other measurement environments can also affect the results. Force Channel is currently verifying the effect of temperature using a heated stage. Once this verification is complete, we will add the information to this article, so please check back.

>>Measurement example video: 90-degree peel test of adhesive tape

>>Measurement example video: 180-degree peel test of adhesive tape