Q: What are the appropriate measurement methods available for adhesive strength evaluation for choosing the appropriate adhesives for bonding resins? Also, is there an additional advice on any cautionary points to note for this specific measurement?

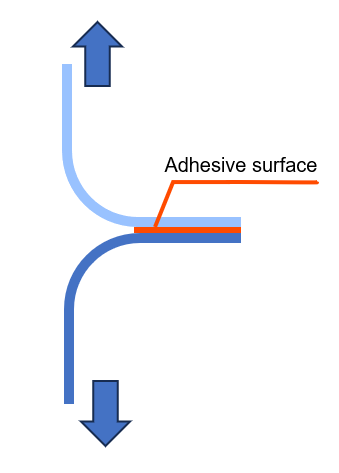

A: For any adherents with deform difficulties, Tensile Tests and Lap Shear Tests are generally recommended for evaluation. For any adherents with easy-to-deform characteristics, such as films, T-peel tests are popular for evaluating adhesive strength.

| Tensile Test | Lap Shear Test | T-Peel Test |

|---|---|---|

|  |  |

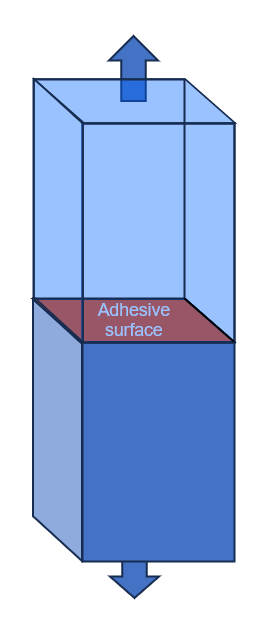

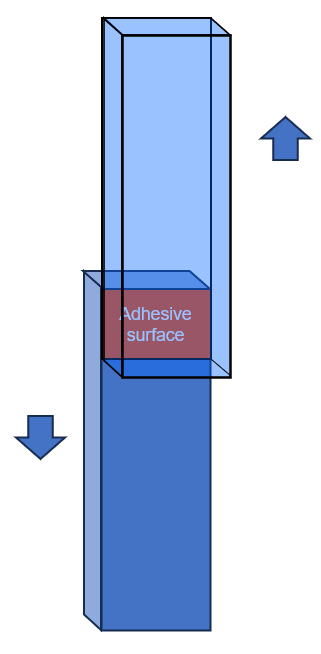

| Measures the breaking strength by applying a tensile force perpendicular to the adhesive surface. | Measures the breaking strength by applying a horizontal tensile force to the adhesive surface. | A method to pull and peel apart the bonded material to measure its breaking strength. |

The test method selected should be considered based on the force types and how they are applied to the adhesive surface during actual use. In addition, some standards, such as ISO, may specify measurement methods depending on the adherents. Hence, for the measurements performed in accordance with the standard, it is necessary to meet the standard’s requirements by selecting the appropriate test methods.

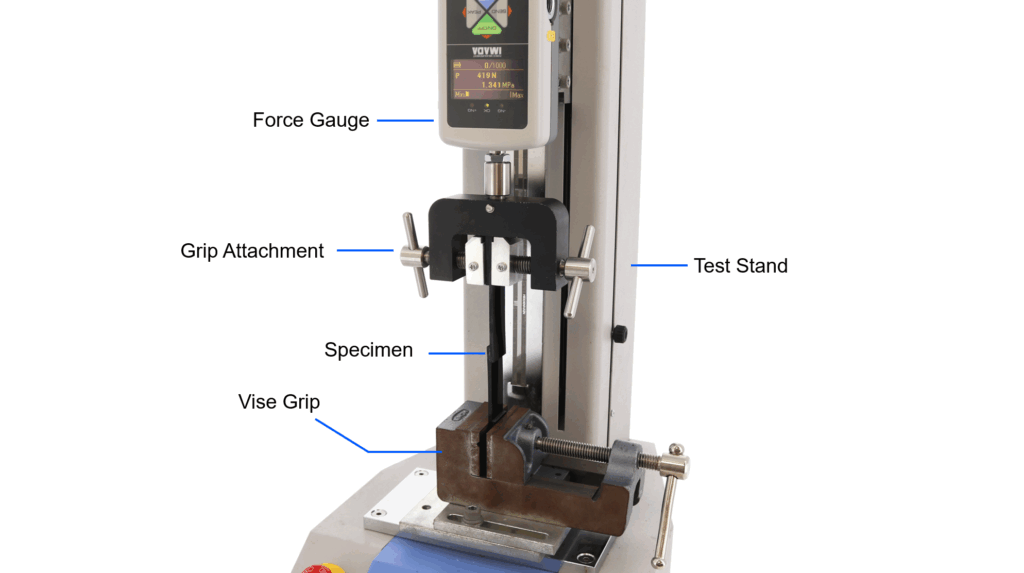

In this article, we will introduce the Lap Shear Test, which is the one with most inquiries among the above three. In the lap shear test, two long vertical plates and overwrapped ends are glued together, and they are pulled vertically, the force applied to pull the 2 pcs apart from the glued surface to measure the tensile force. Generally, a motorized test stand is used to apply the force, and a force gauge is used to measure the force value.

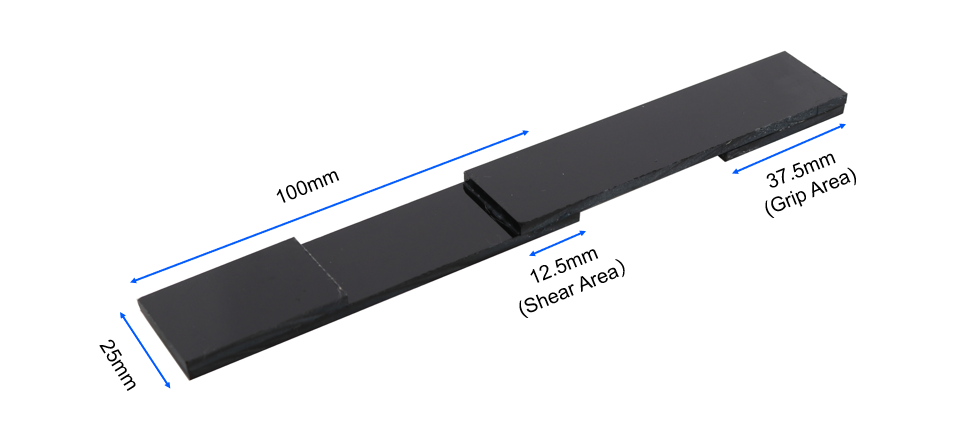

The size of the sample and the adhered area must be considered depending on the measurement purpose. For instance, the JIS K 6850: 1999 specification requires the sample size and adhesive area as below:-

The amount of adhesive required to apply and the curing time will vary depending on the adhesive; please refer and follow the specification on the adhesives used for the correct usage as well as the standards and regulations requirements of your company and the industry standards and requirements.

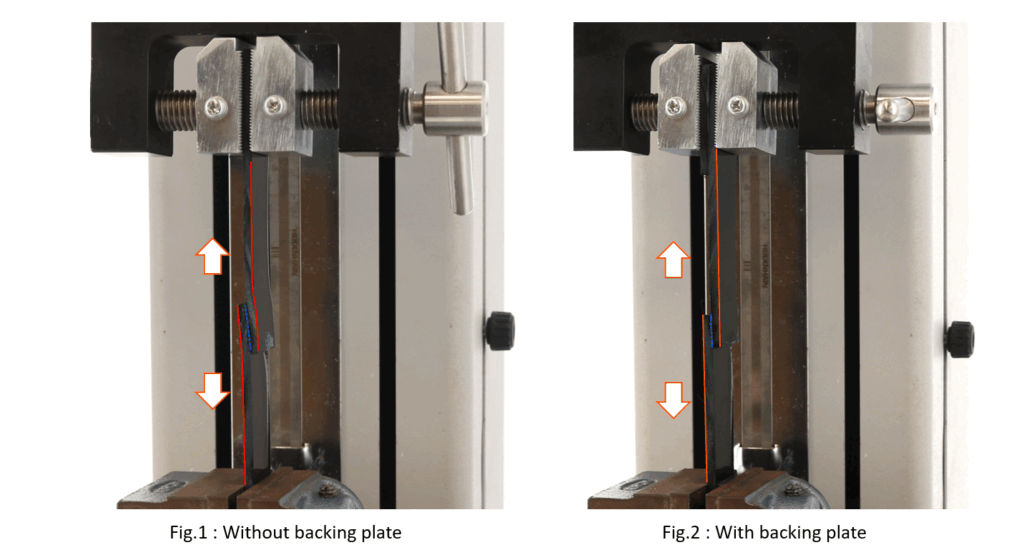

When conducting the test, care must be taken to avoid any load application other than the shear direction to the adhesive surface. The gripping sections of the lap shear test samples are not aligned straight to the adhesive surface. Therefore, if the sample is gripped with both ends aligned with the center line of the chuck, the sample will bend, and there would be additional load other than the shear applied to the adhesive surface.

This issue is solved by placing a backing plate: same thickness as the sample on the gripping section.

The adhesive surface can be aligned in a tensile direction, helping to minimize the loads on the adhesive surface in directions other than the shear direction. Furthermore, in order to stabilize the backing plate, the adhesive can be applied to fix the sample to avoid slipping.

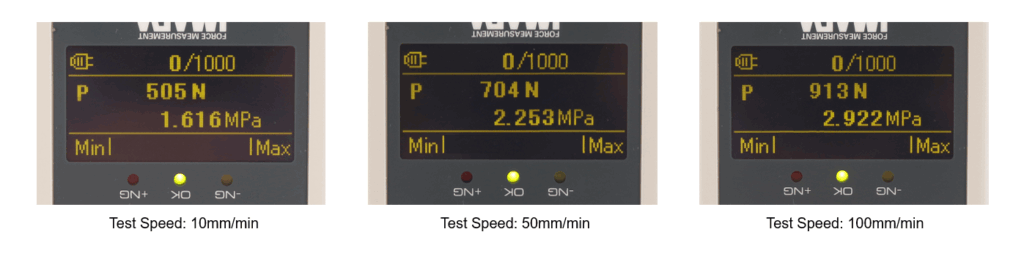

It is also essential to note that test speed affects the test results. (Faster the test speed, greater the breaking strength. Additionally, unitability is often identified in the values measured.)

JIS K 6850: 1999 states that the test should be performed at a “constant speed at which the adhesive joint breaks in 65 seconds ± 20 seconds,” and adhesive strength tests are generally performed at a low speed of around 10 mm/min or less.

Measurement results are recorded as “N” breaking force or “MPa” breaking stress. Breaking stress (MPa) can be calculated by dividing the breaking force (N) by the adhesive area (mm2).

Calculating breaking stress enables understanding of the adhesive characteristics, which is helpful for adhesive strength calculation for the actual use and the test result comparisons with the different sample sizes as such.

This concludes one of the measurement examples of the “lap shear test,” introducing a method for adhesive strength evaluation. Force Channel introduces a variety of helpful information on force measurement and measurement examples. The article below is on “How to Choose the Best Grip Fixtures for Tension Test?” describing selecting a chuck jig suitable for tensile testing. Please take this opportunity to look up other articles for additional references.